Double coloured plastic injection machine

A technology of two-color injection molding machine and ejector mechanism, applied in the field of two-color injection molding machine, can solve the problems of increasing idle running time, reducing production efficiency, and lengthening the ejection stroke of ejector rod.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

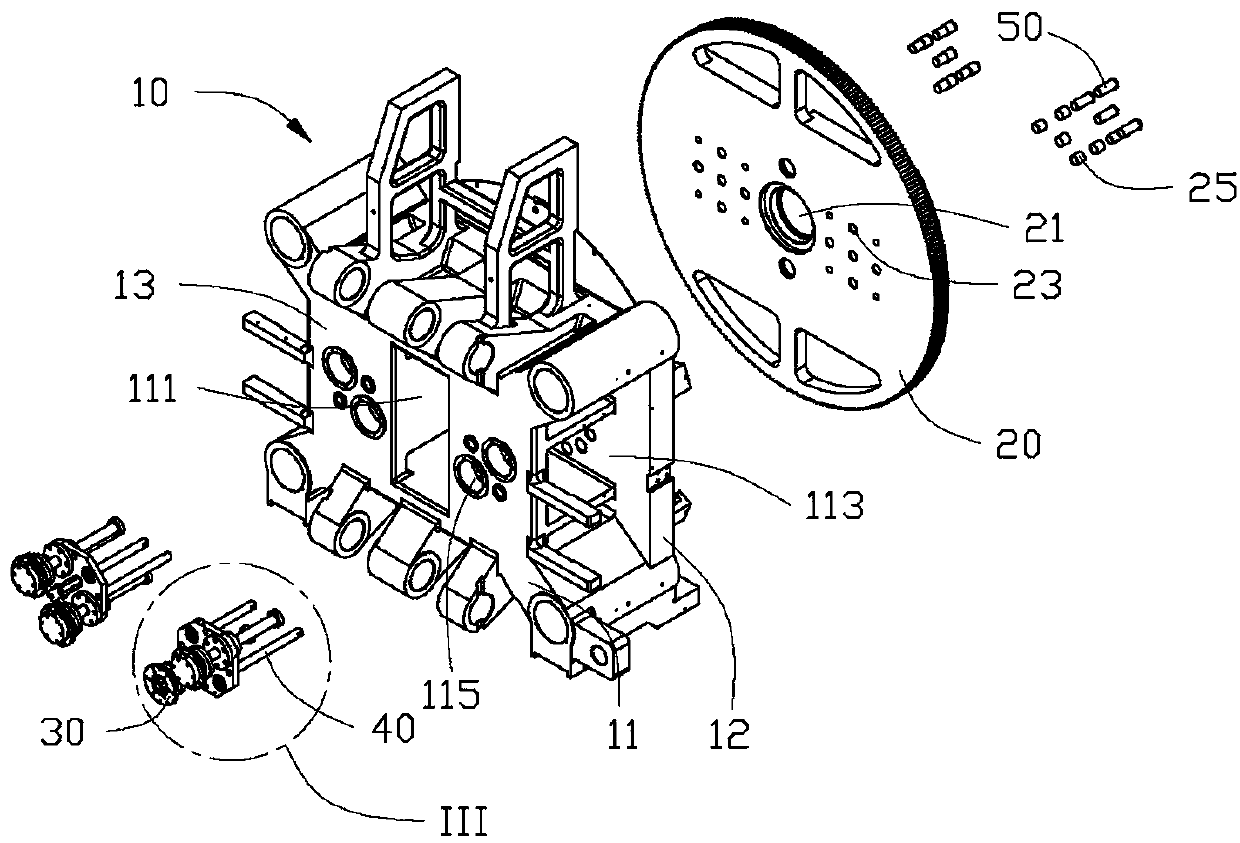

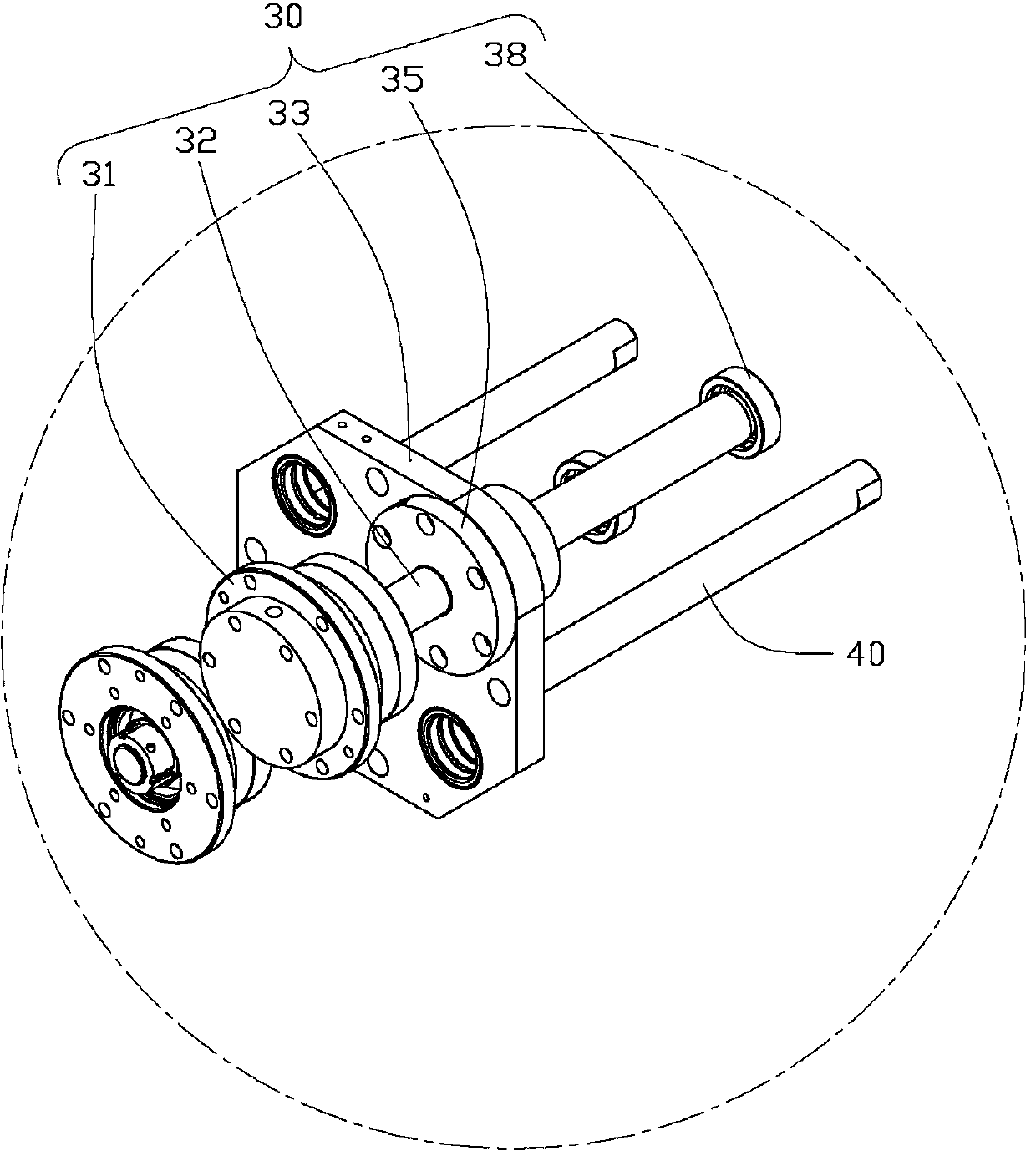

[0017] see figure 1 , The preferred embodiment of the two-color injection molding machine of the present invention includes a movable platen 10 , a turntable 20 , two ejection mechanisms 30 , several ejector rods 40 and several extension rods 50 .

