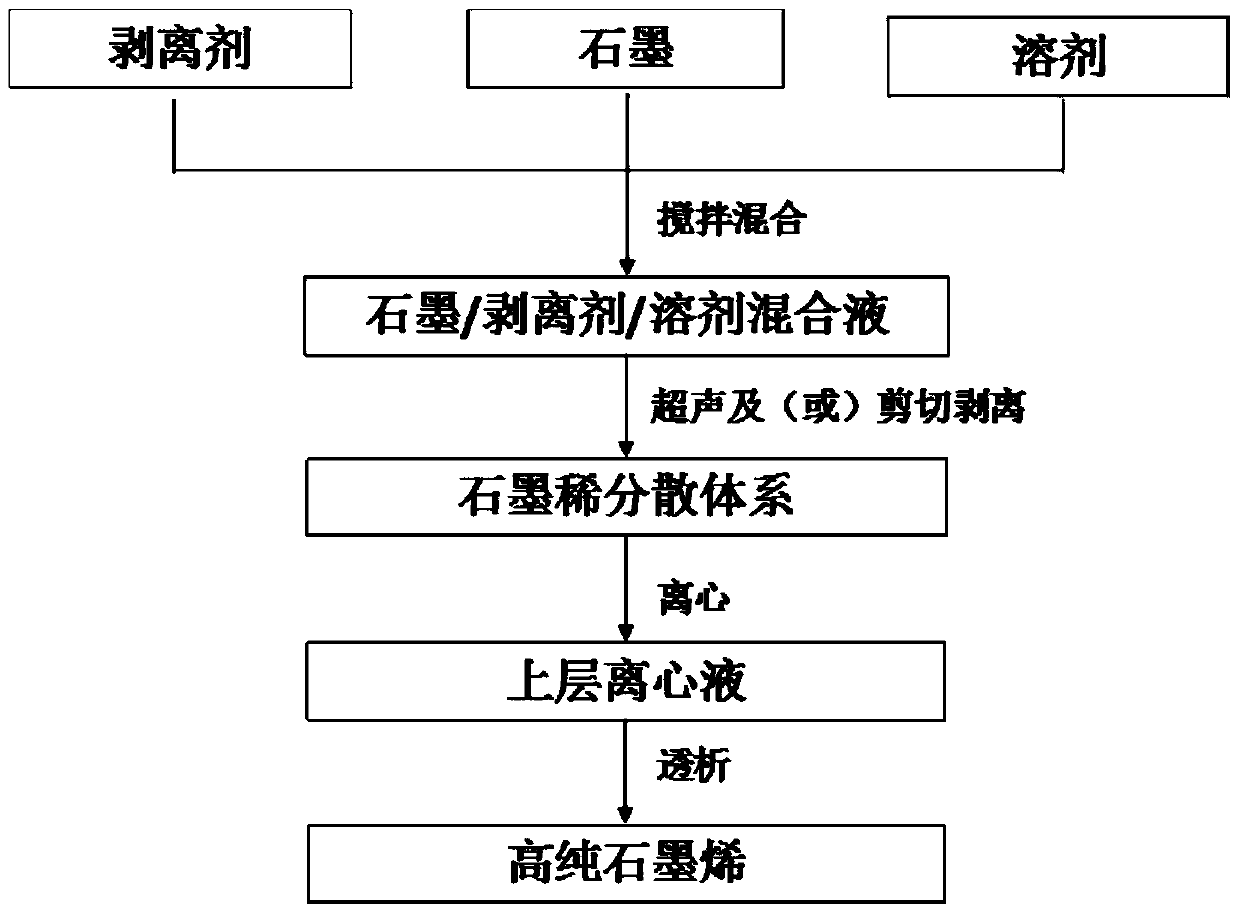

A kind of liquid phase exfoliation preparation method of graphene

A liquid-phase exfoliation and graphene technology, applied in the direction of graphene, single-layer graphene, nano-carbon, etc., can solve the problems of low production efficiency and poor product performance, and achieve low cost, high single-layer ratio and short preparation time short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The present embodiment provides a liquid phase exfoliation method to prepare graphene, and the basic operation steps are as follows:

[0033] In the first step, a hydroquinone aqueous solution with a concentration of 10 wt % was prepared, and 1 g of expanded graphite was dispersed in 999 g of the solution to obtain a mixed solution of 0.1 wt % graphite.

[0034] In the second step, the mixed liquid in the first step was processed by magnetic stirring for 5 hours to make it uniformly dispersed, and the stirring speed was 500 rpm to obtain the graphite pre-stripping dispersion.

[0035] In the third step, the graphite pre-exfoliation dispersion is subjected to ultrasonic exfoliation for 0.5 hours, and the selected ultrasonic frequency is 10KHz, and a graphene mixed dispersion system is preliminarily obtained.

[0036] The fourth step is to use a centrifuge to centrifuge the graphene mixed dispersion system. The selected centrifuge speed is 5000 rpm, the centrifugation tim...

Embodiment 2

[0040] The main difference from Example 1 is that in Example 2, the stripping agent was replaced, the concentration of graphite dispersion was increased, and the method of ball milling was used for mechanical stripping, and other relevant process parameters were changed at the same time.

[0041] The basic operation steps of graphene prepared by the present embodiment 2 liquid phase exfoliation method are as follows:

[0042] In the first step, a sodium phenoxide aqueous solution with a concentration of 0.5 wt% is prepared, and 1 g of oriented pyrolytic graphite is dispersed in 4 g of the solution to obtain a 20 wt % graphite solution.

[0043] In the second step, use magnetic stirring to process the mixed solution for 0.5 hour to make it uniformly dispersed, and the stirring speed is 2000rpm to obtain the graphite pre-stripping dispersion;

[0044]In the third step, the obtained graphite pre-exfoliation dispersion is poured into a ball mill tank, and zirconia is used as a bal...

Embodiment 3

[0049] The main difference from Example 1 is that in Example 3, the stripping agent solution was replaced, and the method of ultrasonic combined with shear emulsification was used for graphite stripping, and other relevant process parameters were changed at the same time.

[0050] Present embodiment 3 liquid phase exfoliation method prepares the basic operating steps of graphene as follows:

[0051] In the first step, a glycerol solution of catechol with a concentration of 1wt% is prepared, and 1g of graphite oxide powder is dispersed in 9g of the solution to obtain a mixed solution of 10wt% graphite.

[0052] In the second step, magnetic stirring was used to process the mixed liquid for 3 hours to make it uniformly dispersed at a stirring speed of 1000 rpm to obtain a graphite pre-stripping dispersion.

[0053] In the third step, the obtained graphite pre-exfoliation dispersion was subjected to ultrasonic exfoliation for 5 hours, and the selected ultrasonic frequency was 20 k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com