Medium-temperature modified crack pouring adhesive and preparation method thereof

A technology of joint glue and medium temperature, applied in the direction of adhesive, adhesive type, asphalt material adhesive, etc., can solve the problems of operating personnel and environmental hazards, poor performance, affecting traffic speed, etc., to meet the needs of road maintenance , wide construction temperature range and extended construction days

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

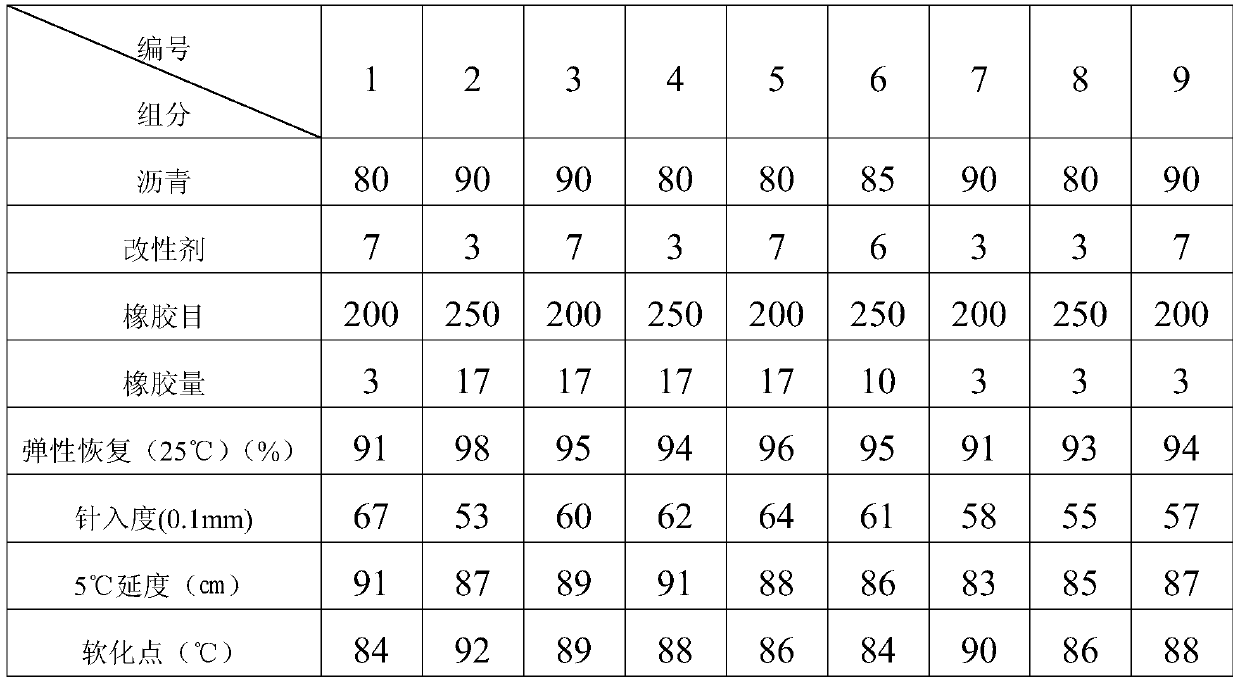

[0031] The equipment and process of the present invention will be further described in detail below in conjunction with specific examples.

[0032] The present invention designs a formula and preparation method of a medium-temperature modified caulking glue, which can reduce the conventional construction time of the caulking glue from 3 to 4 hours to 1 to 2 hours, effectively improves the construction efficiency, and saves a lot of time. time and human, material and financial resources.

[0033] The medium-temperature modified joint-filling adhesive consists of the following components in parts by mass: 80-90 parts of base asphalt, 3-7 parts of joint-filling adhesive modifier, and 3-17 parts of rubber powder.

[0034] The base asphalt is high-solid-content modified medium-temperature asphalt, which consists of the following components in parts by mass: 75-82 parts of base petroleum asphalt: 3-7 parts of medium-temperature modifier, and 11-22 parts of water.

[0035] Described...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com