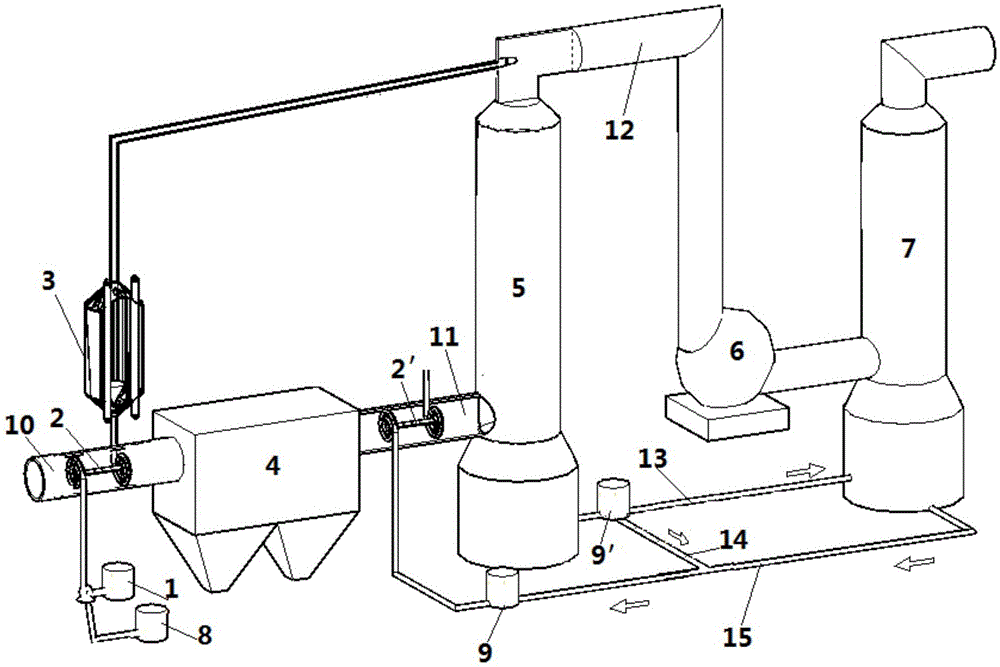

Flue gas purification device and method combining photo-catalytic oxidization and double cyclic absorption

A photocatalytic oxidation and flue gas purification technology, applied in the field of flue gas purification, can solve the problems of less control, high energy consumption, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

