Re-concentration method for hematite combined tailings

A technology of hematite and tailings, which is applied in the field of hematite comprehensive tailings re-election, can solve the problems of ecological environment hazards, unreasonable utilization of mineral resources, waste of resources, etc., and achieve effective recovery, significant economic benefits, and reduce The effect of waste and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

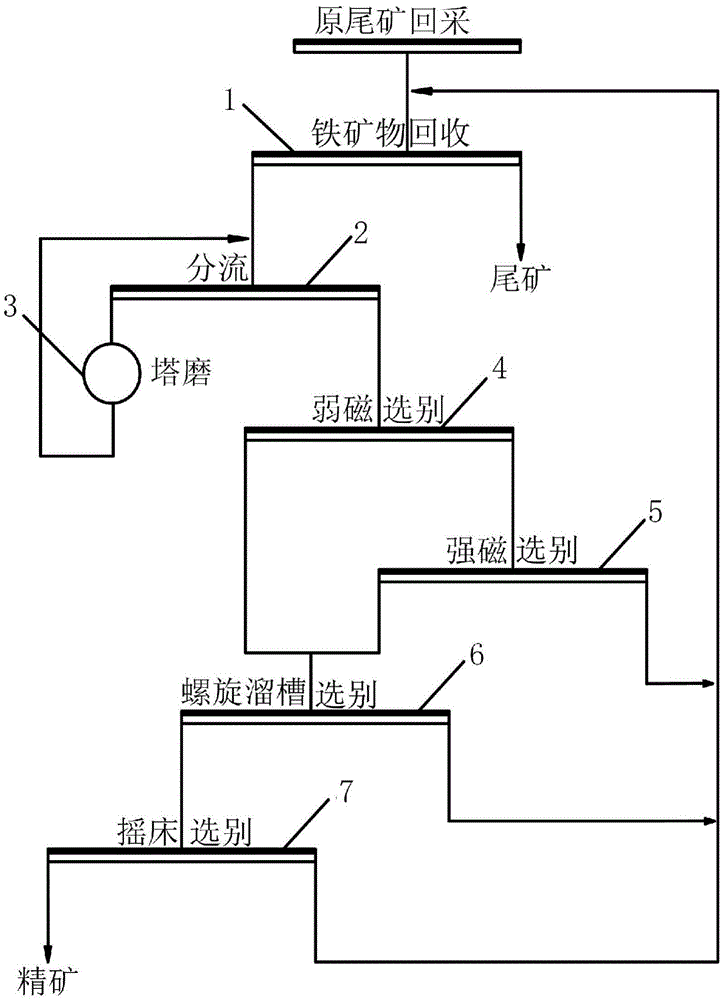

[0028] Such as figure 1 As shown, the hematite comprehensive tailings re-election method in the present embodiment comprises the following steps:

[0029] (1) Send the original tailings of TFe12% to tailings recycling machine 1 after the water mining process to reclaim the iron minerals in the original tailings;

[0030] (2) The iron ore reclaimed in step (1) is fed into cyclone 2, and the underflow of cyclone 2 is fed into tower mill 3 for ore grinding, and the ore discharge of tower mill 3 is returned to cyclone 2 to form a closed circuit mill mine;

[0031] (3) The tailings fineness of the hydrocyclone 2 is less than 0.037mm, and the overflow of 95% of the total material mass is given to the weak magnetic separation equipment 4 for weak magnetic separation. The magnetic field strength is 1000Oe, and the weak magnetic is obtained. Tailings and weakly magnetic concentrates;

[0032] (4) the weak magnetic tailings that step (3) weak magnetic separation obtains is given into...

Embodiment 2

[0038] Such as figure 1 As shown, the hematite comprehensive tailings re-election method in the present embodiment comprises the following steps:

[0039] (1) Send the original tailings of TFe15% to the tailings recovery machine 1 after the water mining process to reclaim the iron minerals in the original tailings;

[0040] (2) The iron ore reclaimed in step (1) is fed into cyclone 2, and the underflow of cyclone 2 is fed into tower mill 3 for ore grinding, and the ore discharge of tower mill 3 is returned to cyclone 2 to form a closed circuit mill mine;

[0041] (3) The tailings fineness of the hydrocyclone 2 is less than 0.037mm, and the overflow of 93% of the total material mass is given to the weak magnetic separation equipment 4 for weak magnetic separation. The magnetic field strength is 800Oe, and the weak magnetic is obtained. Tailings and weakly magnetic concentrates;

[0042] (4) the weak magnetic tailings that step (3) weak magnetic separation obtains is given in...

Embodiment 3

[0048] Such as figure 1 As shown, the hematite comprehensive tailings re-election method in the present embodiment comprises the following steps:

[0049] (1) Send the original tailings of TFe10% to the tailings recovery machine 1 after the water mining process to reclaim the iron minerals in the original tailings;

[0050] (2) The iron ore reclaimed in step (1) is fed into cyclone 2, and the underflow of cyclone 2 is fed into tower mill 3 for ore grinding, and the ore discharge of tower mill 3 is returned to cyclone 2 to form a closed circuit mill mine;

[0051] (3) The tailings fineness of the hydrocyclone 2 is less than 0.037mm, and the overflow of 98% of the total material mass is given to the weak magnetic separation equipment 4 for weak magnetic separation. The magnetic field strength is 1200Oe, and the weak magnetic is obtained. Tailings and weakly magnetic concentrates;

[0052] (4) the weak magnetic tailings that step (3) weak magnetic separation obtains is given i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com