A braking system for freight trains

A technology for freight trains and braking systems, applied in the field of braking systems for freight trains, can solve the problems of difficulty in ensuring railway transportation safety, increased wear of brake shoes, and increased operating costs, so as to reduce power and wear of brake shoes, improve Braking performance, compact structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

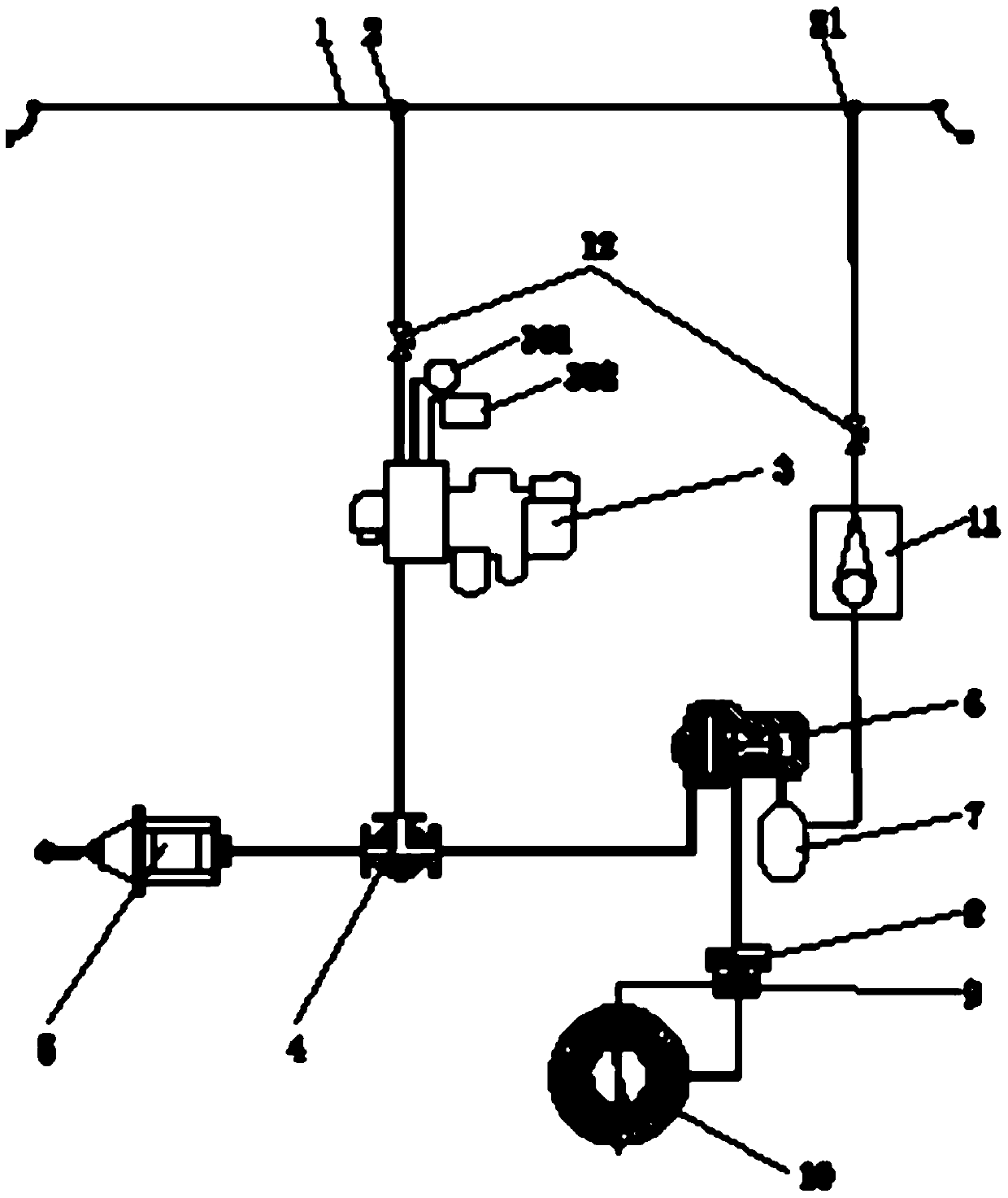