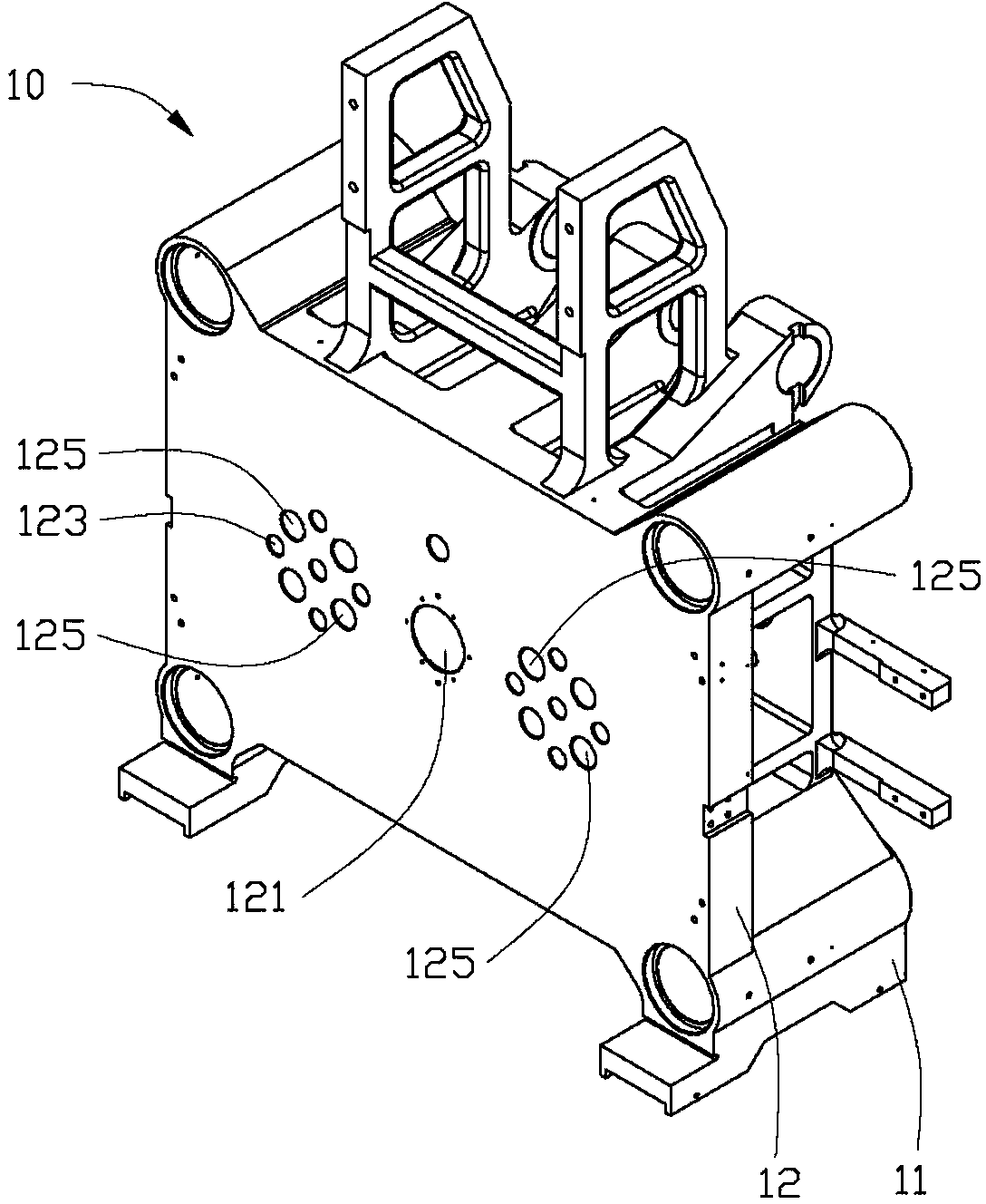

[0018] Please also refer to figure 2 , the movable template 10 includes a main body 11 . The main body 11 includes a first side panel 12 and a second side panel 13 opposite to each other. The main body 11 defines a cavity 111 located in the middle and passing through the second side panel 13 . The main body 11 is respectively provided with a slot 113 at two ends. The second side plate 13 defines two openings 115 respectively communicating with the two slots 113 on two sides of the cavity 111 . A central portion of the first side plate 12 defines a shaft hole 121 . The first side plate 12 defines a plurality of through holes 123 on both sides of the shaft hole 121 . The first side plate 12 defines two installation holes 125 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com