Silicone compound having a radical-polymerizable group and a method for the preparation thereof

A technology of siloxane compounds and polymerizable groups, which is applied in the fields of compounds of Group 4/14 elements of the periodic table, chemical instruments and methods, and medical preparations containing active ingredients, etc. Good handling properties, excellent oxygen permeability, and good reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0111] Add 0.1 mol of siloxane-containing amine of the following formula (I), 200 ml of hexane, and 170 g of 10% sodium carbonate water to a flask equipped with a thermometer, a dropping funnel, and a nitrogen gas introduction tube, and stir at 5° C. 1.2 mol of acryloyl chloride was added dropwise.

[0112] [chem 21]

[0113]

[0114] After the dropwise addition, stirring was continued at room temperature for 5 hours, and then the organic layer was washed with pure water. Next, 0.008 g of p-methoxyphenol (polymerization inhibitor) was added to the washed solution, and the volatile components were distilled off under reduced pressure (60°C, 5 torr) to obtain a light yellow transparent liquid at room temperature (25°C). product. use 1 As a result of identification by H-NMR measurement, it was a compound represented by the following formula (II). The yield was 96.9%.

[0115] [chem 22]

[0116]

[0117] Shown below 1 H-NMR spectrum.

[0118] 1 H-NMR (400MHz, CDCl 3 ...

Embodiment 2

[0120] The method of Example 1 was repeated except that the compound represented by the following formula (III) was used instead of the compound represented by the above formula (I), and a light yellow transparent liquid product was obtained at room temperature (25° C.).

[0121] [chem 23]

[0122]

[0123] use 1 As a result of identification by H-NMR measurement, it was a siloxane compound represented by the following formula (IV). The yield was 97.3%.

[0124] [chem 24]

[0125]

[0126] Shown below 1 H-NMR spectrum.

[0127] 1 H-NMR (400MHz, CDCl 3 ): δ0.00(s,6H), 0.07(s,36H), 0.34~0.48(m,4H), 1.49~1.67(m,4H), 3.18~3.39(m,4H), 5.62(dd,1H ), 6.32 (ddd, 1H), 6.53 (dd, 1H).

Embodiment 3

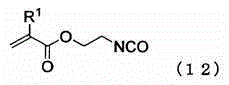

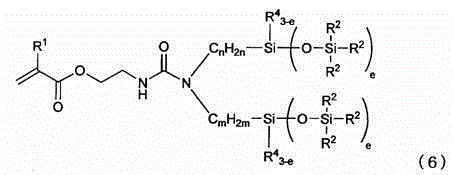

[0129] Except for using 2-acryloyloxyethyl isocyanate instead of acryloyl chloride, the method of Example 1 was repeated to obtain a pale yellow transparent liquid product at room temperature (25° C.). use 1 As a result of H-NMR measurement and identification, it was a siloxane compound represented by the following formula (V). The yield was 95.2%.

[0130] [chem 25]

[0131]

[0132] Shown below 1 H-NMR spectrum.

[0133] 1 H-NMR (400MHz, CDCl 3 ): δ0.07(s,54H), 0.34~0.45(m,4H), 1.49~1.68(m,4H), 3.08~3.20(m,4H), 3.49~3.59(m,2H), 4.18~4.28 (m, 2H), 4.72 (br, 1H), 5.82 (dd, 1H), 6.15 (ddd, 1H), 6.39 (dd, 1H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com