A centerless grinder automatic feeder

A centerless grinding machine and automatic feeding technology, which can be used in grinding machines, grinding feed motion, grinding machine parts, etc., and can solve the problems of high labor intensity, uneven feeding speed, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

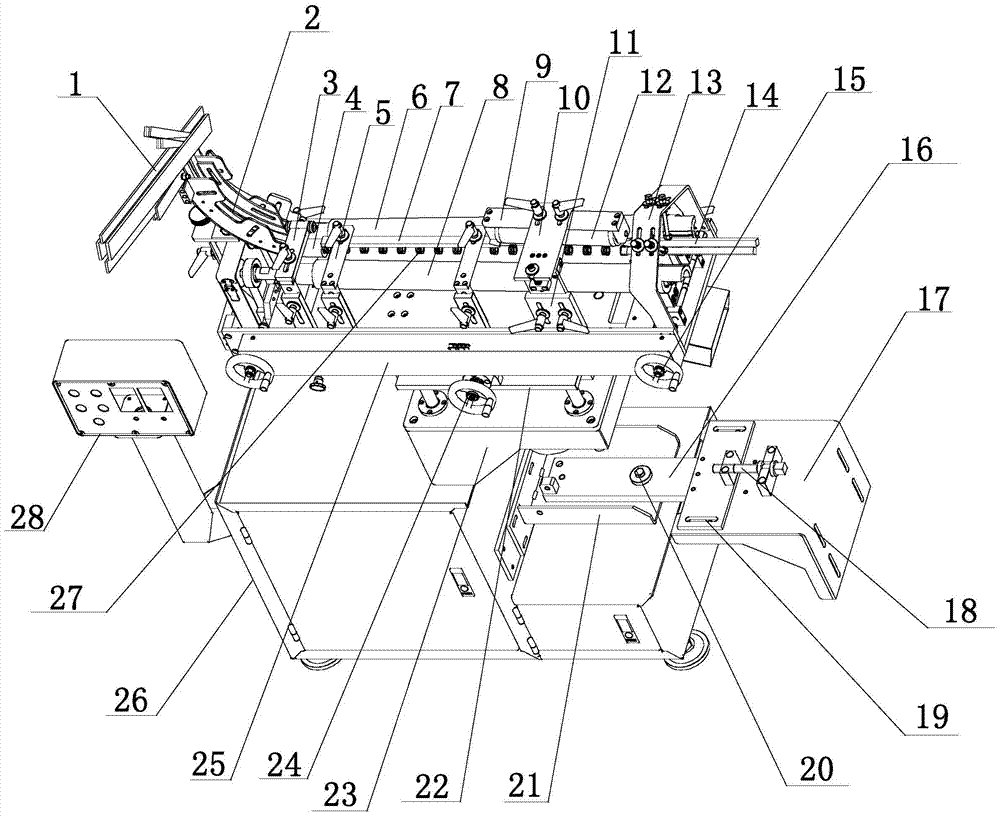

[0019] Such as Figure 1 ~ Figure 3 As shown, the present invention includes a machine base 26, an electrical control system 28, a transverse conveying device, a transverse conveying device installation mechanism, a material guide device and a connection fine-tuning mechanism, and the transverse conveying device includes a base 25, a motor 29, a first shaft roller 6, a Two shaft rollers 8, layering mechanism, guide roller mechanism and limit guiding mechanism, described first shaft roller 6 and second shaft roller 8 are all provided with the stepped shaft of the step end face toward the left, the first shaft roller 6 and The second shaft rollers 8 are arranged side by side and are separated by a certain distance to form a transverse conveying channel. The vertical planes where the axes of the first shaft rollers 6 and the second shaft rollers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com