Forming and centering method of torsion beam of pipe fittings

A technology of torsion beam and pipe fittings, applied in the field of torsion beams of pipe fittings, can solve the problems of deviation of the torsion beam of pipe fittings, deviation of tube blanks, affecting the forming accuracy of products, etc., and achieves the effect of good forming accuracy and preventing deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below, the structure and working principle of the present invention will be further described in conjunction with the accompanying drawings.

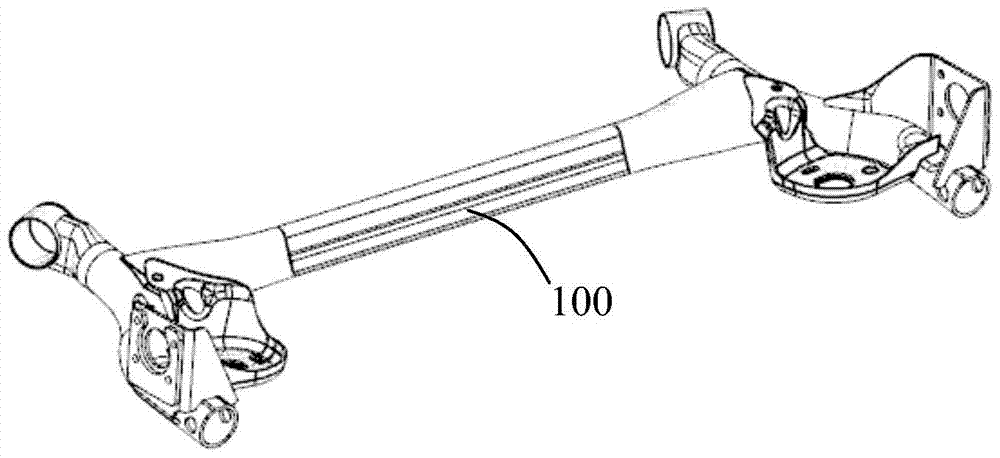

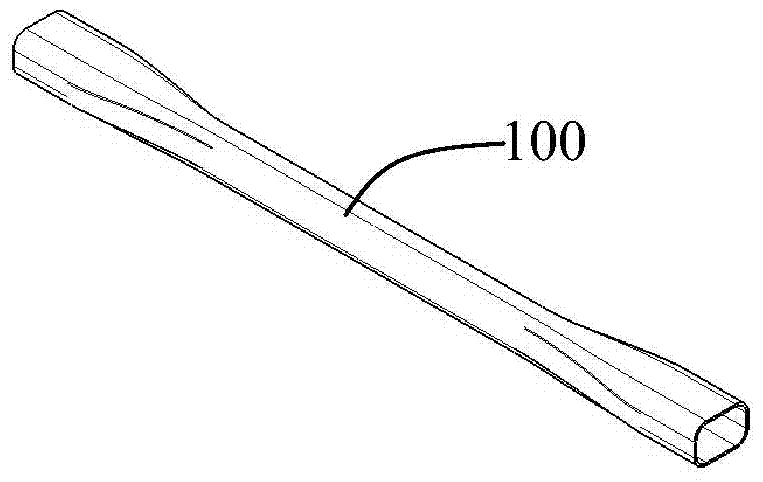

[0029] The forming and centering method of a pipe fitting torsion beam of the invention is used for forming a torsion beam made of pipe fittings.

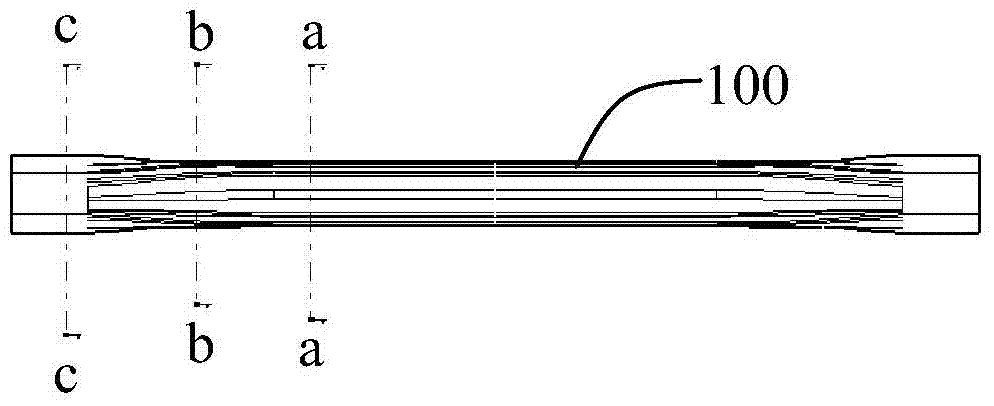

[0030] The method includes the following steps:

[0031] Step 1, preforming the tube blank, the preformed tube blank has a roughly V-shaped or U-shaped cross section.

[0032] Such as Figure 5a As shown, the tube blank 10 is a standard circular tube with a uniform thickness of the tube wall for subsequent processing and shaping.

[0033] Such as Figure 5b As shown, in this step, the tube blank 10 is preformed by the mold, so that its cross-section is roughly V-shaped, that is, it has two inclined sides that are symmetrical along the horizontal direction, and this shape is mainly convenient for subsequent positioning of the tube blank 10 , to prevent its rotation deviation.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com