Power semiconductor device

A technology of power semiconductor and main layer, applied in the direction of semiconductor devices, electrical components, thyristors, etc., can solve the problems of high state loss and high on-state loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

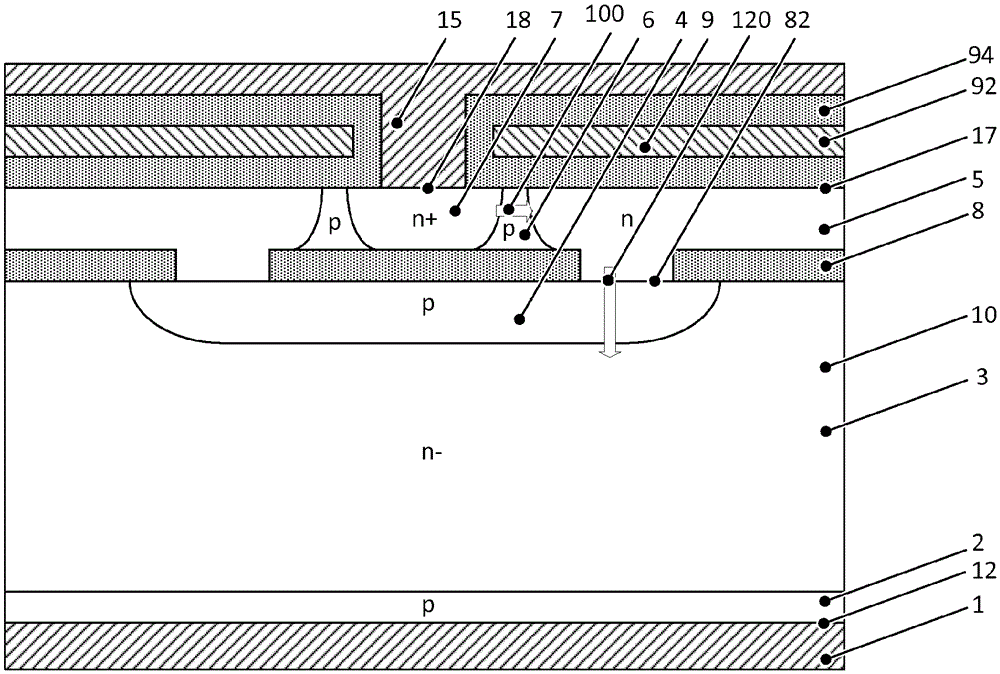

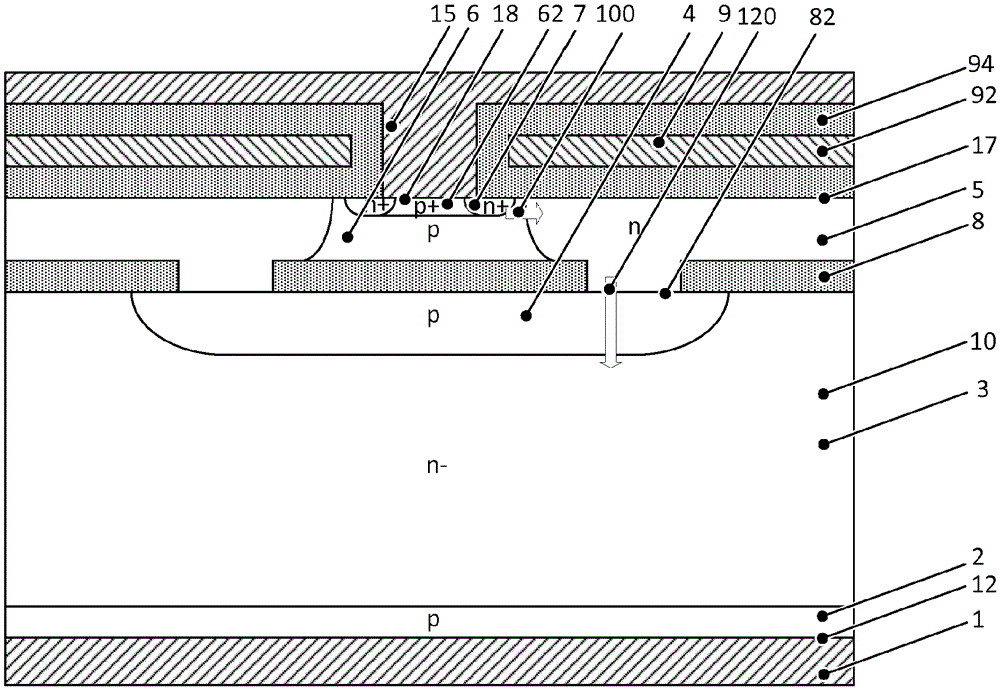

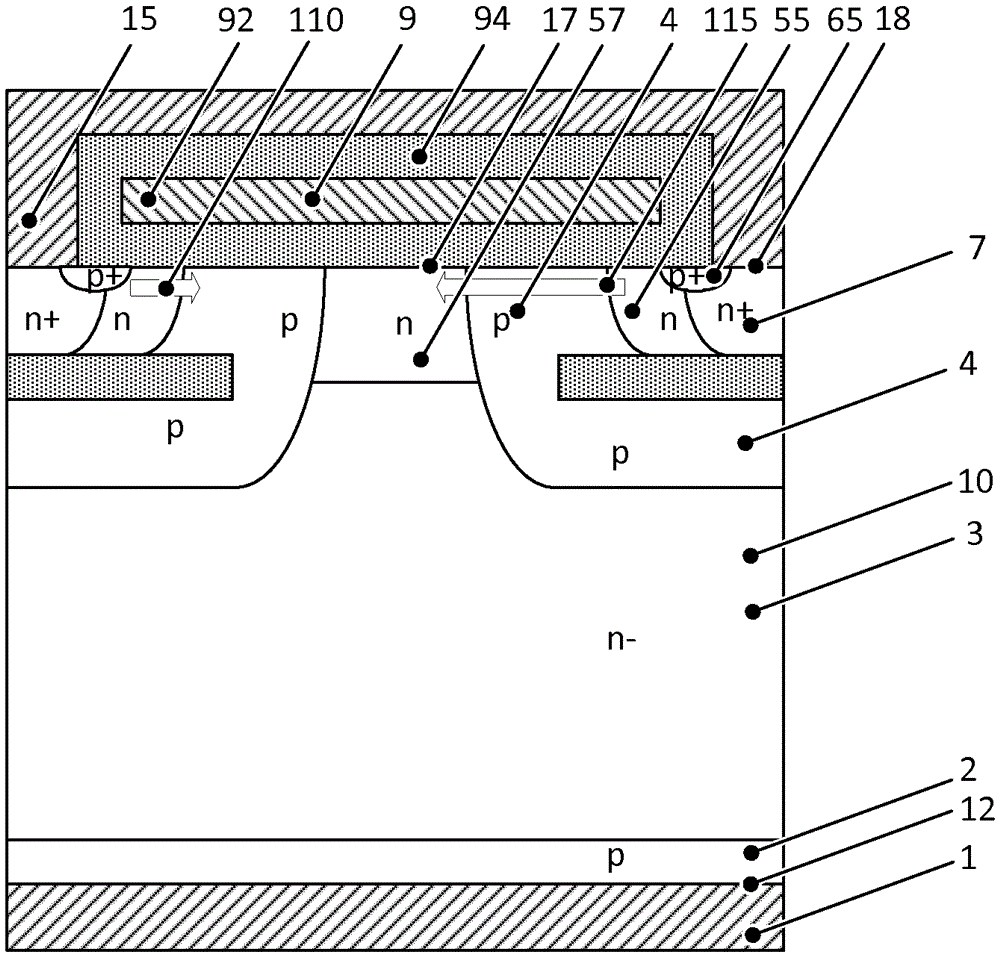

[0038] Such as figure 2 The illustrated inventive power semiconductor device having at least a four-layer structure with layers of a first conductivity type and a second conductivity type different from the first conductivity type comprises a wafer 10 on which an emitter electrode 15 is arranged on On the emitter side 17 of the wafer, and the collector electrode 1 is arranged on the collector side 12 of the wafer opposite the emitter side 17 .

[0039] The wafer comprises n and p doped layers between the collector side 12 and the emitter side 17 . The device includes in the following order:

[0040] -p-doped collector layer 2,

[0041] - a constant low (n-) doped drift layer 3,

[0042] -p-doped base layer 4,

[0043] - a first insulating layer 8 with openings (vias) 82,

[0044] - a highly n-doped emitter layer 5 having a higher maximum doping concentration than the drift layer 3, wherein the emitter layer 5 is in contact with the base layer 4 at the opening 8, and wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com