Water-absorbing resin manufacturing method, water-absorbing resin, water-absorbing agent, absorbent article

A manufacturing method and technology of water absorption, applied in the direction of absorbent pads, bandages, medical science, etc., can solve the problems of increasing, low diffusivity, hindering the diffusibility of absorbed liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

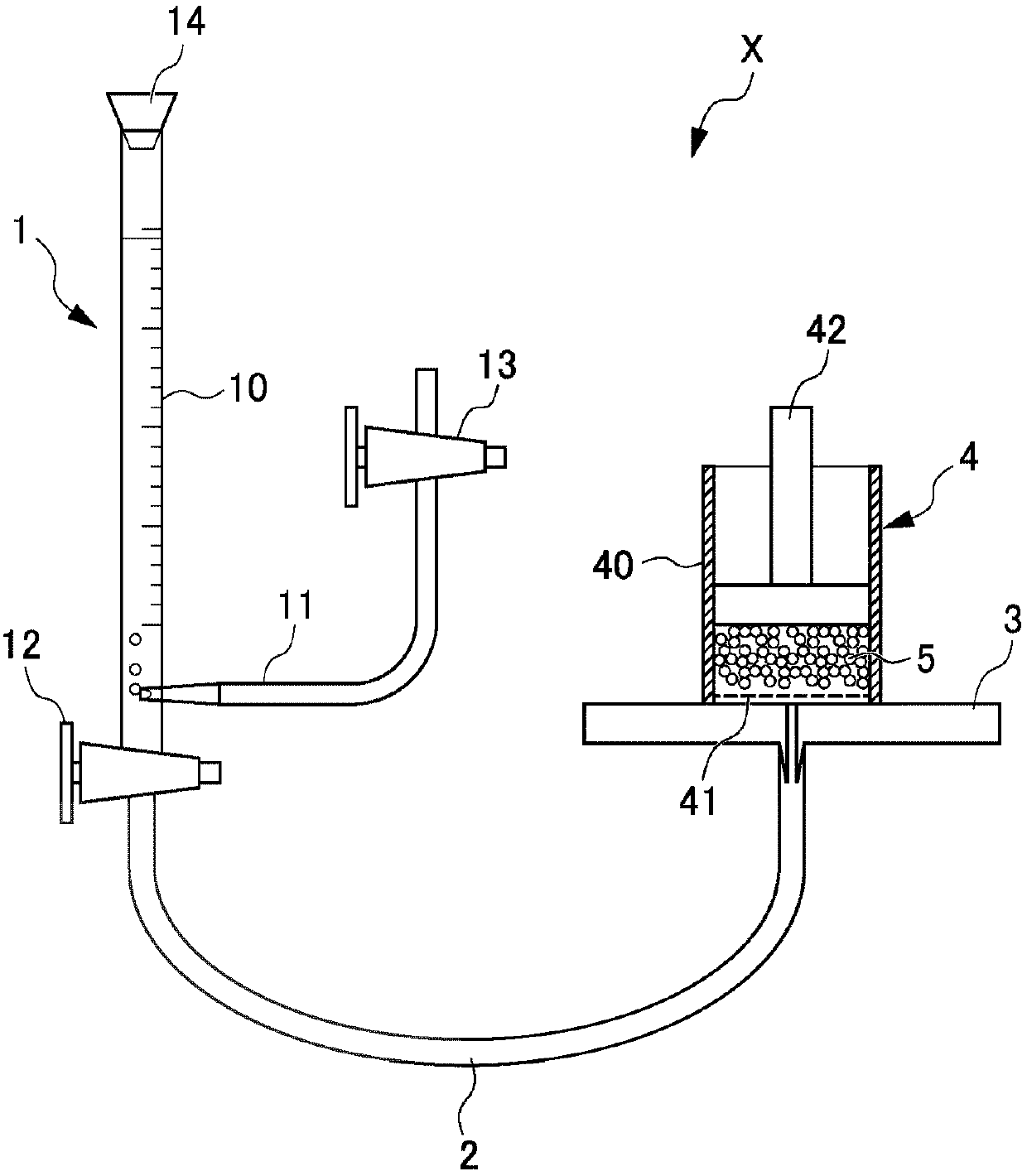

[0150]In Example 1, a round-bottomed cylindrical detachable flask with an inner diameter of 110 mm and a volume of 2 L was prepared. The flask was provided with a reflux condenser, a dropping funnel, a nitrogen gas introduction pipe, and a mixer with 4 impellers of 50 mm in diameter in two stages. Stirring impeller with inclined paddle impeller. In this flask, 300 g of n-heptane was added as a hydrocarbon dispersion medium, 0.74 g of sucrose stearate (Mitsubishi Chemical Foods Co., Ltd., RyotoSugarEster S-370) of HLB3 was added as a surfactant, and horseradish as a polymer dispersant. 0.74 g of anhydride-modified ethylene-propylene copolymer (Mitsui Chemicals, Inc., High Wax 1105A) was heated up to 80° C. while stirring to dissolve the surfactant, and then cooled to 50° C.

