Exhaust device, assembling method thereof and tire mold with exhaust device

A technology for exhaust devices and vent holes, which can be applied to other household appliances, tires, household appliances, etc., and can solve the problems of enlarged air hole diameter of tire molds, high maintenance costs of tire molds, complicated disassembly and replacement of exhaust devices, etc. , to achieve the effect of increasing life, reducing maintenance costs and facilitating cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

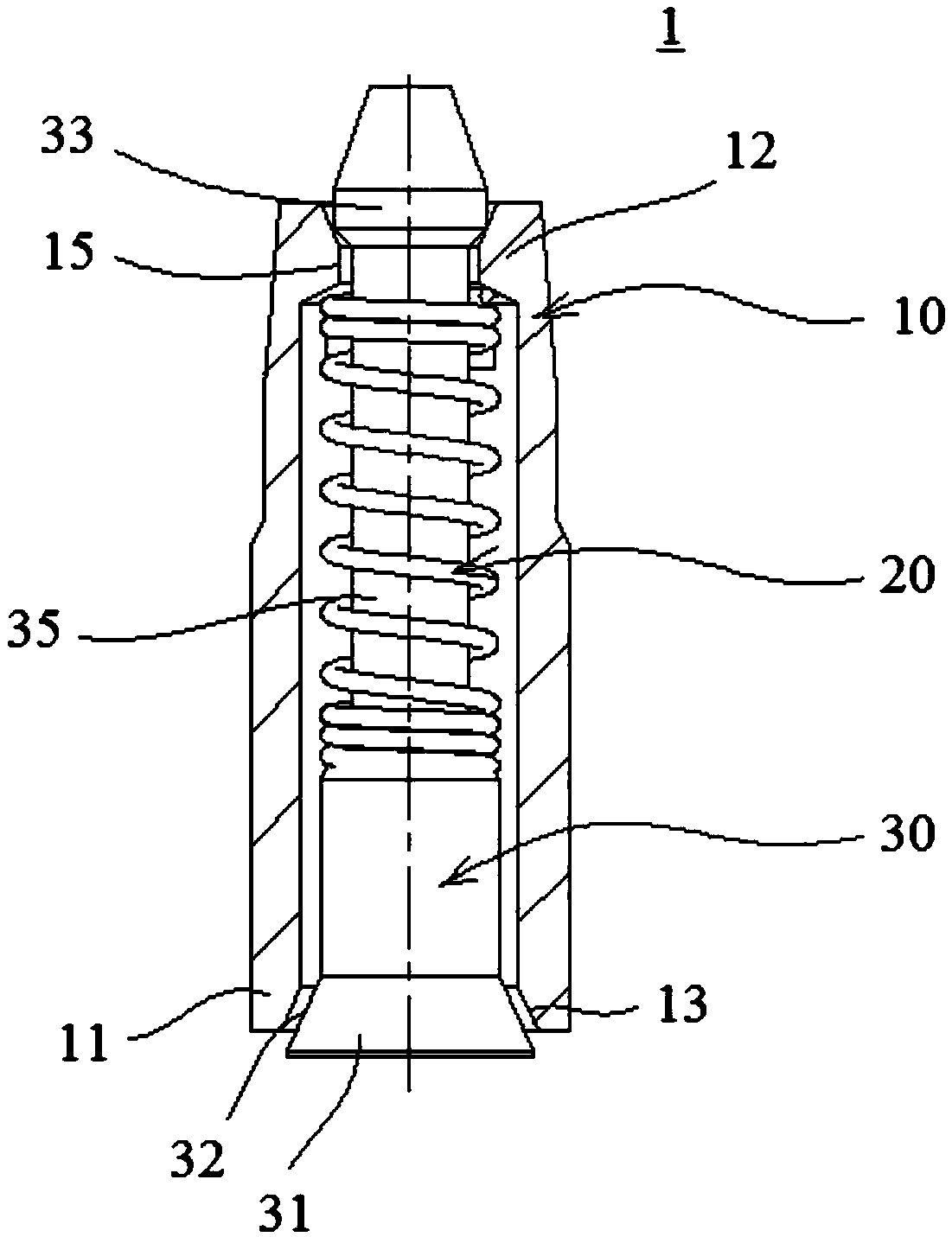

[0042] figure 1 A cross-sectional view of the exhaust device 1 of the present invention is shown. Such as figure 1As shown, to include a casing 10 , a spring 20 and a mandrel 30 , the spring 20 is sleeved on the outer surface of the mandrel 30 and inserted into the casing 10 together with the mandrel 30 .

[0043] The inner peripheral surface of the first end 11 of the outer casing 10 (the end facing the inside of the tire mold in the assembled state) is formed with an outer casing tapered surface 13, and is formed at the second end 12 of the outer casing 10 opposite to the first end 11. There are small hole parts 15 in the jacket.

[0044] A shaft head 31 is formed on an end of the mandrel 30 corresponding to the first end 11 of the casing 10 , and a shaft head cone 32 is formed on an outer peripheral surface of the shaft head 31 . In the assembled state, the mandrel 30 is movable in the outer casing 10 between a first position and a second position, wherein in the first...

