A kind of multi-gradient functionalized microcapsule titanium phosphate flame retardant and preparation method thereof

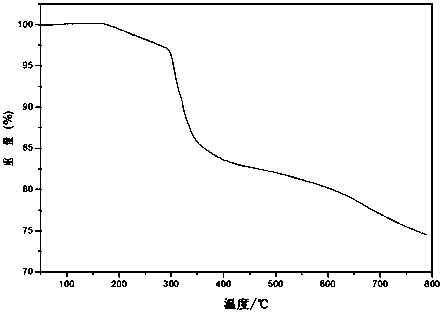

A technology of titanium phosphate and microcapsules, which is applied in the field of flame retardant modification, can solve the problems of catalytic char formation, non-catalysis, and complicated preparation process, and achieve enhanced mechanical strength, high char formation, and high thermal stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Preparation of titanium phosphate:

[0037] Mix 10 g of titanium tetrachloride with 100 ml of distilled water evenly, add 100 ml of 9M phosphoric acid while mechanically stirring, and transfer the mixed solution into a stainless steel reaction kettle with a polytetrafluoroethylene liner. After reacting under high pressure for 72 hours, cool to room temperature, wash with deionized water repeatedly until the pH of the solution is neutral, and then vacuum dry at 80°C to obtain titanium phosphate powder;

[0038] (2) Intumescent flame retardant coated inner wall:

[0039] Weigh 10 g of titanium phosphate powder obtained in step (1), disperse it in 100 ml of tetrahydrofuran, stir it mechanically and raise the temperature to 100 °C, weigh a certain amount of pentaerythritol as a carbon source modifier, and add it to the above solution After raising the temperature to 150 °C and mechanically stirring for 2 h, add a certain amount of ammonium phosphate as the acid source ...

Embodiment 2

[0043] (1) Preparation of titanium phosphate:

[0044] Mix 10 g of titanium tetrachloride with 100 ml of distilled water evenly, add 100 ml of 9M phosphoric acid while mechanically stirring, and transfer the mixed solution into a stainless steel reaction kettle with a polytetrafluoroethylene liner. After reacting under high pressure for 72 hours, cool to room temperature, wash with deionized water repeatedly until the pH of the solution is neutral, and then vacuum dry at 80°C to obtain titanium phosphate powder;

[0045] (2) Intumescent flame retardant coated inner wall:

[0046] Weigh 10 g of titanium phosphate powder obtained in step (1), disperse it in 100 ml of tetrahydrofuran, stir it mechanically and raise the temperature to 100 °C, weigh a certain amount of pentaerythritol as a carbon source modifier, and add it to the above solution After raising the temperature to 150 °C and mechanically stirring for 2 h, add a certain amount of ammonium phosphate as the acid source ...

Embodiment 3

[0052] (1) Preparation of titanium phosphate:

[0053] Mix 10 g of titanium tetrachloride with 100 ml of distilled water evenly, add 100 ml of 9M phosphoric acid while mechanically stirring, and transfer the mixed solution into a stainless steel reaction kettle with a polytetrafluoroethylene liner. After reacting under high pressure for 72 hours, cool to room temperature, wash with deionized water repeatedly until the pH of the solution is neutral, and then vacuum dry at 80°C to obtain titanium phosphate powder;

[0054] (2) Intumescent flame retardant coated inner wall:

[0055] Weigh 10 g of titanium phosphate powder obtained in step (1), disperse it in 100 ml of tetrahydrofuran, stir it mechanically and raise the temperature to 100 °C, weigh a certain amount of pentaerythritol as a carbon source modifier, and add it to the above solution After raising the temperature to 150 °C and mechanically stirring for 2 h, add a certain amount of ammonium phosphate as the acid source ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com