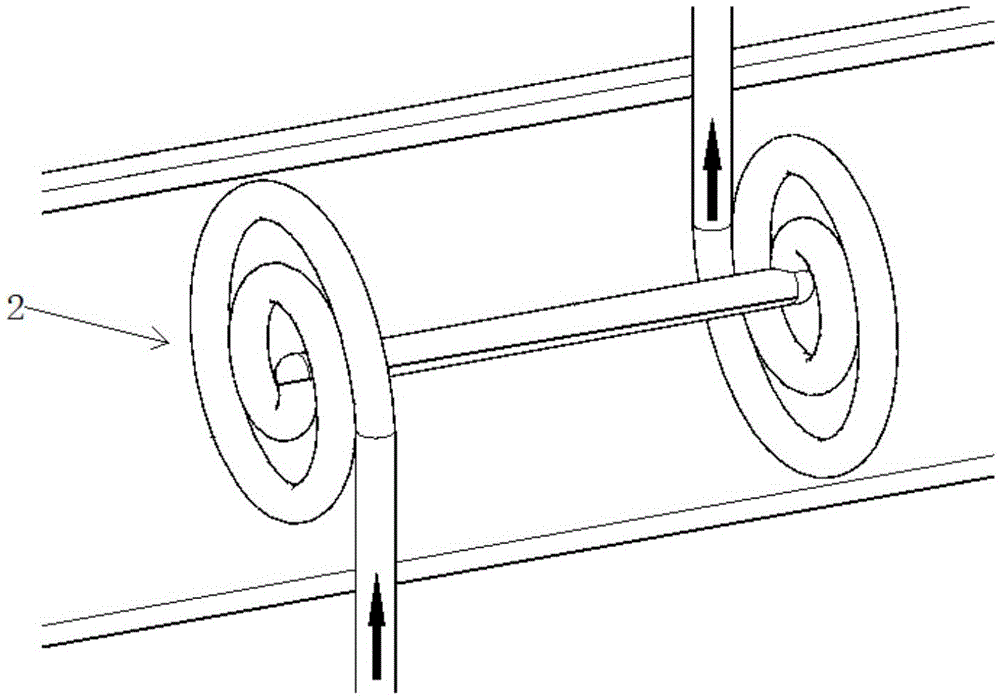

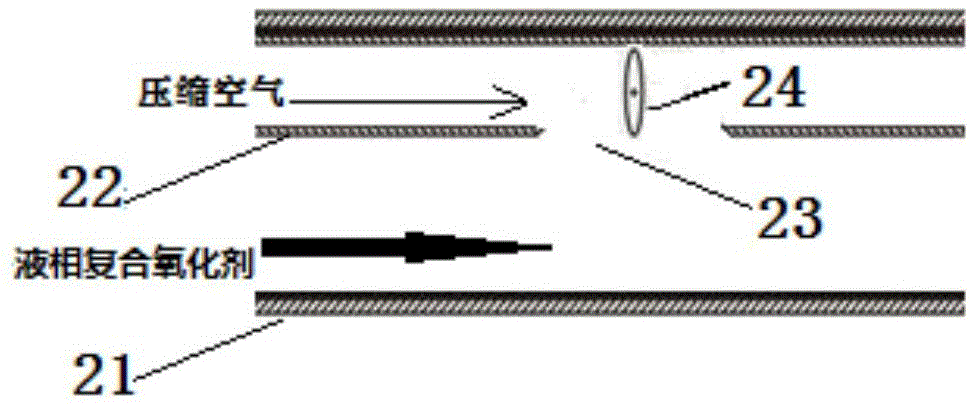

Method used

Image

Examples

Embodiment 1

[0080] The first-stage absorption liquid: the mass concentration of potassium humate is 15wt%, and the pH is 12.

[0081] The second-stage absorption liquid: the mass concentration of KOH is 3wt%, and the pH is 10.

[0082] Liquid composite oxidant: H 2 o 2 and K 2 S 2 o 8 The mass concentration ratio is 30:10, and the pH is 4.5.

[0083] The reaction conditions of the flue gas purification system with photocatalytic oxidation combined with double-cycle absorption are shown in Table 2.

[0084] Table 2

[0085]

[0086]

[0087] The flue gas is purified according to the above conditions, and it is detected that the desulfurization efficiency reaches 99%, the denitrification efficiency reaches 86%, the mercury removal efficiency reaches 91%, and the decarbonization efficiency is 46%.

Embodiment 2

[0089] The first-stage absorption liquid: the mass concentration of potassium humate is 20wt%, and the pH is 13.

[0090] The second-stage absorption liquid: the mass concentration of KOH is 1wt%, and the pH is 9.

[0091] Liquid composite oxidant: H 2 o 2 and K 2 S 2 o 8 The mass concentration ratio is 30:5, and the pH is 5.

[0092] The reaction conditions of the flue gas purification system with photocatalytic oxidation combined with double-cycle absorption are shown in Table 3.

[0093] table 3

[0094]

[0095]

[0096] The flue gas is purified according to the above conditions, and it is detected that the desulfurization efficiency reaches 98%, the denitrification efficiency reaches 85%, the mercury removal efficiency reaches 90%, and the decarbonization efficiency is 45%.

Embodiment 3

[0098] The first-stage absorption liquid: the mass concentration of potassium humate is 18wt%, and the pH is 12.5.

[0099] The second-stage absorption liquid: the mass concentration of KOH is 2wt%, and the pH is 9.

[0100] Liquid composite oxidant: H 2 o 2 and K 2 S 2 o 8 The mass concentration ratio is 20:10, and the pH is 6.

[0101] The reaction conditions of the flue gas purification system with photocatalytic oxidation combined with double-cycle absorption are shown in Table 4.

[0102] Table 4

[0103]

[0104]

[0105] The flue gas is purified according to the above conditions, and it is detected that the desulfurization efficiency reaches 98%, the denitrification efficiency reaches 88%, the mercury removal efficiency reaches 92%, and the decarbonization efficiency is 46%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com