Hybrid power forklift transmission system

A transmission system and hybrid power technology, applied in the direction of lifting devices, etc., can solve the problems of high cost, complex structure, long charging time, etc., and achieve the effects of reducing energy conversion links, improving system efficiency, and facilitating assembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

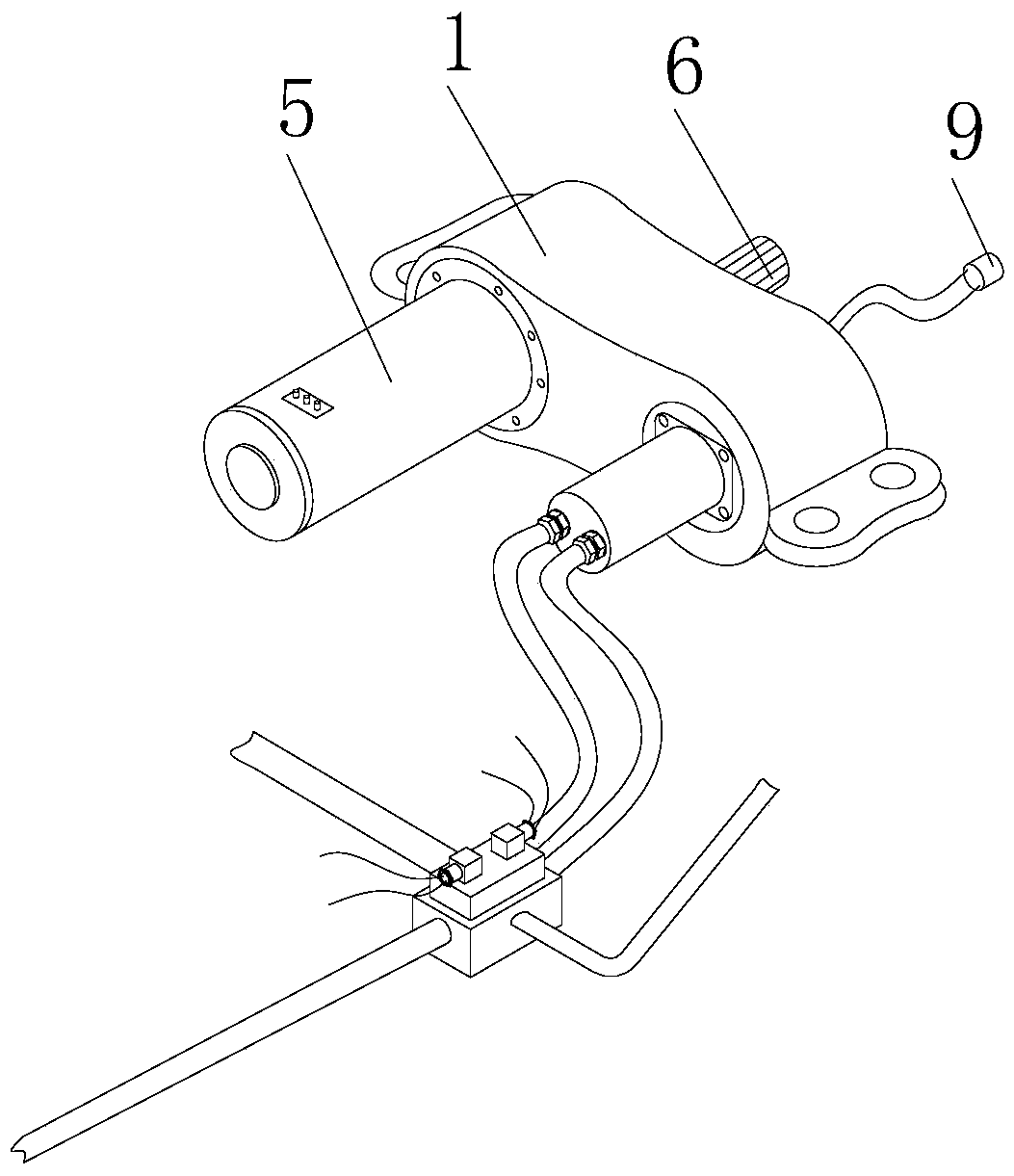

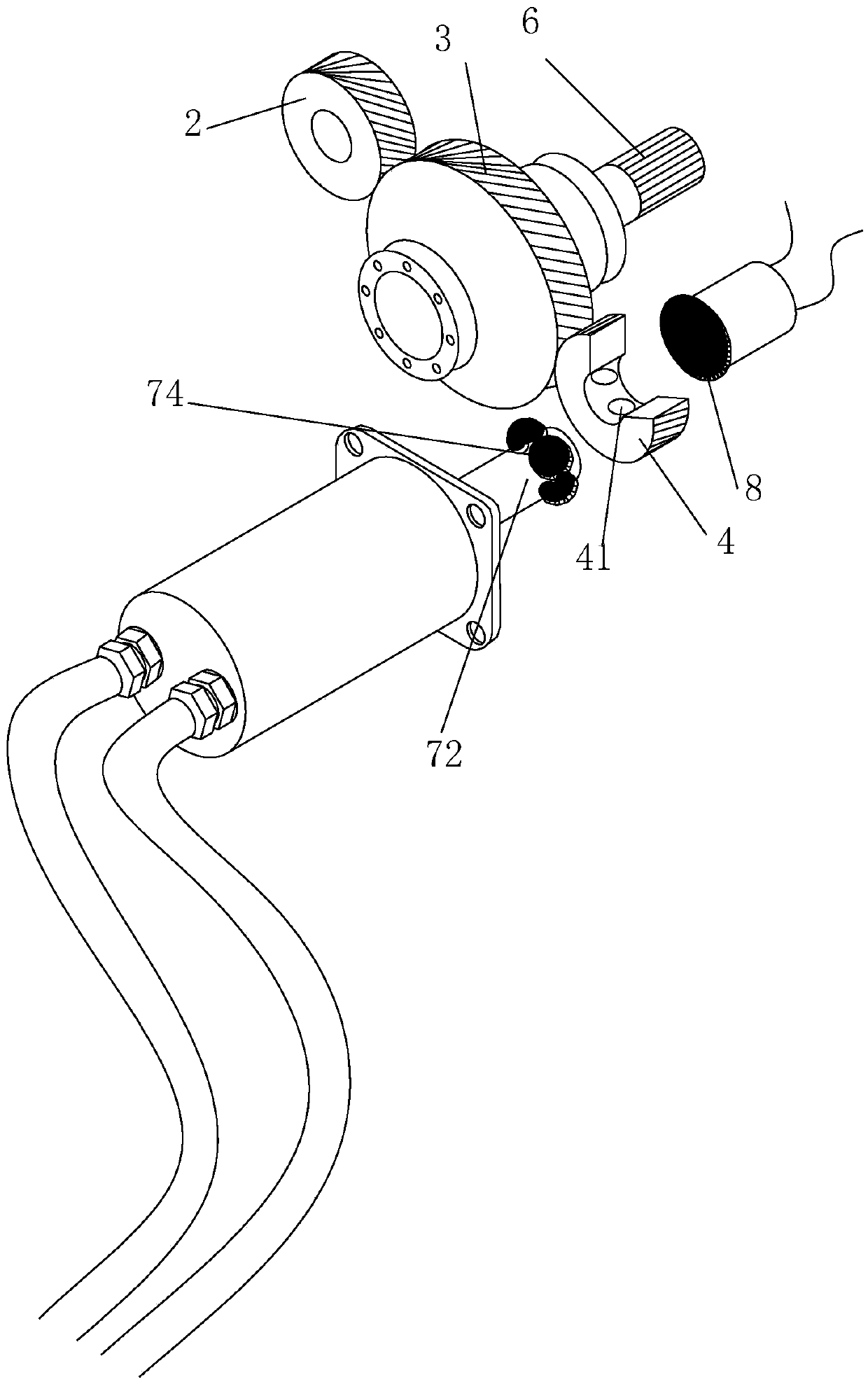

[0022] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a hybrid power forklift transmission system proposed by the present invention includes an adjustment box 1, a first gear 2, a second gear 3, a third gear 4, a drive motor 5, an output shaft 6, a hydraulic motor, an electromagnet 8, Control device, sensor 9 and solenoid valve;

