Thermal storage PP resin-based composite shoe material and preparation method thereof

A resin-based, heat storage technology, applied in footwear, applications, clothing, etc., can solve the problems of lack of heat storage function, poor heat storage and warmth retention, etc., to improve light-to-heat conversion performance, improve heat storage performance, improve phase capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

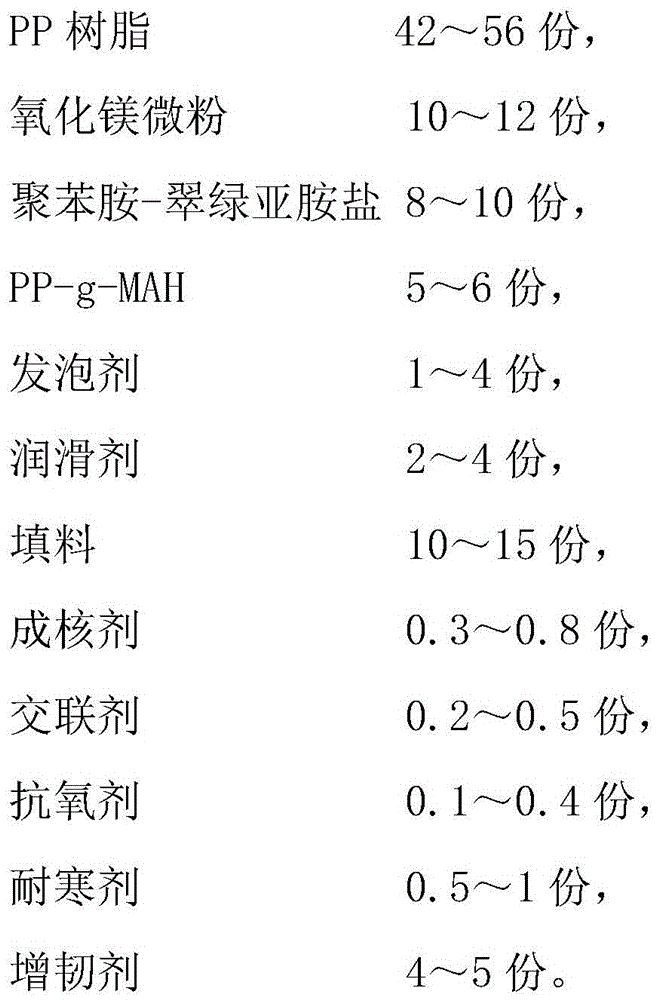

Method used

Image

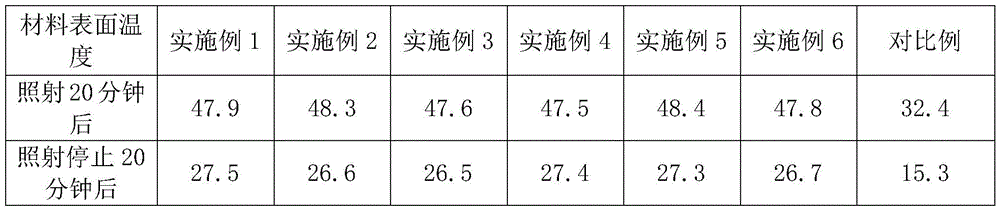

Examples

Embodiment 1

[0028] A heat storage PP resin-based composite shoe material, based on parts by weight, made of the following components: 45 parts of PP resin, 10.5 parts of magnesium oxide powder, 9.5 parts of polyaniline-emeraldine salt, PP-g-MAH5. 5 parts, 4 parts DIAD, 2.5 parts stearamide, 14 parts talc, 0.3 parts organic phosphate nucleating agent, 0.3 parts dicumyl peroxide, 10100.2 parts antioxidant, 0.7 parts dioctyl azelate , MBS4.2 copies.

[0029] The steps of the preparation method are as follows:

[0030] (1) Dissolve magnesium oxide powder in deionized water. The volume ratio of magnesium oxide powder to deionized water is 1:3. After stirring for 2 hours, a uniform magnesium oxide slurry is obtained. Add glycerol monostearate to the oxidation Stir the magnesium slurry at 65°C for 3.5 hours. The mass ratio of glycerol monostearate to the magnesium oxide slurry is 1:9. After the material is discharged, it is suction filtered, washed, and dried in a vacuum drying oven at 100°C for 5 h...

Embodiment 2

[0034] A heat storage PP resin-based composite shoe material, based on parts by weight, made of the following components: 55 parts of PP resin, 11 parts of magnesium oxide powder, 9 parts of polyaniline-emeraldine salt, PP-g-MAH5. 2 parts, 3 parts DIAD, 2 parts stearamide, 12 parts mica powder, 0.5 parts organic phosphate nucleating agent, 0.4 parts dicumyl peroxide, 10100.3 parts antioxidant, 0.8 parts dioctyl azelate , MBS 4 copies.

[0035] The steps of the preparation method are as follows:

[0036] (1) Dissolve magnesium oxide powder in deionized water. The volume ratio of magnesium oxide powder to deionized water is 1:3. After stirring for 2 hours, a uniform magnesium oxide slurry is obtained. Add glycerol monostearate to the oxidation Stir the magnesium slurry at 65°C for 3.5 hours. The mass ratio of glycerol monostearate to the magnesium oxide slurry is 1:9. After the material is discharged, it is suction filtered, washed, and dried in a vacuum drying oven at 100°C for 5 h...

Embodiment 3

[0040] A heat storage PP resin-based composite shoe material, based on parts by weight, made of the following components: 56 parts of PP resin, 11.5 parts of magnesium oxide powder, 10 parts of polyaniline-emeraldine salt, 5 parts of PP-g-MAH , 3.5 parts of DIAD, 3.5 parts of stearamide, 10 parts of mica powder, 0.7 parts of organic phosphate nucleating agent, 0.2 parts of dicumyl peroxide, 10100.1 parts of antioxidants, 1 part of dioctyl azelate , MBS4.5 copies.

[0041] The steps of the preparation method are as follows:

[0042] (1) Dissolve magnesium oxide powder in deionized water. The volume ratio of magnesium oxide powder to deionized water is 1:3. After stirring for 2 hours, a uniform magnesium oxide slurry is obtained. Add glycerol monostearate to the oxidation Stir the magnesium slurry at 65°C for 3.5 hours. The mass ratio of glycerol monostearate to the magnesium oxide slurry is 1:9. After the material is discharged, it is suction filtered, washed, and dried in a vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com