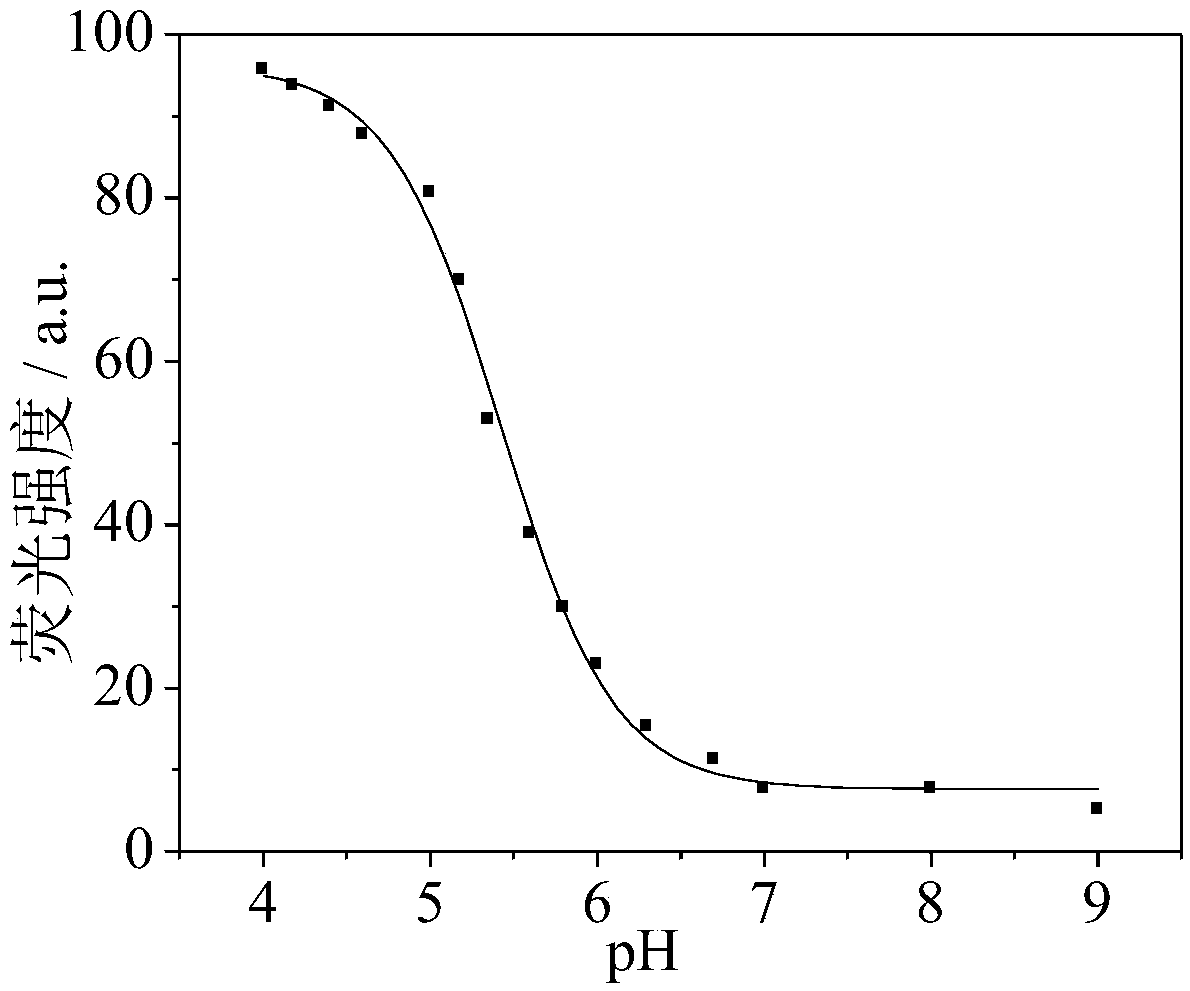

Macromolecular pH fluorescent probe for cotton transfer printing and dyeing and preparation method and application thereof

A transfer printing and dyeing, fluorescent probe technology, applied in the direction of transfer printing, dyeing, fluorescence/phosphorescence, etc., can solve the problem of difficult to judge the end point of reactive ink and fabric, and achieve the effect of accurate reaction end point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] A method for preparing a polymer pH fluorescent probe for cotton transfer printing and dyeing, comprising the following steps:

[0025] 1), Rhodamine B is reacted with hydrazine hydrate to obtain rhodamine lactam:

[0026] Add rhodamine B (2.4g, 5.01mmol) and 40mL of absolute ethanol in a 100mL round bottom flask, then slowly add 7mL of 85% hydrazine hydrate (excessive) dropwise to the round bottom flask, and start at room temperature Stir. After the dropwise addition, the reaction solution was heated to reflux at 80° C. for 2 h. During the reflux process, the solution gradually changed from dark purple to clear and transparent light orange. After the solution was cooled, the solvent ethanol was distilled off. Then add about 40mL of 1mol / L HCl to the solid to dissolve into a red transparent liquid, then slowly add 1mol / L NaOH solution (about 50mL) dropwise to the solution, and keep stirring to adjust the pH to 9-10, during which the solution continuously precipitates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com