Outer casing pipe constraint folding steel plate energy consumption support

An energy-dissipating support and outer casing technology, which is applied to building components, shock-proof and other directions, can solve the problems that the energy-dissipation performance of the support cannot be accurately controlled, the position of the yield point of the core board cannot be controlled, and the energy-dissipation capacity of the core board cannot be exerted. The effect of improving hysteretic energy dissipation performance, increasing hysteretic energy dissipation capacity, and optimizing energy dissipation mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

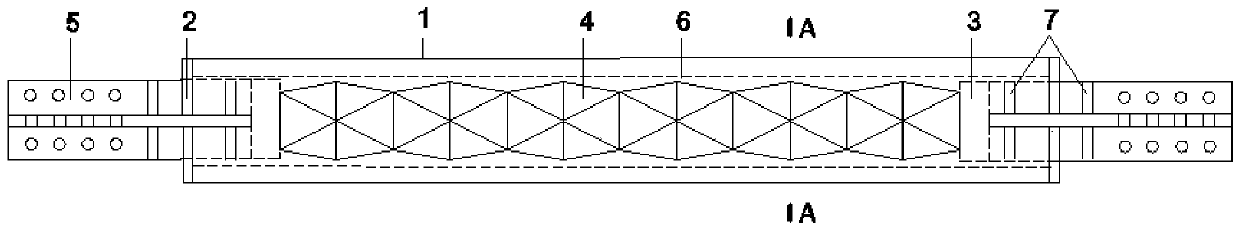

[0039] as follows figure 1 As shown in Fig. 6, the present invention is composed of seven parts: outer casing 1, outer casing sealing plate 2, end pressure plate 3, core barrel 4, cross gusset plate 5, non-adhesive material 6, and stiffener 7. The core barrel 4 is stamped from a steel plate to form different simple geometric figures, and then welded to form a cylindrical shape. As shown in FIG. 6 , in this embodiment, the geometric figures on the core barrel 4 are combinations of isosceles triangles. Figure 7 It is the crease style in this embodiment, where the dotted line is the dent, and then the two ends can be welded. Such as figure 2 As shown, the end pressure plate 3 is connected to the core barrel 4, and the end pressure plate 3 is welded to the four sides of the core barrel 4 mouth, and the size of the end pressure plate 3 is the same as that of the core barrel 4 mouth. The other side of the end pressure bearing plate 3 is welded to the cross gusset plate 5, the c...

Embodiment 2

[0041] This embodiment is the same as the rest of Embodiment 1, except that the round tube of the outer sleeve 1 is replaced by a square tube to provide constraints.

[0042] In order to express the spatial structure of the sub-unit more clearly, a space Cartesian coordinate system is established to describe the coordinates of each node, such as Figure 8 As shown, the coordinate origin O is the center of the subunit, the X-axis is the straight line where the diagonal line FH of the quadrilateral EFGH is located, the positive direction is from F to H, and the Z-axis is the straight line where the other diagonal line EG of the quadrilateral is located. E points to G as the positive direction, and the straight line passing through the point O and perpendicular to the X-axis and Z-axis is used as the Y-axis, and the positive direction is from the plane ABCD to the plane IJKL.

[0043] The size of the energy dissipation unit should meet the following conditions (θ is the dihedral ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com