Three-roller skew rolling forming method for right-angle stepped shaft

A technology of stepped shaft and skew rolling, applied in metal rolling and other directions, can solve the problems of external shape and performance difference of shaft parts, reduce the forming accuracy of shaft parts, material waste, etc. Good consistency and good forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

[0024] As shown in the figure, a three-roll skew rolling forming method for a right-angle stepped shaft includes the following specific steps:

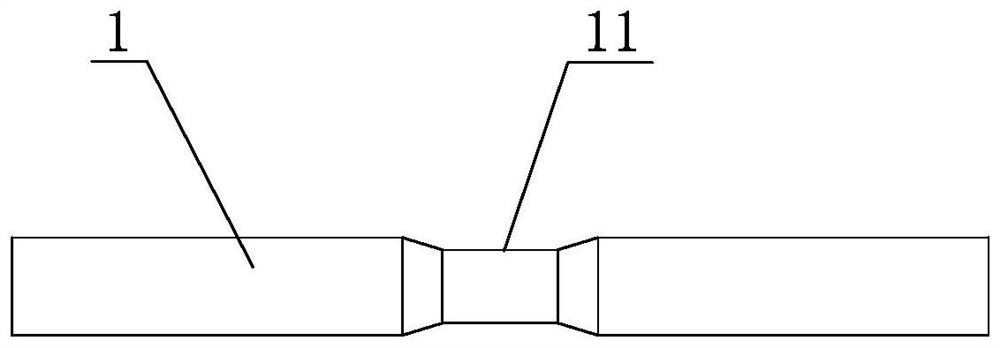

[0025] (1) Take the cylindrical billet 1 and heat it to 950℃~1250℃, then carry out cross wedge rolling on the billet 1, and roll out the annular groove section 11 in the middle of the billet 1, such as figure 1 shown;

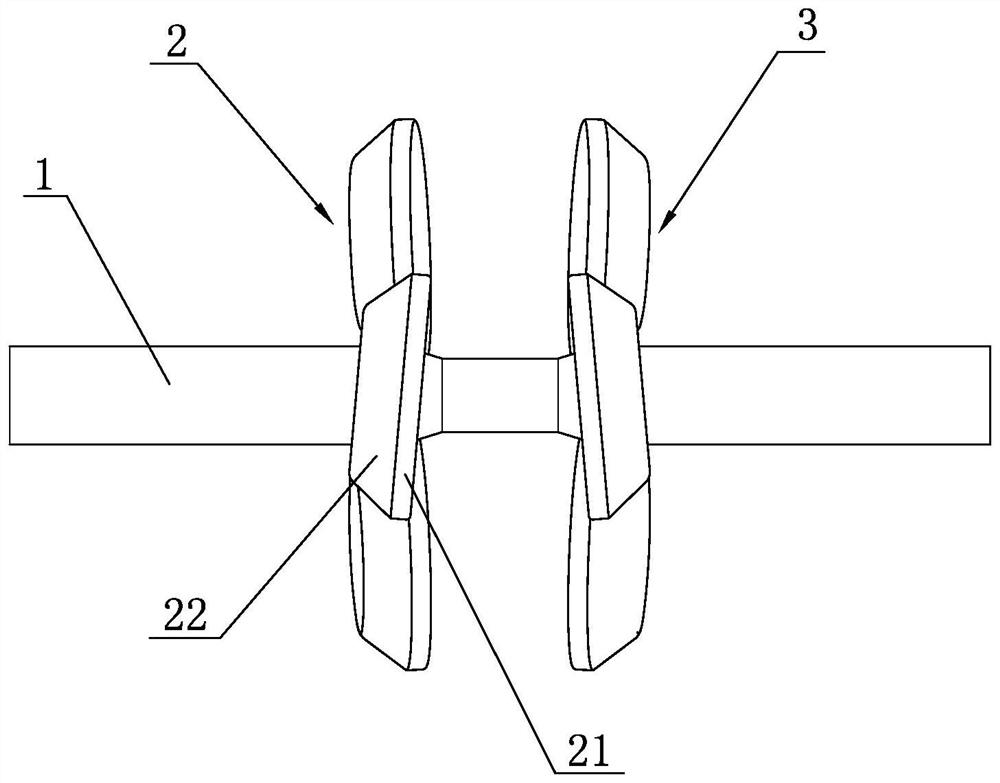

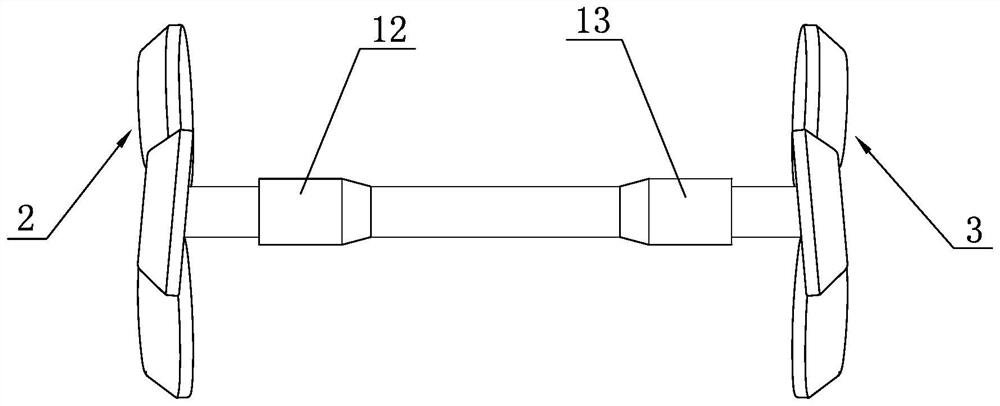

[0026] (2) Two sets of oppositely arranged skew roll groups 2 and 3 are arranged in the three-roll skew rolling mill. The skew rolls in the skew roll sets 2 and 3 are composed of a cylindrical portion 21 and a circular truncated portion 22, and two sets of skew roll groups 2 , the cylindrical portion 21 of 3 is opposite;

[0027] (3) Install the blank 1 with the groove section 11 in the above-mentioned three-roll skew rolling mill, and the initial positions of the two sets of skew r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com