A wet chemical oxidation waste gas treatment device

A technology of waste gas treatment and wet chemistry, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, can solve the problems of insufficient use of oxidants, insufficient exposure of pollutants, and low efficiency of pollutant degradation. The effect of small area, thorough decomposition and wide range of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

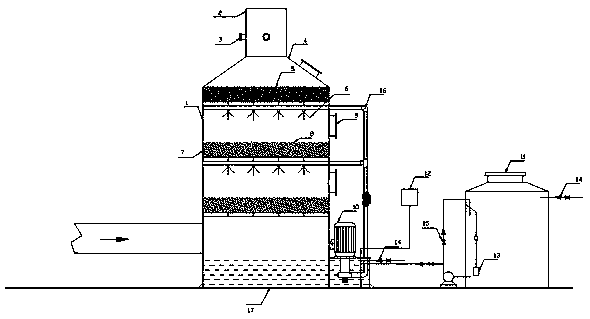

[0013] like figure 1 As shown, a wet chemical oxidation waste gas treatment device includes a demisting bed 4, a catalytic packing bed 7, a packing 8 and a dosing pump 11, the demistering bed 4 is provided with a demisting filler 5, and the demistering The bottom of the bed 4 is provided with the catalytic packing bed 7, the inside of the catalytic packing bed 7 is provided with a packing 8, and the packing 8 is a solid catalyst, and one side of the demister bed 4 and the catalytic packing bed 7 are provided with Observation window 9, described demisting bed 4 and described catalytic packing bed 7 are all arranged in oxidation tower 1, and described oxidation tower 1 side is provided with circulating water pump 10 and dosing pump 11, and described oxidation tower 1 and all The circulating water pump 10 is arranged in the water tank 17, the water tank 17 is mechanically connected to the pH meter 12, the circulating water pump 10 enters the catalytic packed bed 7 through the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com