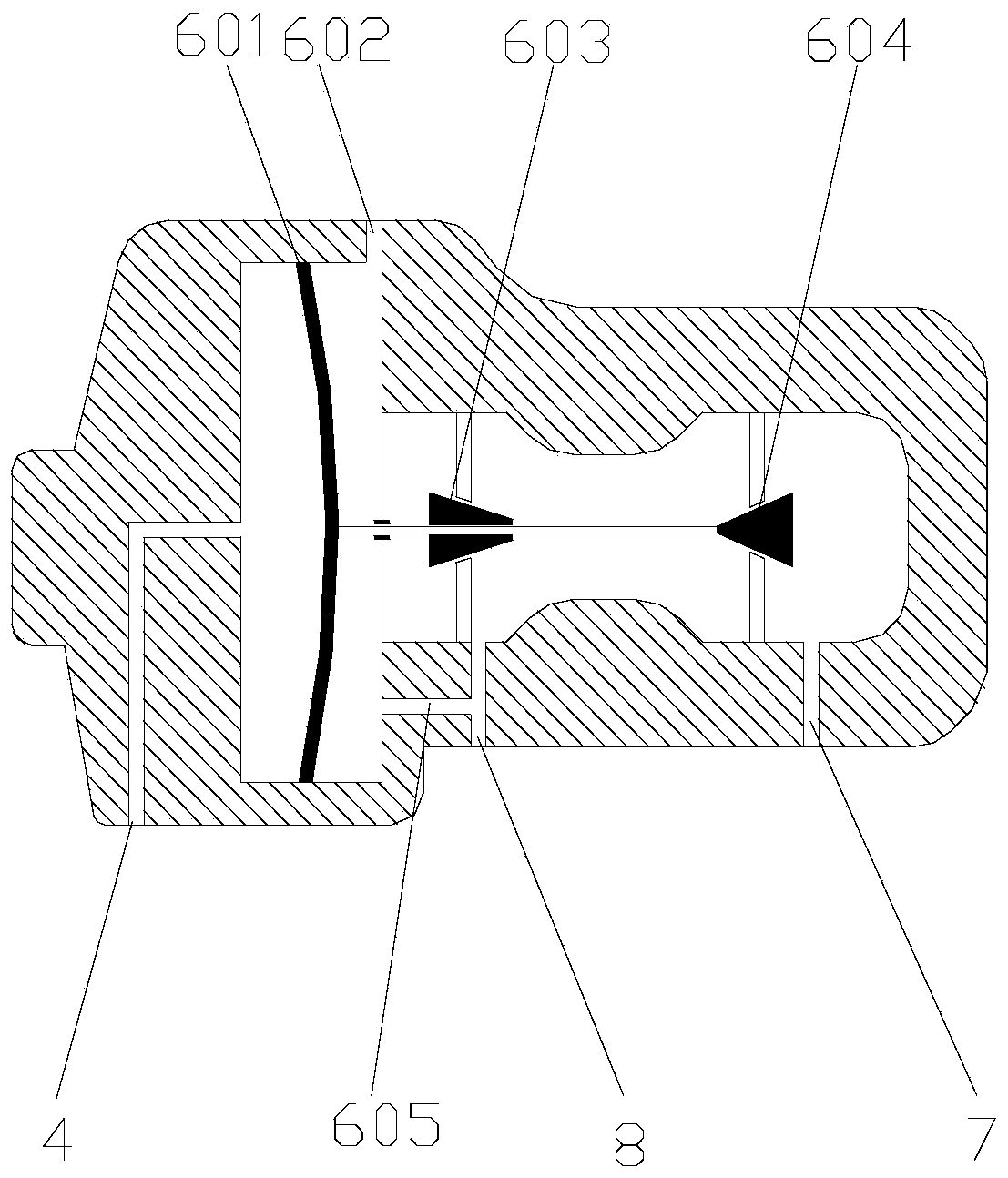

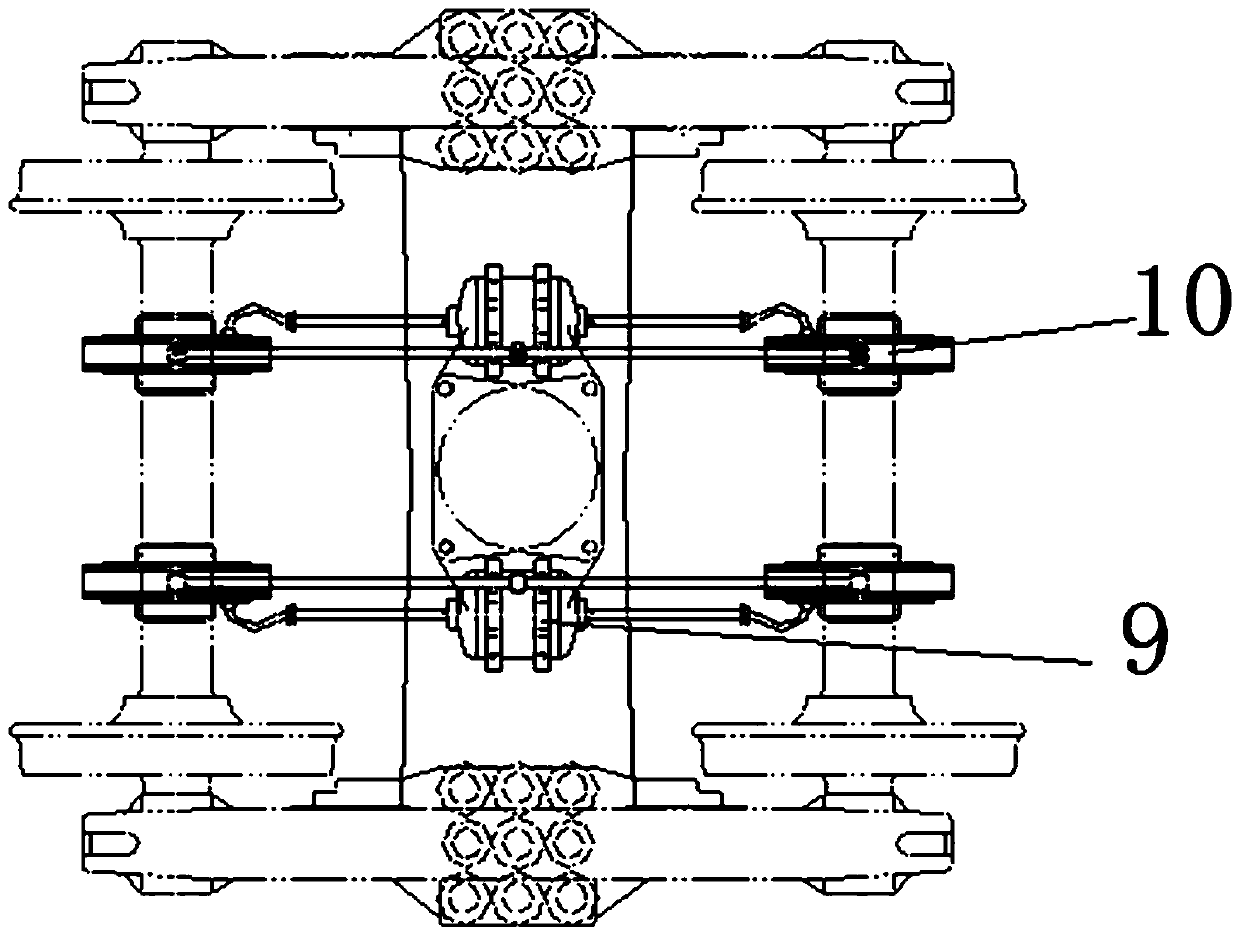

[0044] Such as figure 1 As shown, a brake system for freight trains includes an air brake mechanism, a three-way valve 4 and a hydraulic damper brake mechanism. The air brake mechanism includes a 120-type air distribution valve 3 and a brake cylinder 5, The 120-type air distribution valve 3 is respectively connected to the train pipe 1 and the brake cylinder 5 through the first brake branch pipe 2. It is also connected to the auxiliary air cylinder 301 and the acceleration release air cylinder 302. The brake cylinder 5 transmits the force to the cargo train. The brake shoe and the inlet of the three-way valve 4 are connected to the air distribution valve 3 through the original pipeline leading to the brake cylinder, and the two outlets are respectively connected to the brake cylinder 5 and the brake mechanism of the hydraulic damper.

[0045...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com