Method for producing high-grade zircon sand

A zircon sand, high-grade technology, applied in chemical instruments and methods, zirconium compounds, inorganic chemistry, etc., can solve the problem of high production costs, difficult environmental pollution control, and product quality that cannot meet the quality standards of high-purity zirconium oxychloride, etc. problems, to achieve the effect of high product quality, small footprint, and large operating load flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

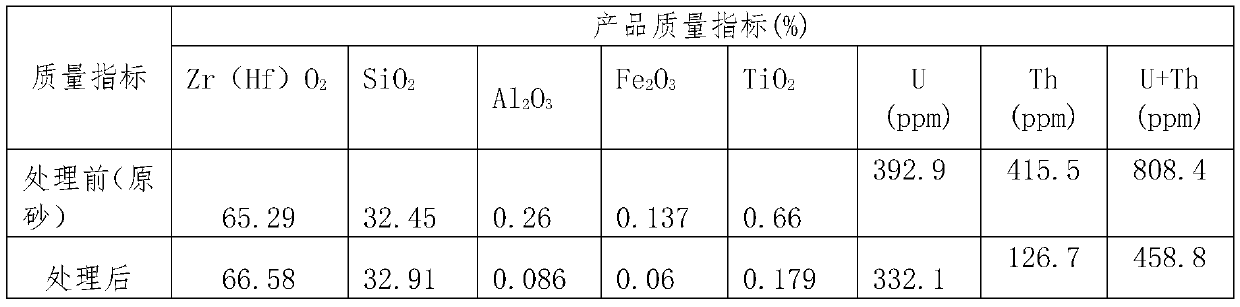

Image

Examples

Embodiment 1

[0074] Method for producing high-grade zircon sand by submerging and burning zircon sand

[0075] 1. First add a certain concentration and a certain amount of fresh sulfuric acid liquid, recovered acid liquid and a certain amount of water into the acid mixing tank, mix to obtain 70% sulfuric acid, and then pump 70% sulfuric acid into the submerged combustion reactor Then add zircon sand, the liquid-solid ratio is 0.5:1, and then pass through natural gas combustion and heating to obtain the flue gas obtained after high-temperature combustion at 800-1000 ° C. The high-temperature flue gas passes through heat transfer with sulfuric acid in the reactor, and then Heat the zircon sand and sulfuric acid in the kettle, and adjust the temperature of the sulfuric acid by adjusting the intake of high-temperature combustion gas. According to the process requirements, first heat the sulfuric acid to 240°C-260°C, keep it warm for 2 hours, then heat it to 260°C-320°C, and keep it warm for 2 ...

Embodiment 2

[0097] Method for producing high-purity zirconium oxychloride

[0098] 1. Chlorination reaction

[0099] The raw material zircon sand, calcined petroleum coke and silicon carbide are added to the mixer according to the mass ratio of zircon sand: calcined coke: silicon carbide = 1:0.22:0.34, and the materials are mixed, and then added to the front of the furnace The silo is continuously fed into the chlorination furnace through a screw conveyor.

[0100] Chlorine gas produced by electrolysis of hydrochloric acid is fed into the bottom of the chlorination furnace, and the weight of the feed is zircon sand: chlorine gas = 1: 2.78, so that chlorine gas enters the reaction section through the distributor to react with raw materials, and the reaction temperature is controlled at 1170 ° C, and the furnace pressure is controlled. Within 3000Pa, at the same time determine the slag removal time of the chlorination furnace according to the furnace pressure, control the chlorine gas flow...

Embodiment 3

[0138] After the reaction in the reaction kettle in Example 1, the zircon sand is stirred and washed, filtered by a belt filter, and the filtered mother liquor is mixed with the primary mother liquor and the washing liquid for washing crystals in Example 2 and introduced into the mother liquor evaporator, and the mother liquor is evaporated by steam heating Evaporate the mother liquor, control the heating vapor pressure to 0.3-0.5MPa, the secondary pressure of the evaporator is at 0.2MPa-0.3MPa, evaporate to the zirconium dioxide concentration at 180-200g / l, and then follow the method described in the above-mentioned embodiment 2 Carry out crystallization, filtration, washing, re-dissolving the obtained crystals, evaporate and crystallize together with the solid hydrolyzate, filter, wash, and separate to obtain high-purity zirconium oxychloride products) to obtain zirconium oxychloride with a direct crystallization rate of more than 90% crystals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com