[0151] On the other hand, 92 g (1.02 moles) of an 80 mass % acrylic acid aqueous solution was placed in a 500-mL Erlenmeyer flask, and while cooling from the outside, 102.2 g of a 30 mass % sodium hydroxid...

Embodiment 2

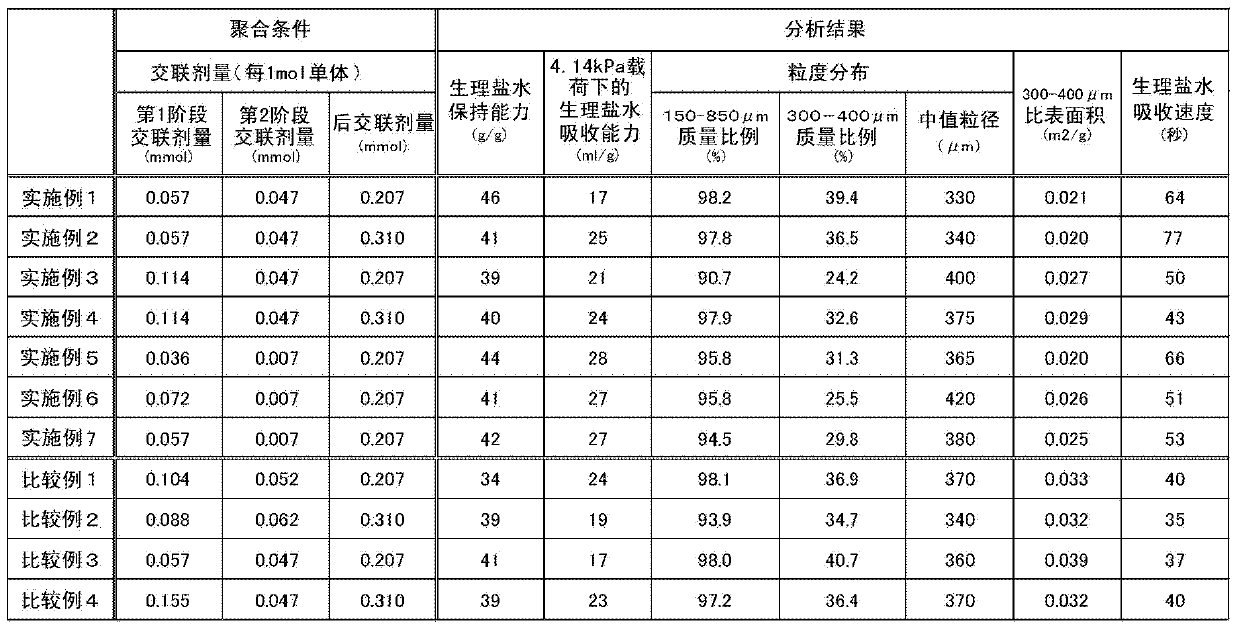

[0158] In Example 2, except that the 2% aqueous solution of ethylene glycol diglycidyl ether added as a post-crosslinking agent was changed to 6.62 g (0.761 micromole), the same operation as Example 1 was carried out to obtain 232.9 g of water-absorbent resin in the form of secondary particles in which spherical primary particles were aggregated. The water-absorbent resin thus obtained was evaluated according to the above-mentioned various test methods.

[0159] In addition, in the obtained water-absorbent resin, the mass ratio of the particles of 150 to 850 μm to the entire water-absorbent resin was 97.8% by mass, and the mass ratio of the particles of 300 to 400 μm to the entire water-absorbent resin was 97.8% by mass. The proportion is 36.5% by mass.

Embodiment 3

[0161] In Example 3, the ethylene glycol diglycidyl ether as an internal crosslinking agent added to the monomer in the first stage was changed to 0.0202 g (0.116 micromole), and the stirring speed of the stirrer was set at 500 rpm to perform the first step. Except for the stepwise polymerization, the same operation as in Example 1 was carried out to obtain 231.0 g of a water-absorbent resin having a form of secondary particles in which spherical primary particles were aggregated. The water-absorbent resin thus obtained was evaluated according to the above-mentioned various test methods.

[0162] In addition, in the obtained water-absorbent resin, the mass ratio of the particles of 150 to 850 μm to the entire water-absorbent resin was 90.7% by mass, and the mass ratio of the particles of 300 to 400 μm to the entire water-absorbent resin was 90.7% by mass. The proportion is 24.2% by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com