Position detection system

A detection system and detection device technology, used in length measuring devices, metal processing equipment, metal rolling, etc., can solve the problems of shutdown, low detection accuracy, no signal output from limit switches, etc., and achieve detection position preparation and precision control. , the effect of improving the coefficient of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

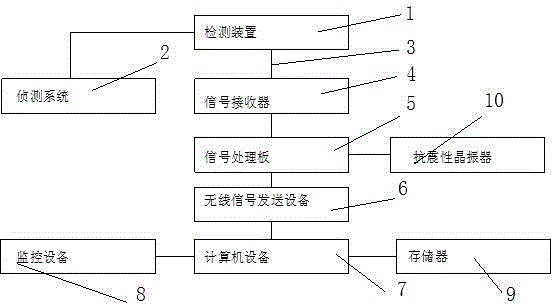

[0012] Such as figure 1 As shown, the present invention: a position detection system, including a detection device 1, the detection device 1 is connected to the detection system 2, the detection device 1 is connected to the signal receiver 4 through the optical waveguide 3, and the signal receiver 4 is connected to the signal processing through the optical waveguide 3 The board 5 and the signal processing board 5 are connected to the computer equipment 7 through the wireless signal sending equipment 6, and the computer equipment 7 is provided with a monitoring equipment 8. A storage device 9 is provided in the computer device 7 . The signal processing board 5 is provided with an anti-vibration crystal oscillator 10 . The detection position is prepared, the precision control is precise, and the precision coefficient of the system is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com