Swage disposal system for ship and disposal method of swage disposal system

A sewage treatment system and marine technology, applied in water/sewage treatment, biological water/sewage treatment, light water/sewage treatment, etc., to achieve the effects of convenient operation, low energy consumption, and short hydraulic retention time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

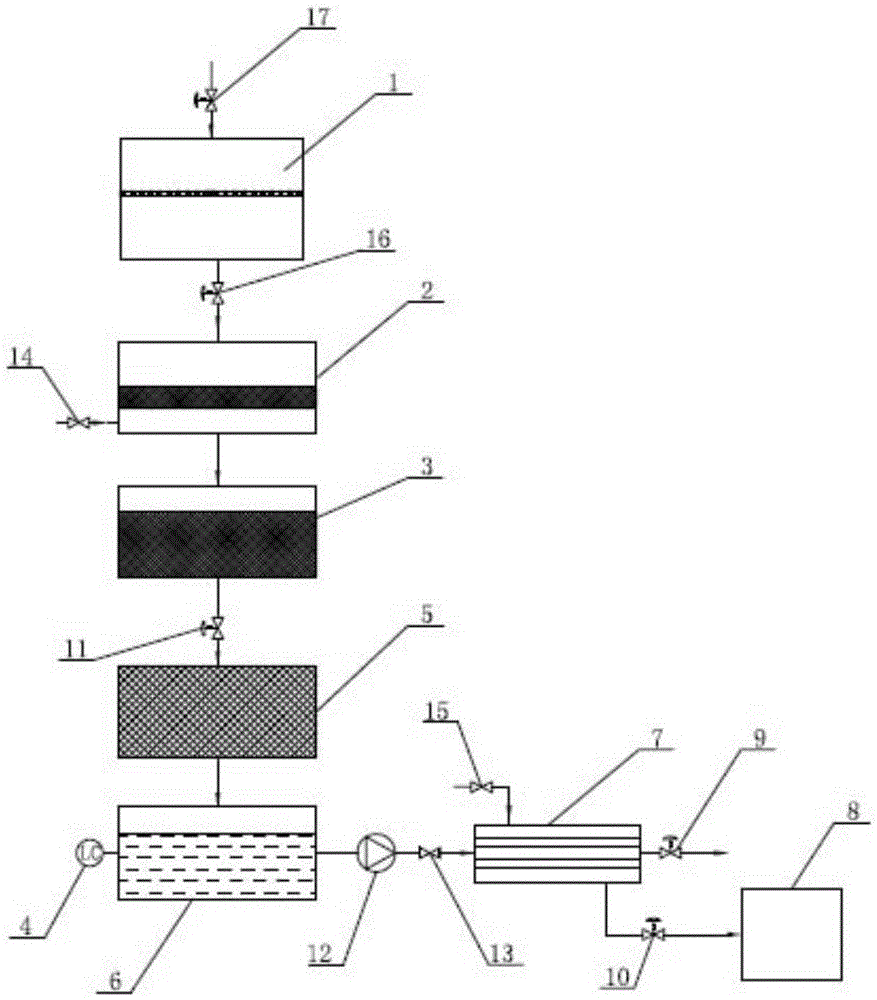

[0038] Such as figure 1 As shown, the present invention provides a marine sewage treatment system, which includes an oil-water separator 1, a precision filter 2, a resin adsorption system 3, an MBR membrane bioreactor 5, a liquid buffer tank 6, a membrane separation device 7 and ultraviolet sterilizing device 8; the oil-water separator 1, precision filter 2, resin adsorption system 3, MBR membrane bioreactor 5, liquid buffer tank 6, membrane separator 7 and ultraviolet sterilizing device 8 are all provided with inlets and export;

[0039] The outlet of the oil-water separator 1 is connected with the inlet of the precision filter 2, the outlet of the precision filter 2 is connected with the inlet of the resin adsorption system 3, and the outlet of the resin adsorption system 3 is connected with the MBR membrane bioreactor 5, the outlet of the MBR membrane bioreactor 5 is connected with the inlet of the liquid buffer tank 6, and the outlet of the liquid buffer tank 6 is connect...

Embodiment 2

[0058] The difference between embodiment 2 and embodiment 1 is:

[0059] The residence time of sewage in precision filter 2 is 50min. The saturated adsorption volume of the resin in the resin adsorption system 3 is 80 times the volume of the resin.

Embodiment 3

[0061] The difference between embodiment 3 and embodiment 1 is:

[0062] The residence time of sewage in precision filter 2 is 120min. The saturated adsorption volume of the resin in the resin adsorption system 3 is 120 times the volume of the resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com