Process of making liquid cleaning composition

一种清洁组合物、液体组合物的技术,应用在洗涤剂组合物、洗涤剂混合物组合物的制备、表面活性洗涤剂组合物等方向,能够解决很难同时实现、制剂范围不灵活等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

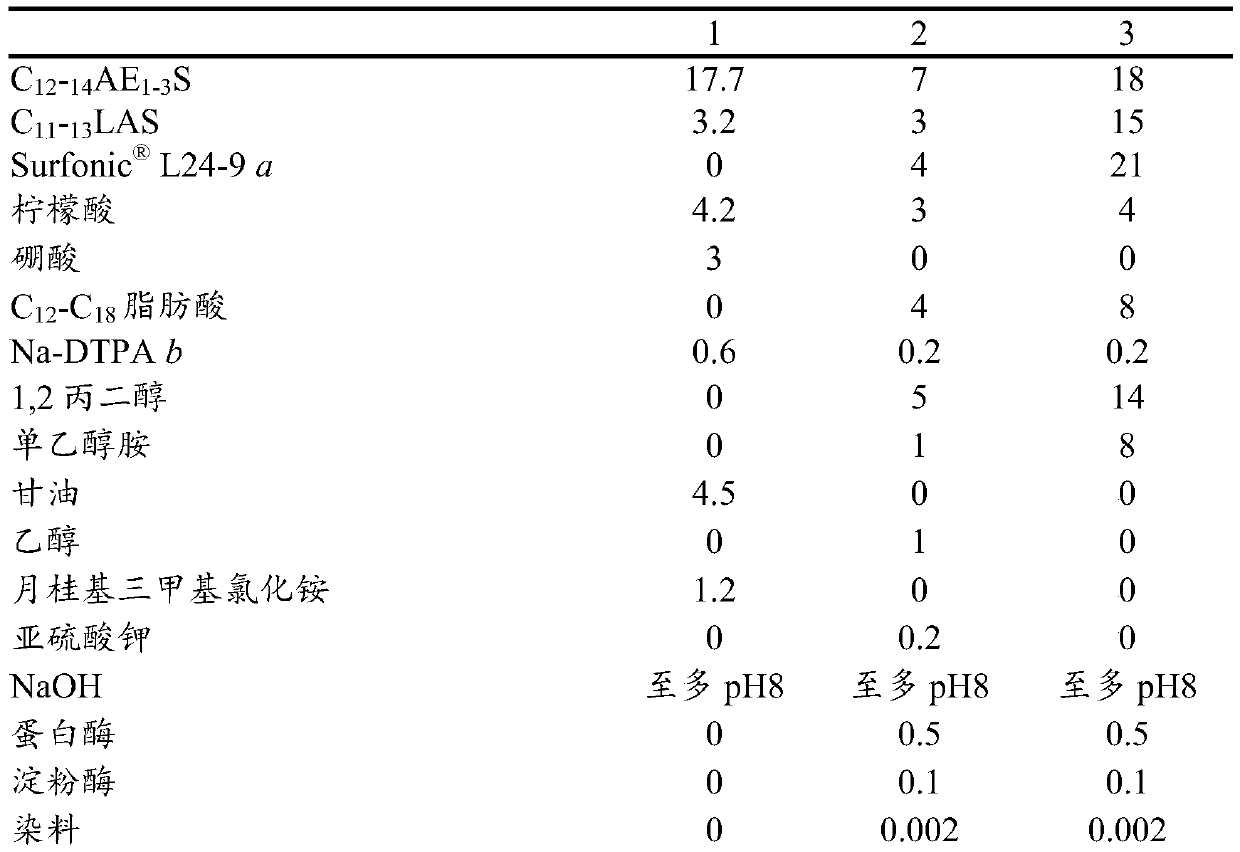

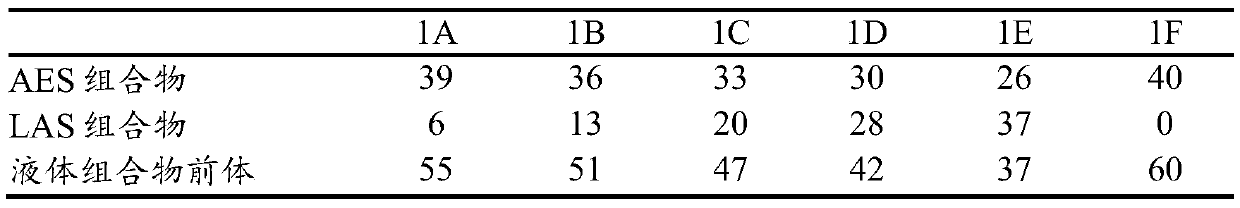

[0110] The examples herein are intended to illustrate the invention, but not to limit or otherwise define the scope of the invention. Examples 1-3 are liquid laundry detergent composition examples according to the present invention, Examples 1A-1E are process examples according to the present invention, and Examples 1F-1H are process comparative examples.

[0111] Examples 1-3: Formulation of Liquid Laundry Detergent Compositions

[0112] The following liquid laundry detergent compositions were prepared as shown in Table 1 containing the listed ingredients in the listed proportions (weight %).

[0113] Table 1 :

[0114]

[0115]

[0116] a L24-9 is C ethoxylated with 9 moles of ethylene oxide 12-14 Alcohol, which was purchased from Huntsman as a nonionic surfactant

[0117] b diethylenetriaminepentaacetic acid pentasodium salt as a chelating agent

example 1A

[0118] Example 1A: Process for preparing the liquid laundry detergent composition of Example 1 according to the present invention

[0119] Method Example 1A includes the steps of:

[0120] a) providing a recirculating batch processor, wherein the recirculating batch processor comprises a batch container and a recirculation loop in fluid communication with the batch container, wherein the batch container has a volume of 80 liters and the loop has a volume of about 0.0005 m 2 cross-sectional area;

[0121] b) Add citric acid, boric acid, Na-DTPA, glycerin, lauryltrimethylammonium chloride, NaOH, and water to a batch vessel to form a liquid composition precursor, and place the liquid composition precursor in a loop as 3.7kg / min flow rate for recirculation;

[0122] c) replace C 12-14 AE 1-3 S is dispensed into the circuit at a first rate of 1.7 kg / min at the first circuit location for about 8.3 minutes while the liquid composition precursor is recirculated, wherein C 12- ...

example 1B

[0128] Example 1B: Process for preparing the liquid laundry detergent composition of Example 1 according to the present invention

[0129] Process Example 1B is the same as Process Example 1A, except that the liquid composition precursor flows in the recirculation loop at a flow rate of 3.4 kg / min, and in step c) the C 12-14 AE 1- 3 S is dispensed into the circuit for about 8.9 minutes at a first rate of 1.6 kg / min, and in step d) C 11-13 LAS was dispensed into the circuit for about 3.1 minutes at a second rate of 0.9 kg / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com