Building curtain wall

A curtain wall and building technology, applied in the direction of building, building components, building structure, etc., can solve the problems of poor aesthetics, dull building shape, dull color and matching, etc., to achieve rapid replacement, improve thermal insulation capacity, and facilitate replacement face effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

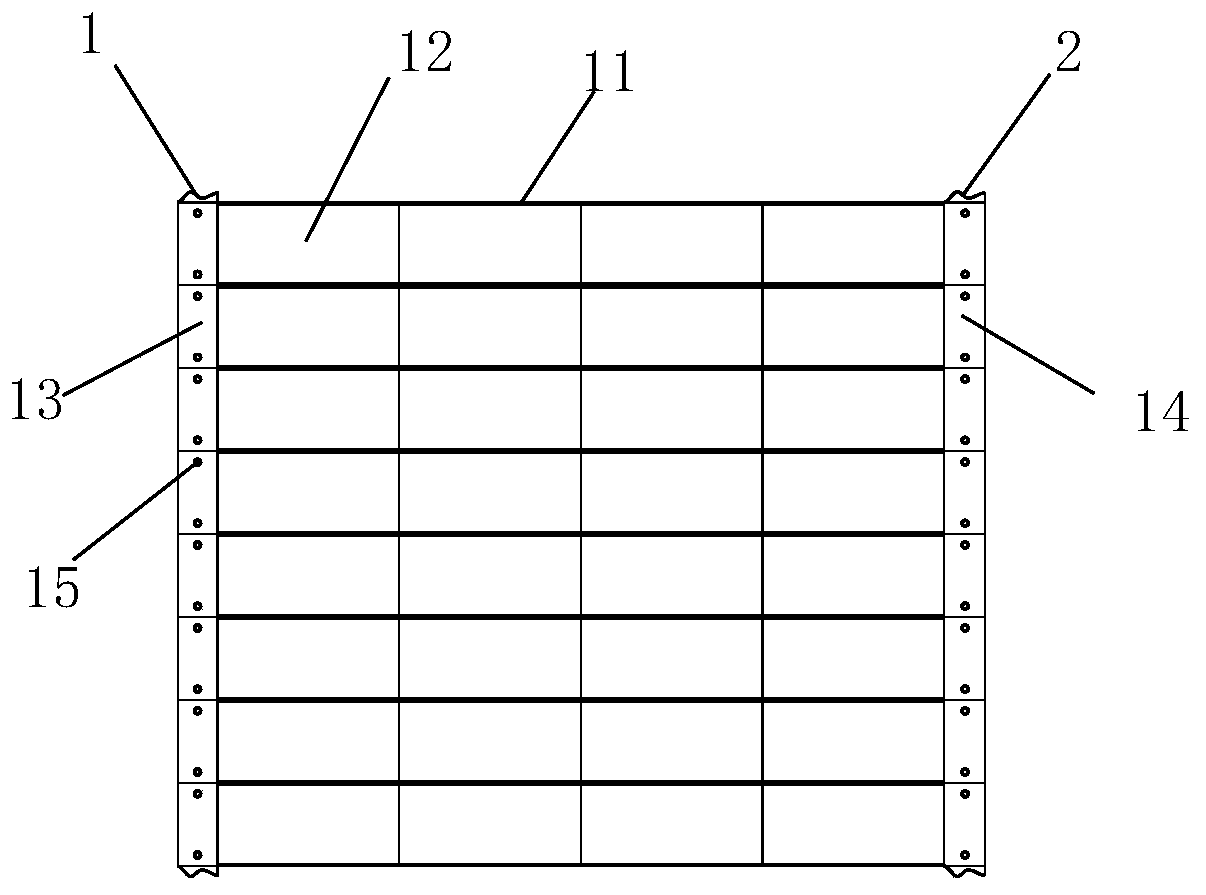

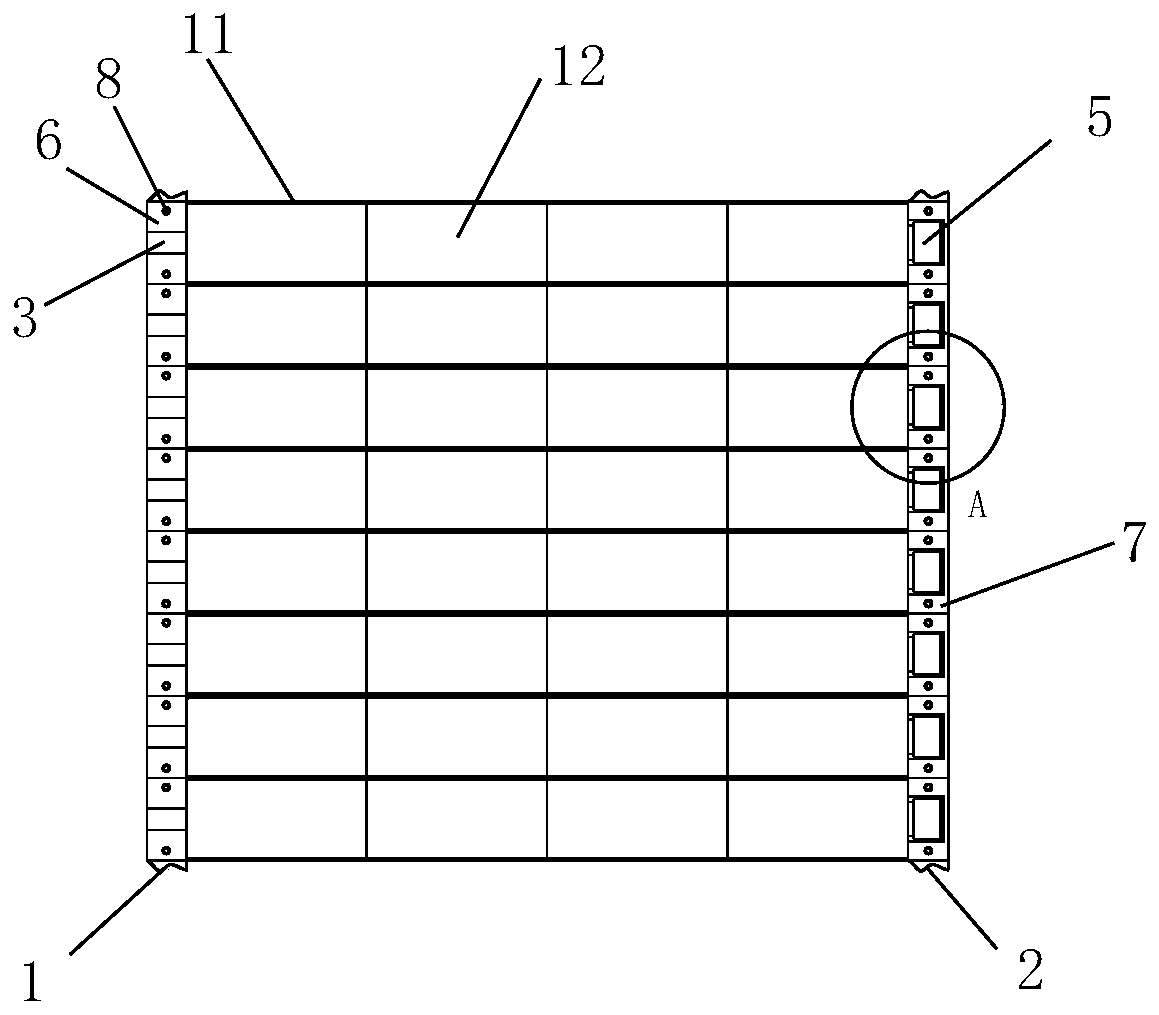

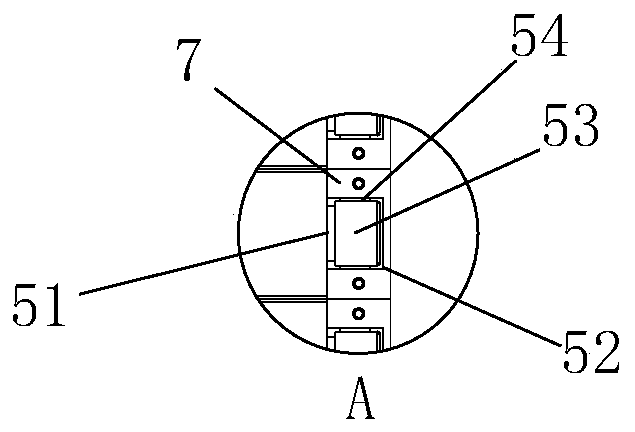

[0016] like figure 2 and Figure 4 As shown, the curtain wall of this building includes a first fixed rod 1 installed on the outer wall of the building and a second fixed rod 2 parallel to the first fixed rod 1, and a first fixed rod 1 and the second fixed rod 2 form a In the curtain wall installation cavity, the front end surface of the first fixing rod 1 is provided with more than one first assembly groove 6 from top to bottom, and the bottom surface of the first assembly groove 6 is provided with a first buckle groove (not shown), and a second The front end surface of the fixing rod 2 is provided with more than one second assembly groove 7 from top to bottom, the bottom surface of the second assembly groove 7 is provided with a second buckle groove 52, and the two sides of the second buckle groove 52 are respectively provided with a shaft hole. (not shown), a group of curtain wall groups are installed between the adjacent first and second assembly grooves, each group of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com