[0023] The first gear 2, the second gear 3, and the third gear 4 can all be rotatably installed in the adjustment box 1, the first gear 2 and the third gear 4 are all meshed with the second gear 3, and the driving motor 5 is driven to connect the first gear 2 ; The output shaft 6 is installed on the second gear 3;

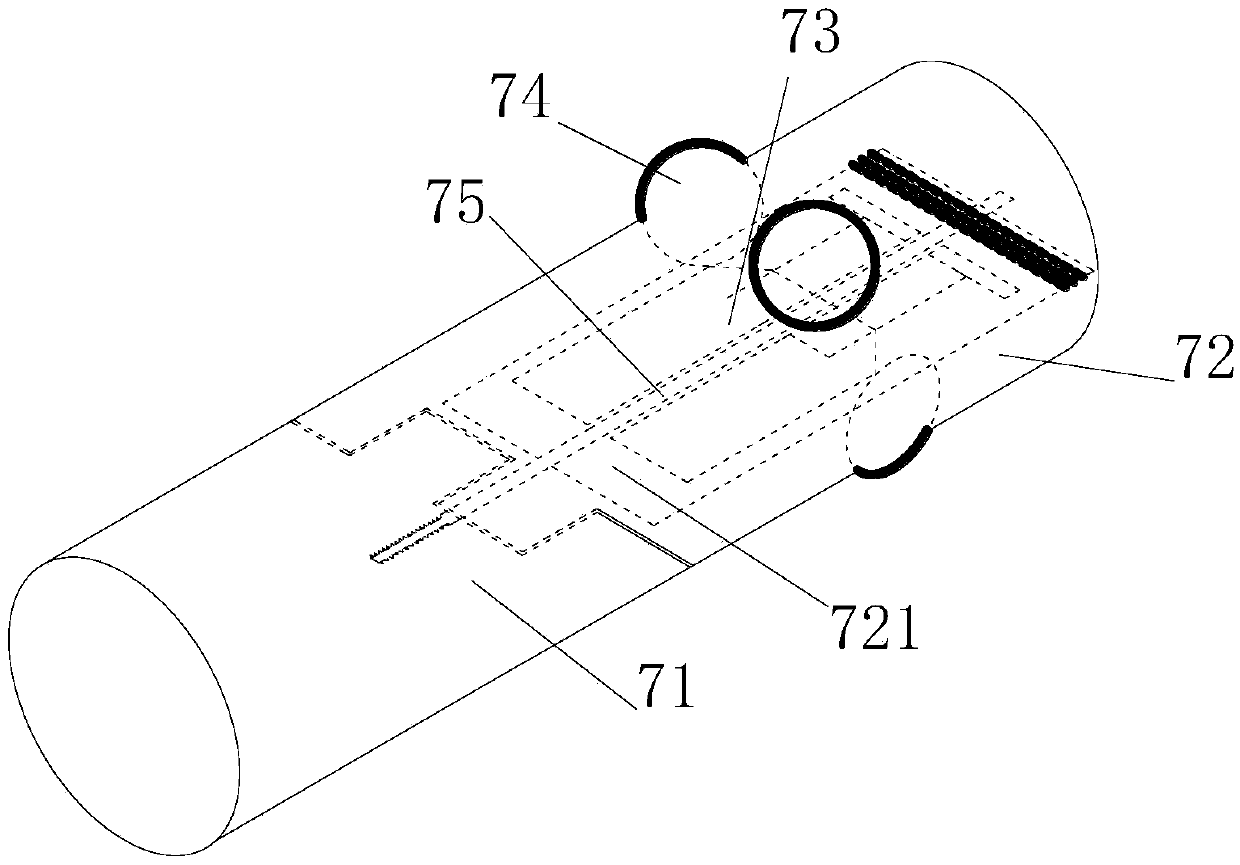

[0024] The hydraulic motor includes a motor shaft 71, a shaft head 72, a magnetic column 73, at least one steel ball 74 and a fixing bolt 75; the shaft head 72 is installed on the motor shaft 71, and a sliding groove 721 is provided in the shaft head 72; the magnetic column 73 is movable In the sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com