Makeup removing soap with plant botanical component extracting solution and manufacturing method for same

A technology of plant ingredients and production methods, which is applied in the manufacture of soap solutions, soap detergents and other compounding agents, cosmetic preparations, etc., can solve problems such as skin whitening effects that are not mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

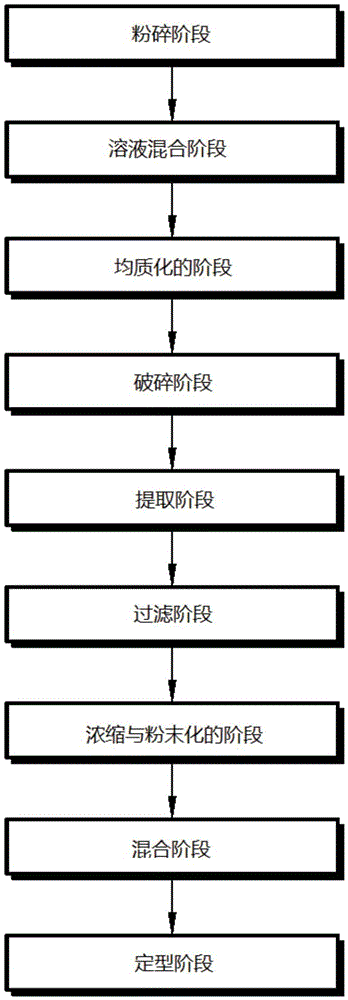

[0035] Embodiment 1. Soap making method

[0036] (1) Crushing stage

[0037] The plant raw materials Lycium barbarum, Alkaline flower, Houttuynia cordata, Artichoke, Licorice are crushed.

[0038] According to the needs, choose the following tools for crushing: Rotary Crusher, Jaw Crusher, Roll Crusher, Cone Crusher, Hammer Crusher, Impact Crusher Impactcrusher, Hammermill, Rodmill, Ballmill, Raymondmill, Supermill, Rollmi, Pin mill, Jet mill, Conical ball mill or Vibration mill.

[0039] It can be crushed into 1~100mesh size, and various settings can be made according to the design conditions.

[0040] For the situation that it cannot be completely crushed under different setting conditions, the crushing stage needs to be repeated more than 2 times.

[0041] (2) Solution mixing stage

[0042] A mixing stage in which organic and inorganic solutions are added to the comminuted vegetable raw material.

[0043] In the stage of using organic solution and inorganic solution, ...

reference example 1

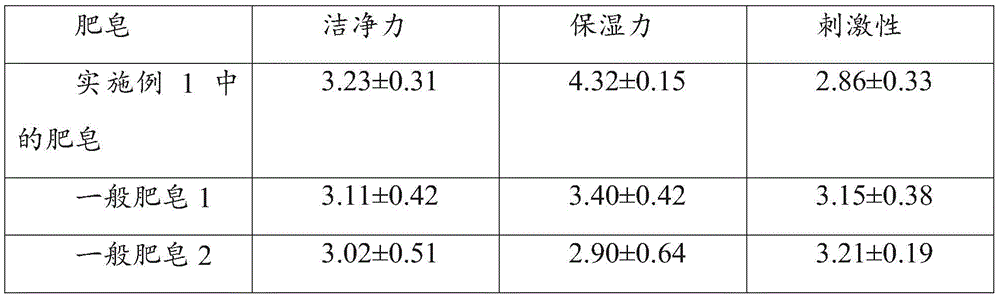

[0079] Reference example 1. Efficacy evaluation for the use of soap

[0080] In order to evaluate the effectiveness of the use of the soap of the present invention, it was evaluated from the aspects of cleansing power, moisturizing power and irritation.

[0081] The evaluation is to use the soap obtained under the conditions described in the specific embodiment 1 and conduct a control experiment with two kinds of soaps sold on the market, and select 25 adults as objects.

[0082] The evaluation method is that users who have applied cosmetics clean with each soap separately, and conduct a questionnaire survey on the feeling after cleansing from the perspectives of cleansing power, moisturizing power and irritation.

[0083] The evaluation of cleansing power is based on questionnaire evaluations such as the feeling after cleansing, smoothness, stickiness, etc., the residual feeling of cosmetics, and the degree of cosmetic removal.

[0084] Moisturizing power refers to the quest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com