Weaving method for positive and negative twisting nylon elastic double-layer cloth

A technology of positive and negative twist and nylon, which is applied in the weaving field of positive and negative twist nylon elastic double-layer fabrics, which can solve the problems of lightness, increased fabric thickness, single pattern, etc., and achieve the effect of simple process, low weaving difficulty and low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

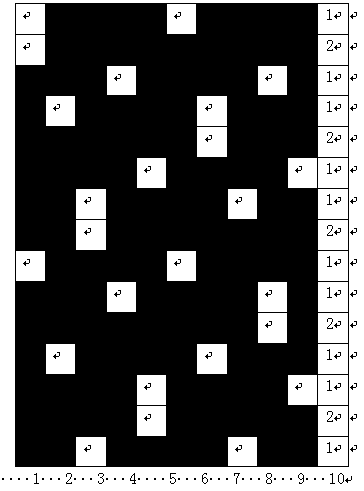

Image

Examples

Embodiment Construction

[0019] In the embodiment shown in the present invention, the weaving method of positive and negative twisted nylon elastic double-layer cloth has two kinds of fabric warps, one is JC40 (tight) (Z), and the other is JC40 (tight) (S ); the weft yarns mentioned are N140 (40D) and C8 (70D) (N: stands for nylon), the warp and weft density of the fabric is 168×105 threads / inch, and the cloth width is 80". Yarn, sizing in the first size tank and the second size tank (double size tank) for easy distinction during sizing; red pigment is added to the first size tank, no pigment is added to the second size tank, and it is worn continuously for 5 Root positive twist yarn, then wear 5 reverse twist yarns, the difference of reflection caused by different twist directions forms patterns, and dark stripes are formed after desizing; the weaving method of the present invention comprises the following method steps:

[0020] (1) Winding process: Murata automatic winding machine is used to wind th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com