Installation method for replacing the guide rail of the sector section of the continuous casting machine

A continuous casting machine segment and installation method technology, which is applied in the field of metallurgical equipment installation, can solve the problems of heavy workload, large installation measurement data, and long time consumption, and achieve the effects of short time consumption, precise precision control, and convenient implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale.

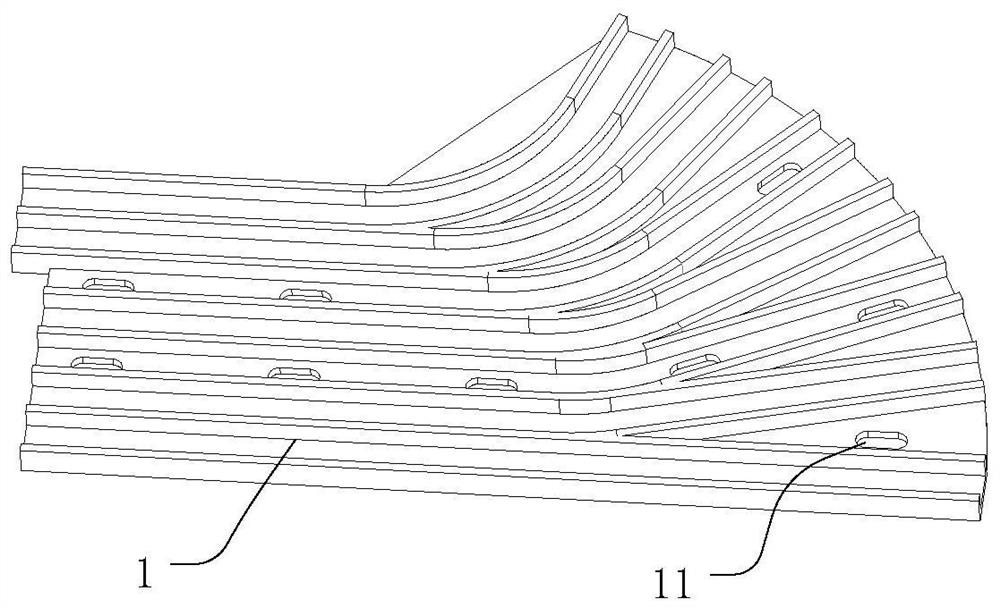

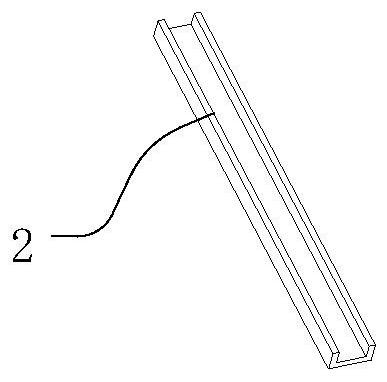

[0035] The sectors of the continuous casting machine are equipped with sector replacement guide rails, which include a first sector unit and a second sector unit, the first sector unit and the second sector unit are arranged parallel to each other and at a preset distance, and the first sector The unit and the second fan-shaped unit respectively include a replacement guide rail upper assembly 1 and a plurality of replacement guide rail lower sections 2 connected to the replacement guide rail upper assembly 1 . The structure of replacing the guide rail upper assembly 1 is as follows figure 1 As shown, the structure of the lower section 2 of the replacement guide rail i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com