A kind of shear punching equipment and its processing technology for door panel

A door panel and equipment technology, which is applied in the field of door panel shearing and punching equipment and its processing technology, can solve the problems of door panel bending, heavy workload, damage, etc., and achieve the effect of convenient and quick door panel replacement and convenient punching and shearing operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

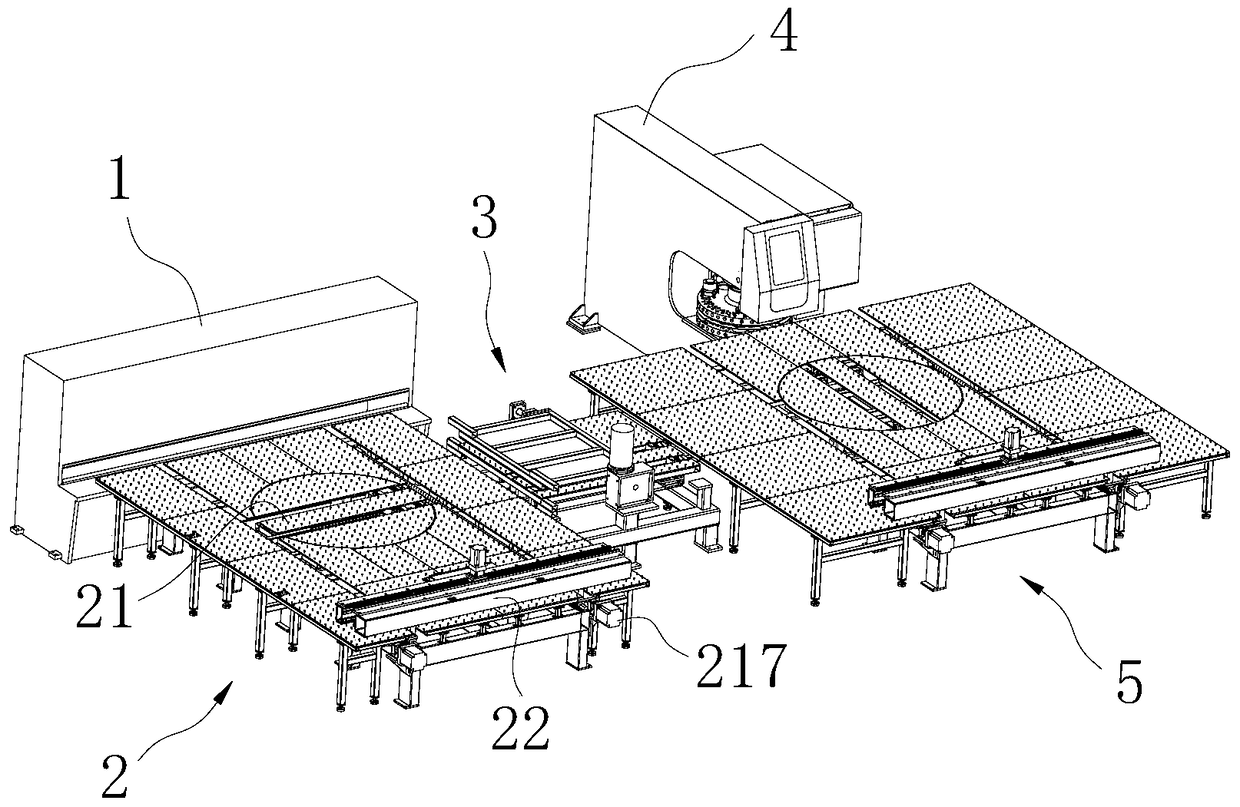

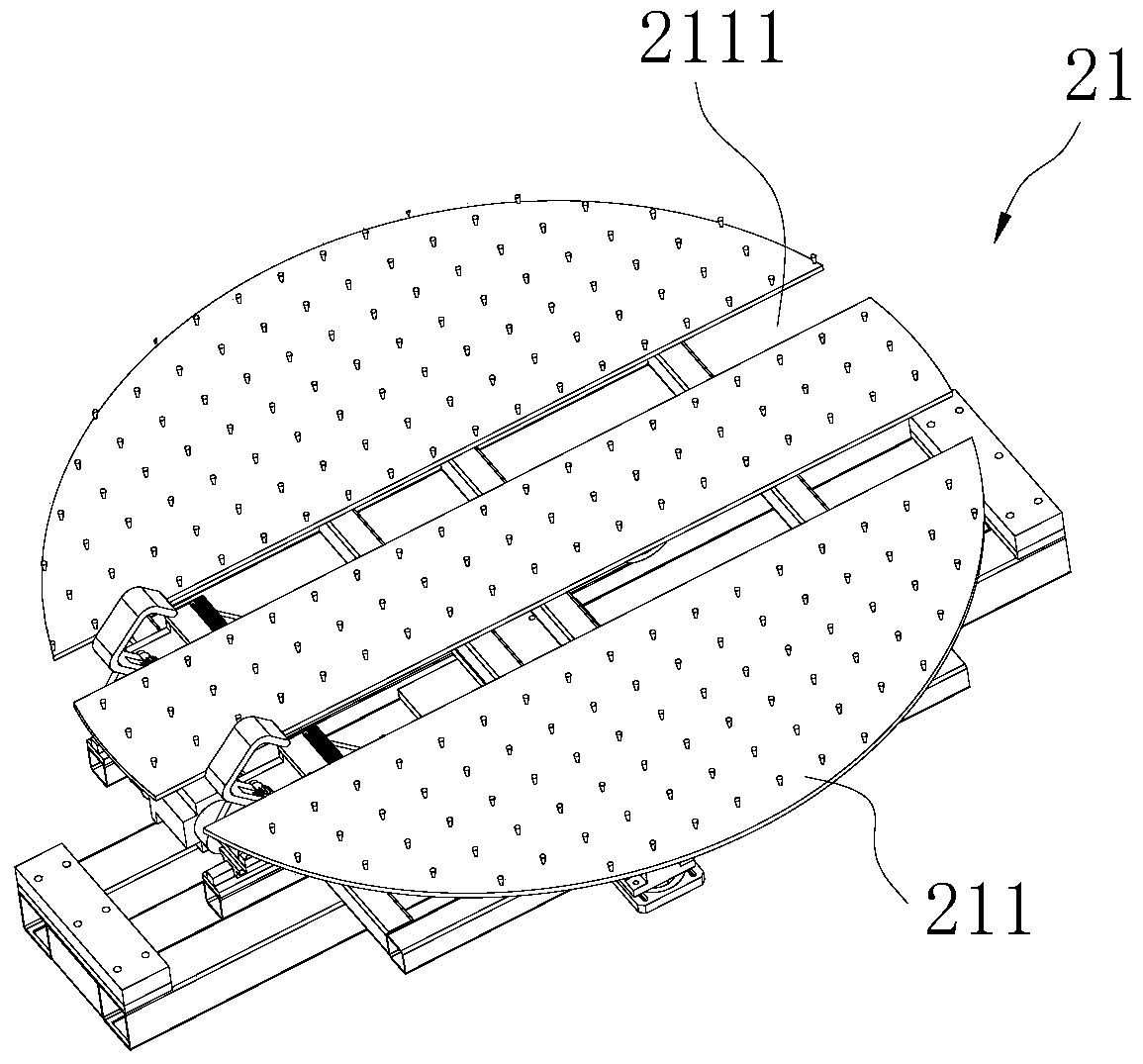

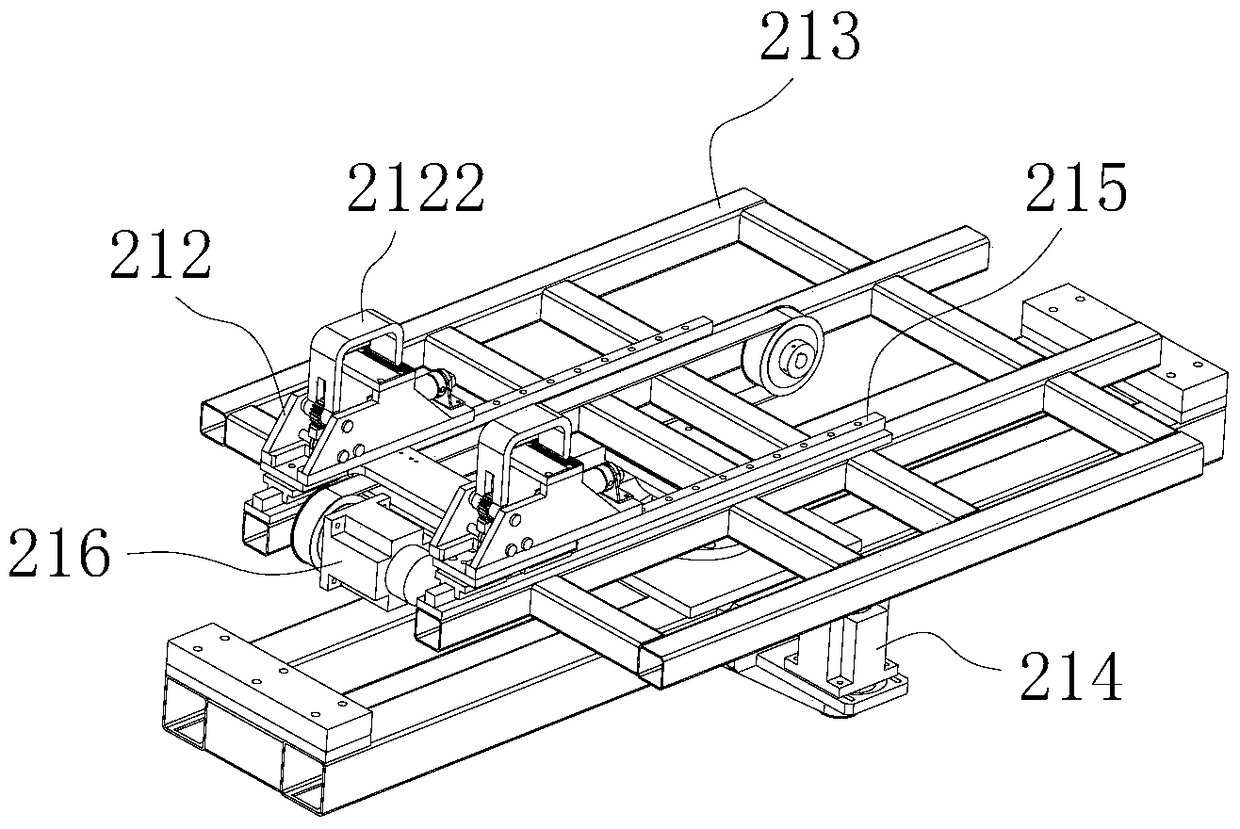

[0027] Such as figure 1 As shown, the shearing and punching equipment includes a shearing machine 1 and a punching machine 4, and also includes a first rotary table 2 connected horizontally with the inlet of the shearing machine 1, and a second rotary table 5 connected with the inlet of the punching machine 4, And the overturning device 3 that is arranged between the first rotary table 2 and the second rotary table 5 for door panel face-changing processing, the first rotary table 2 and the second rotary table 5 are all provided with a The rotary side changing mechanism 21, and the beam clamping mechanism 22 for the longitudinal feeding and lateral movement of the door panel. Preferably, the first rotary table 2 has the same structure as the second rotary table 5, and in order to allow the door pane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com