Outer isolation integral double-component glue container

A two-component glue, one-piece technology, applied in the container field of mixing and applying glue, can solve the problems of affecting the performance of the glue, inconvenient use, difficult to uniform glue, etc., to achieve easy portability and use, simple structure, The effect of guaranteeing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Such as figure 1 As shown, first inject a certain amount of component B with a lower density into the bottom of the plastic tube bag with a rubber injection tube, then gather the bag neck 14a, fold the layers horizontally, and tie them tightly with a string 14c, at this time the lower container 16 is formed, After the upper container 10 is filled with component A in proportion, the bottle cap 18a containing the sealing member is screwed tightly, and finally the rubber extruder 8 with a one-way ratchet bar and a snapping orifice is arranged at the lower end. When in use, remove the bundled cord 14c first, let the denser component A flow into component B, mix the rubber materials by shaking, turning and kneading, and finally unscrew the bottle cap 18a, the rubber materials are squeezed Under the action of pressure, the static mixer 18 brought to the double tank through the inner wall is further mixed and then flows out from the bottle mouth.

Embodiment 2

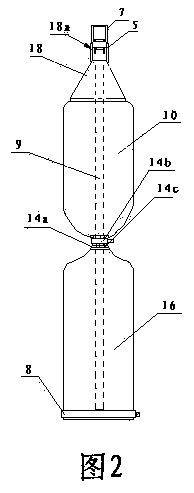

[0043] Such as figure 2As shown, a plastic stirring rod 9 can also be arranged along the longitudinal direction of the barrel bag, the stirring rod 9 runs through the upper container 10 and the lower container 16, and the upper end stretches out from the bottle mouth 18a and is fixed on a corresponding On the bottleneck 18a of structure, seal protective cover 7 is established between the upper end of stirring rod 9 and the bottleneck. When injecting glue and assembling, you can first inject component B with a lower density into the lower container 16 through a hose or a needle tube, install the seal and insert the stirring rod 9, and then attach the neck 14a of the lower container 16 to the stirring rod 9 Tighten it with a rope 14c, turn it up and down several times, and then use a cable tie or a clamp 14b to fully tighten the mouth of the barrel bag 14a, then inject the formed upper container 10 into component A with a higher density in proportion, and screw it Put on the s...

Embodiment 3

[0045] The isolation layer of the present invention can also take double or multiple protections such as twisting, folding, knotting, rope knotting, and ring-shaped holding clips at the same time, and the flexible area 14a between the upper container 10 and the lower container 16 is first tied up tightly with a rope 14c Solid, then clamp with ring-shaped clamp or hoop 14b. Glass, stainless steel, steel, ceramics, cement, and glass fiber reinforced plastics with a certain weight that do not react with both components can also be used, such as columnar glass with a diameter larger than the middle of the glue outlet. The short stick 9c is placed in the flexible area 14a between the two containers, and the rope 14c is used to tie the looped groove around the outer wall of the flexible area 14a with a slipknot. In the hoop 14b of the shape ditch, the short glass rod 9c acts as an oscillating stone. In order to enhance the mixing effect of two-component glue, if necessary, one to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com