Pretreatment device allowing air to be automatically discharged from IC card in thermolaminating process

A pretreatment device and automatic exhaust technology, which is applied in the lamination device, lamination, layered products, etc., can solve the problems of non-uniform position, manual piercing, time-consuming and labor-intensive, etc., and achieve the uniform position of the vent hole , Ensure exhaust quality, accurate and efficient effect of punching holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

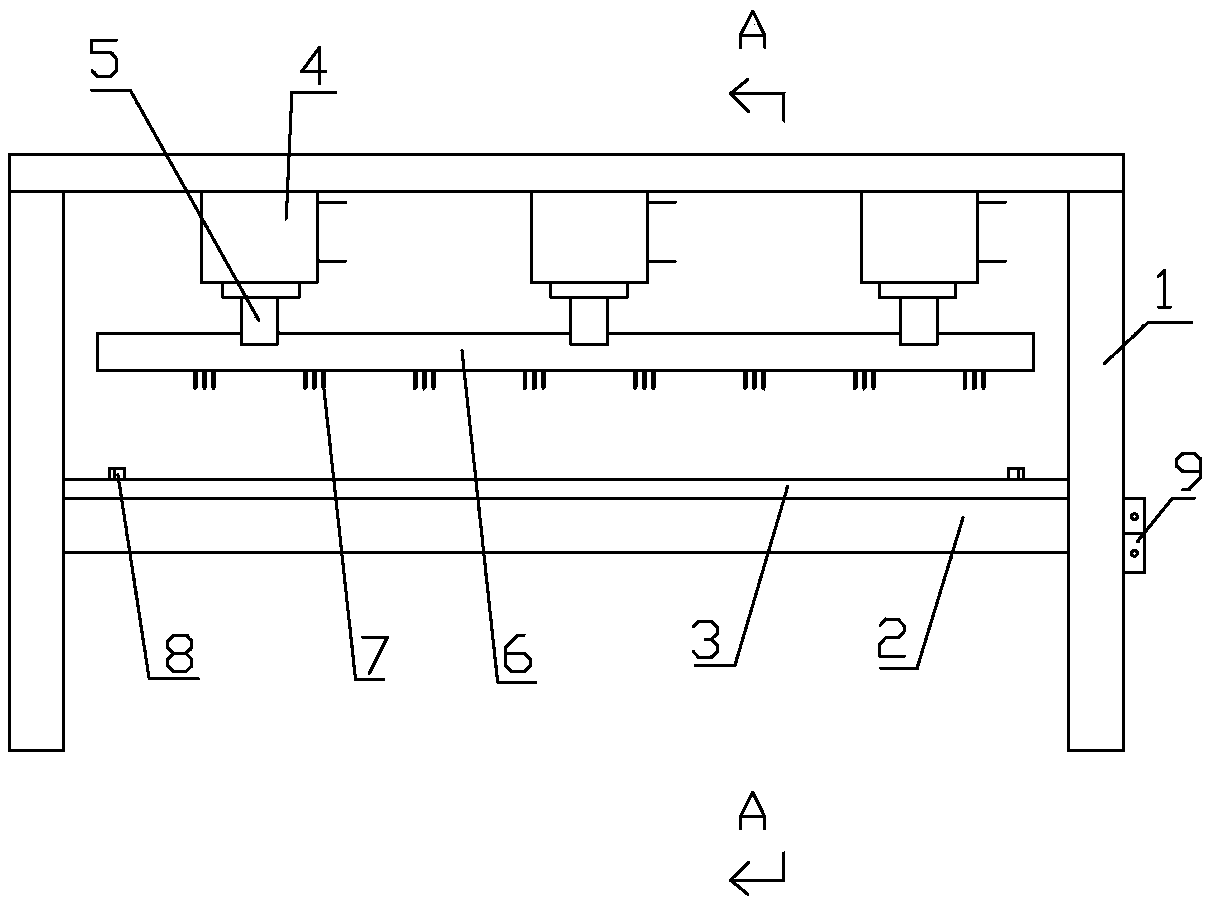

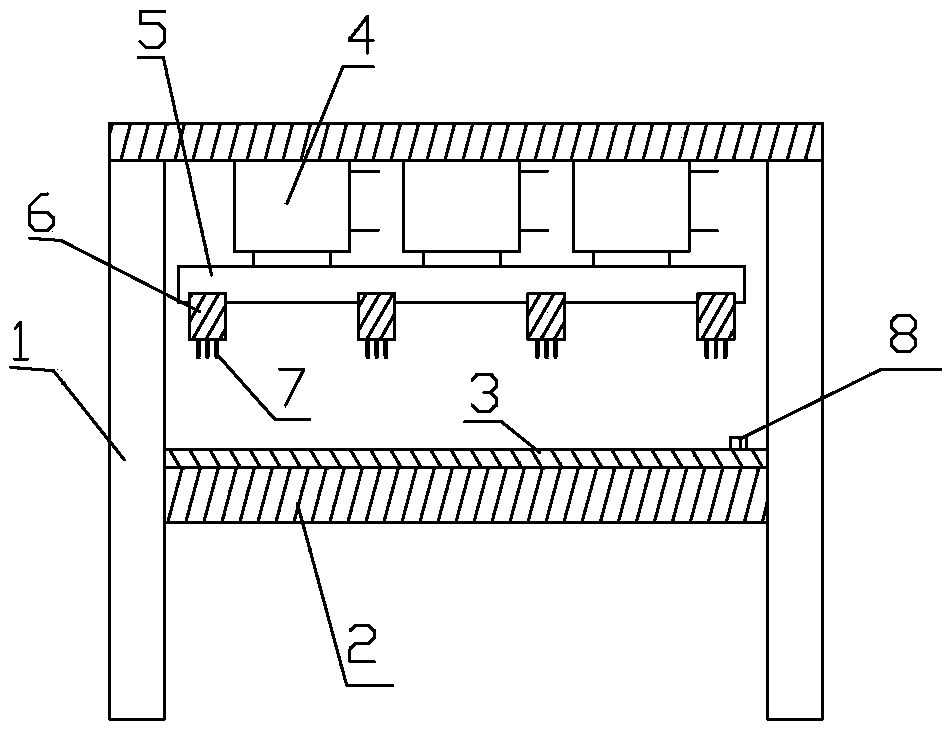

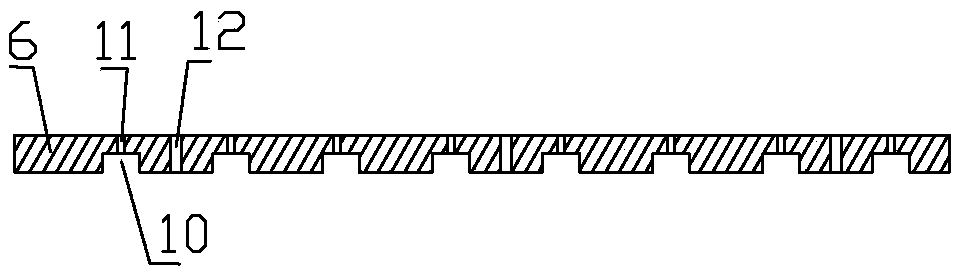

[0018] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 Make the invention. The pretreatment device for automatically exhausting the IC card during the thermal lamination process includes a frame 1 and a material pallet 3, the middle part of the frame 1 is fixed with a transverse partition 2, and the material pallet 3 is arranged on the transverse partition 2, the material pallet 3 is compatible with the PETG leveling layer of the IC card, so that the PETG leveling layer can be stored on the material pallet 3 for punching operations. There are 32 modules on a PETG leveling layer. It is in four rows and eight columns, and is characterized in that: a mobile positioning device is provided above the material pallet 3, the upper part of the mobile positioning device is fixedly arranged on the lower part of the top plate of the frame 1 through a double-acting cylinder 4, and the bottom panel of the mobile positioning device There are pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com