Disassembly-prevention recognition and remote stopping system for hydraulic grab and control method thereof

A hydraulic grab and anti-dismantlement technology, applied in the field of hydraulic grabs, can solve problems such as losses, legal disputes, accidents, etc., and achieve the effect of preventing accidental failures of grabs and preventing accidental failures of hydraulic grabs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

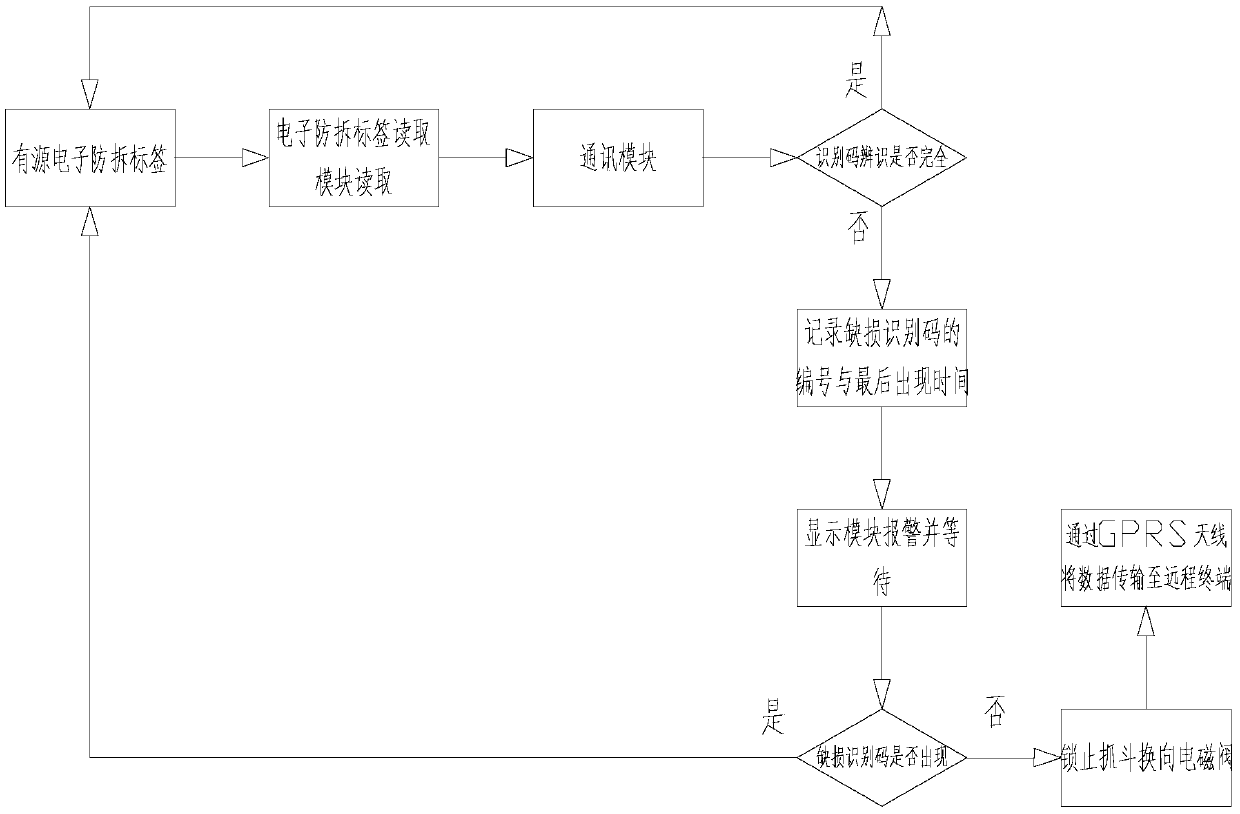

[0022] Hydraulic grab tamper recognition and remote stop system, including: active electronic tamper tag installed on the hydraulic grab, electronic tamper tag reading module for reading active electronic tamper tag information, and electronic tamper Remove the on-site display terminal unit connected to the tag reading module that can control the grab to stop.

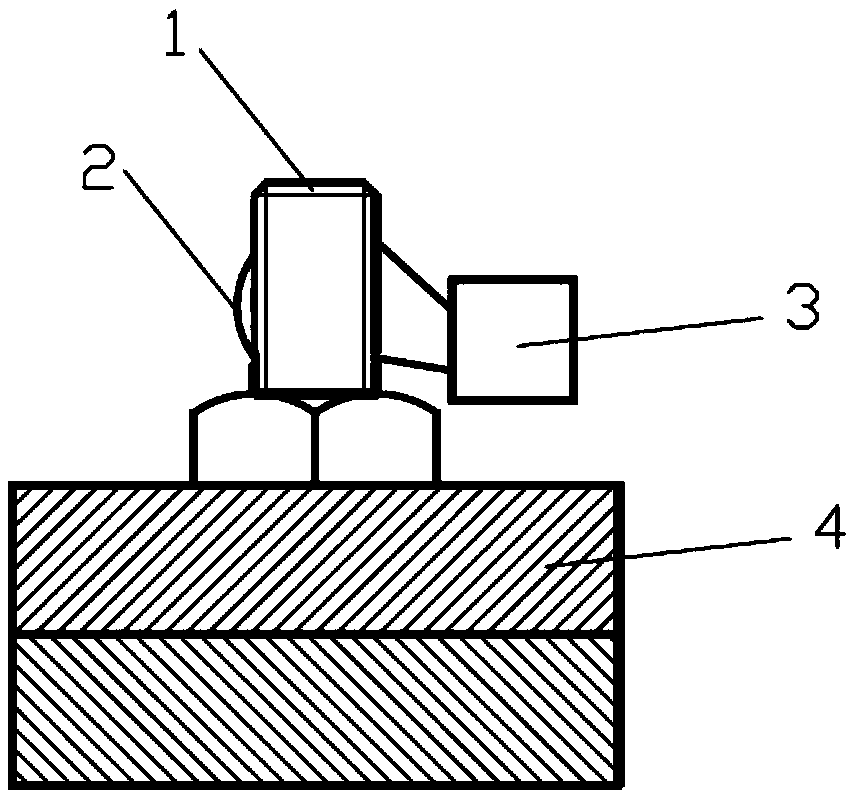

[0023] The active electronic tamper-resistant tag is a high frequency / very high frequency transmitter with a built-in power supply. During normal operation, the tag will transmit a pre-programmed identification code at a certain frequency. Change the fixed end of the label to an anti-demolition wire, which is suspended on the fixing bolts of key components (such as hydraulic pumps, moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com