no. 2 example

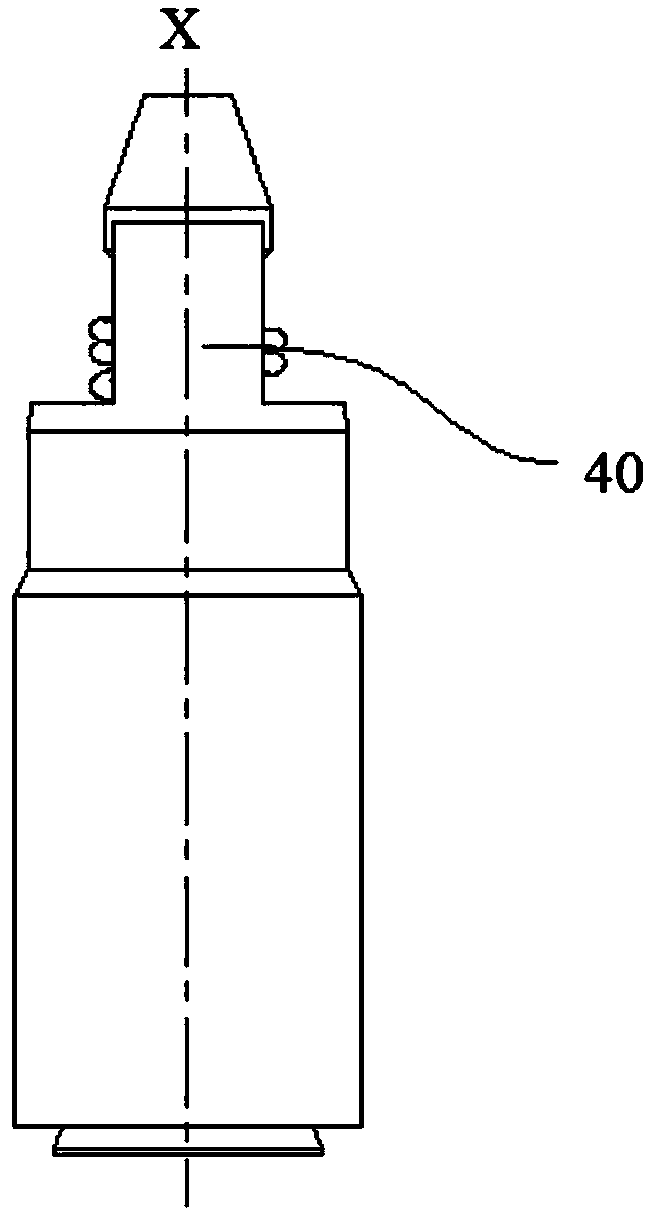

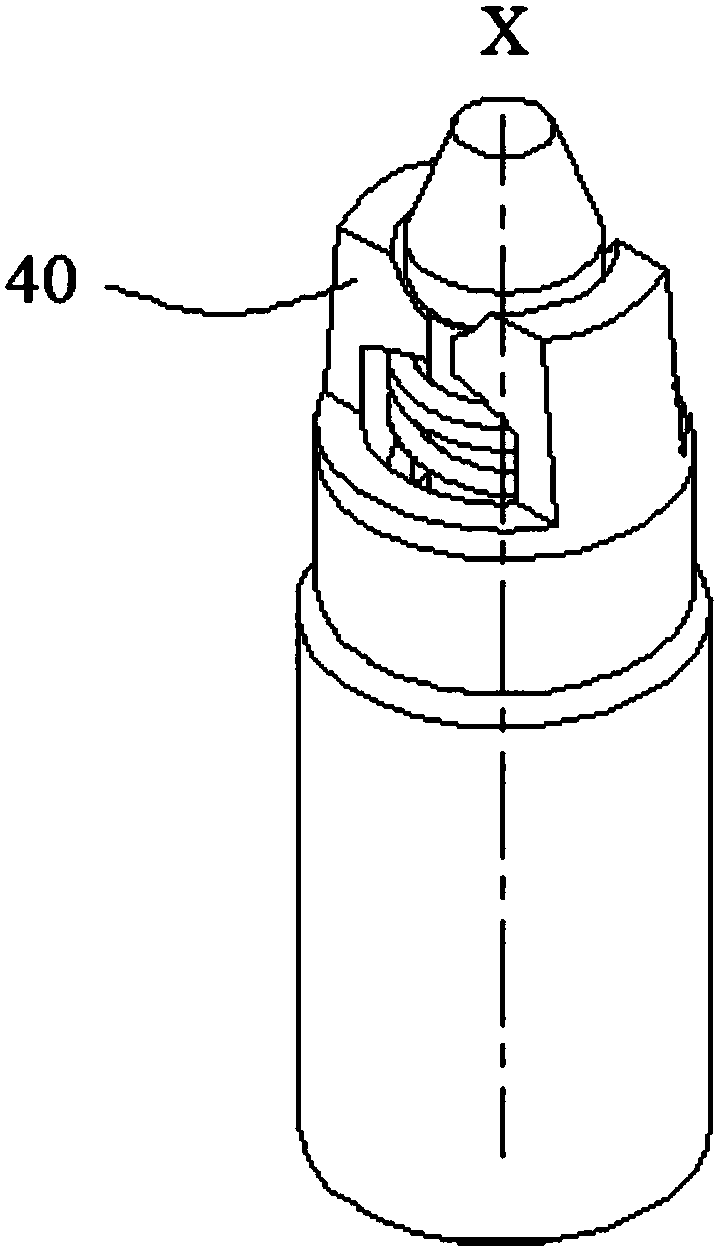

[0067] Figure 6-8 A second embodiment of the invention is shown. Different features between the second embodiment and the first embodiment will be mainly described below. In addition, unless stated to the contrary, the content described in the first embodiment is also applicable to the second embodiment, and will not be described in detail here. Furthermore, in the description of the second embodiment, the same features are given the same reference numerals as those of the first embodiment.

[0068] In the second embodiment, before assembly, the inner diameter of the outer casing small hole portion 15 of the outer casing 10 is set to be slightly larger than the maximum diameter of the small diameter end 33 of the mandrel 30, so that the outer casing small hole portion 15 and the small diameter end 33 can form a clearance fit. Such as Image 6 As shown, there may be a gap σ between the small hole portion 15 of the jacket and the small diameter end 33 , and the size of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com