A kind of liquid photosynthetic bacteria high vigor preservation method

A technology of photosynthetic bacteria and preservation methods, applied in the direction of microorganism-based methods, biochemical equipment and methods, preservation of microorganisms, etc., can solve the problems of increasing production processes and production costs, not suitable for large-scale production, and large loss of vitality, etc., to achieve Eliminate the risk of secondary pollution, good vitality preservation effect, and low preservation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

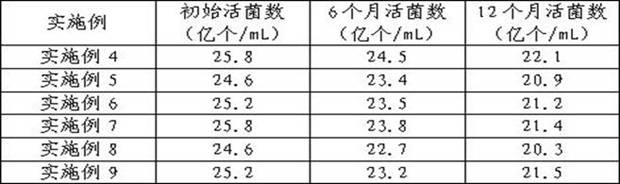

Examples

Embodiment 1

[0033] The preparation of liquid photosynthetic bacteria comprises the following steps:

[0034] (1) Preparation of seed culture solution: weigh the following components in parts by weight: 3 parts of sodium acetate, 1 part of sodium bicarbonate, 1 part of ammonium chloride, 0.5 parts of dipotassium hydrogen phosphate, 0.2 parts of magnesium chloride, Ferrous-EDTA 0.005 parts, sodium chloride 5 parts, distilled water 1000 parts, mix well, adjust the pH value to 7.4±0.2, steam sterilize at 121°C for 15min, cool to 30°C, and set aside;

[0035](2) Preparation of expanded culture medium: Weigh the following components in parts by weight: 4 parts of sodium acetate, 1.5 parts of sodium bicarbonate, 1.5 parts of ammonium chloride, 0.6 parts of dipotassium hydrogen phosphate, 0.25 parts of magnesium chloride, Ferrous-EDTA 0.006 parts, sodium chloride 6 parts, drinking water 1100 parts, mix well, adjust the pH value to 7.4±0.2, steam sterilize at 121°C for 15min, cool to 30°C, and set...

Embodiment 2

[0040] The preparation of liquid photosynthetic bacteria comprises the following steps:

[0041] (1) Preparation of seed culture solution: Weigh the following components in parts by weight: 2 parts of sodium acetate, 1.5 parts of sodium bicarbonate, 0.5 parts of ammonium chloride, 0.6 parts of dipotassium hydrogen phosphate, 0.25 parts of magnesium chloride, Ferrous-EDTA 0.004 parts, sodium chloride 5 parts, distilled water 900 parts, mix well, adjust the pH value to 7.4±0.2, steam sterilize at 121°C for 15min, cool to 30°C, and set aside;

[0042] (2) Preparation of expanded culture medium: Weigh the following components in parts by weight: 3 parts of sodium acetate, 1 part of sodium bicarbonate, 1 part of ammonium chloride, 0.6 part of dipotassium hydrogen phosphate, 0.15 part of magnesium chloride, 0.15 part of magnesium chloride, Ferrous-EDTA 0.005 parts, sodium chloride 4 parts, drinking water 950 parts, mix well, adjust the pH value to 7.4±0.2, steam sterilize at 121°C f...

Embodiment 3

[0047] The preparation of liquid photosynthetic bacteria comprises the following steps:

[0048] (1) Preparation of seed culture solution: Weigh the following components in parts by weight: 4 parts of sodium acetate, 0.5 parts of sodium bicarbonate, 1.5 parts of ammonium chloride, 0.4 parts of dipotassium hydrogen phosphate, 0.2 parts of magnesium chloride, Ferrous-EDTA 0.006 parts, sodium chloride 4 parts, distilled water 1000 parts, mix well, adjust the pH value to 7.4±0.2, steam sterilize at 121°C for 15min, cool to 30°C, and set aside;

[0049] (2) Preparation of expanded culture medium: Weigh the following components in parts by weight: 3 parts of sodium acetate, 1 part of sodium bicarbonate, 1 part of ammonium chloride, 0.5 parts of dipotassium hydrogen phosphate, 0.2 parts of magnesium chloride, Ferrous-EDTA 0.005 parts, sodium chloride 5 parts, drinking water 1000 parts, mix well, adjust the pH value to 7.4±0.2, steam sterilize at 121°C for 15min, cool to 30°C, and set...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com