A kind of sheep shearing processing method and sheep shearing processed by the method

A processing method and sheep shearing technology, applied in the field of fur processing, can solve the problems of human health hazards, unfavorable environmental protection, etc., and achieve the effects of improving quality, reducing damage and improving economic value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

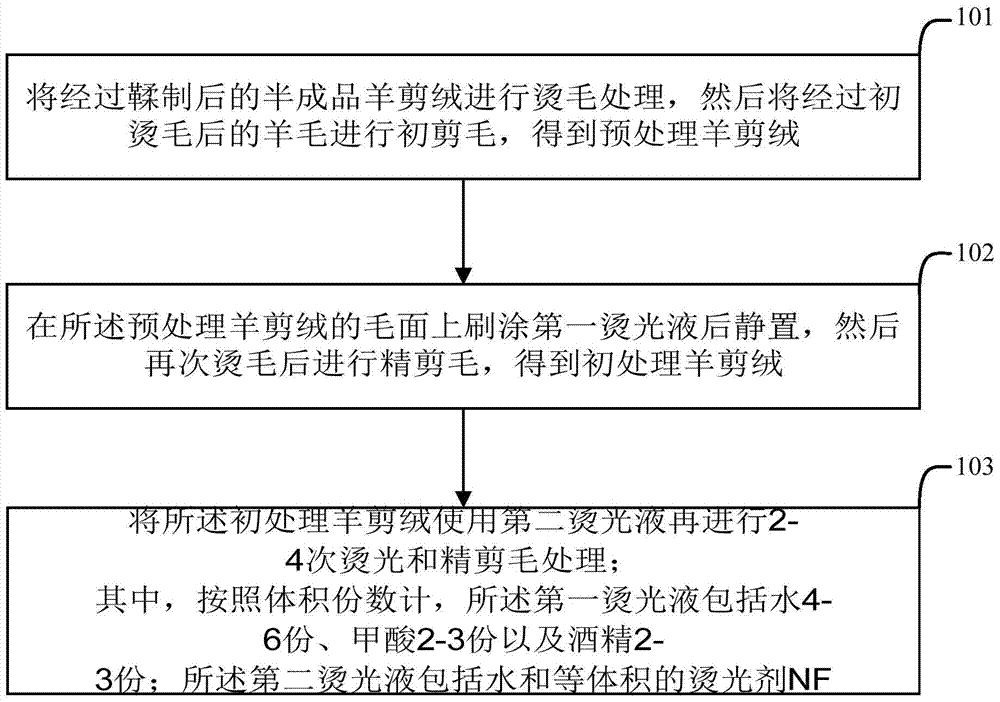

[0058] The processing method of the sheep shearing provided by the present embodiment comprises the steps:

[0059] S11: Select tanned semi-finished sheep shearling fur, adjust the temperature of the scalding machine to 160°C for scalding, and then use the primary shearing machine to cut the wool to the required length to obtain pretreated sheep shearling;

[0060] S12: Prepare the first scalding solution (mixed uniformly in the proportion of 500 milliliters of water, 300 milliliters of formic acid, and 300 milliliters of alcohol), apply the first scalding solution evenly on the wool surface of the pretreated sheep shearling, and let it stand for a while. Leave it for 15 minutes to allow the hair follicle fibers to fully absorb the chemical; then adjust the temperature of the scalding machine to 180°C, and then scald the skin that has been brushed with the first scalding liquid and rested, and then use a fine shearing machine as required Carry out shearing treatment to obtain ...

Embodiment 2

[0064] The processing method of the sheep shearing provided by the present embodiment comprises the steps:

[0065] S21: Select tanned semi-finished sheep shearing fur, adjust the temperature of the scalding machine to 170°C for scalding, and then use the primary shearing machine to cut the wool to the required length to obtain pretreated sheep shearing;

[0066] S22: Prepare the first scalding solution (mixed uniformly in the proportion of 500 milliliters of water, 300 milliliters of formic acid, and 300 milliliters of alcohol), apply the first scalding solution evenly on the wool surface of the pretreated sheep shearling, and let it stand Leave it for 25 minutes to allow the hair follicle fibers to fully absorb the chemical; then adjust the temperature of the scalding machine to 190°C, and then scald the skin that has been brushed with the first scalding liquid and rested, and then use a fine shearing machine as required Carry out shearing treatment to obtain primary treated...

Embodiment 3

[0070] The processing method of the sheep shearing provided by the present embodiment comprises the steps:

[0071] S31: Select tanned semi-finished sheep shearling fur, adjust the temperature of the scalding machine to 180°C for scalding, and then use the primary shearing machine to cut the wool to the required length to obtain pretreated sheep shearling;

[0072] S32: Prepare the first scalding solution (mixed uniformly in the proportion of 500 milliliters of water, 300 milliliters of formic acid, and 300 milliliters of alcohol), apply the first scalding solution evenly on the wool surface of the pretreated sheep shearling, and let it sit for a while. Leave it for 30 minutes to allow the hair follicle fibers to fully absorb the chemical; then adjust the temperature of the scalding machine to 200°C, and then scald the skin that has been brushed with the first scalding liquid and rested, and then use a fine shearing machine as required Carry out shearing treatment to obtain pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com