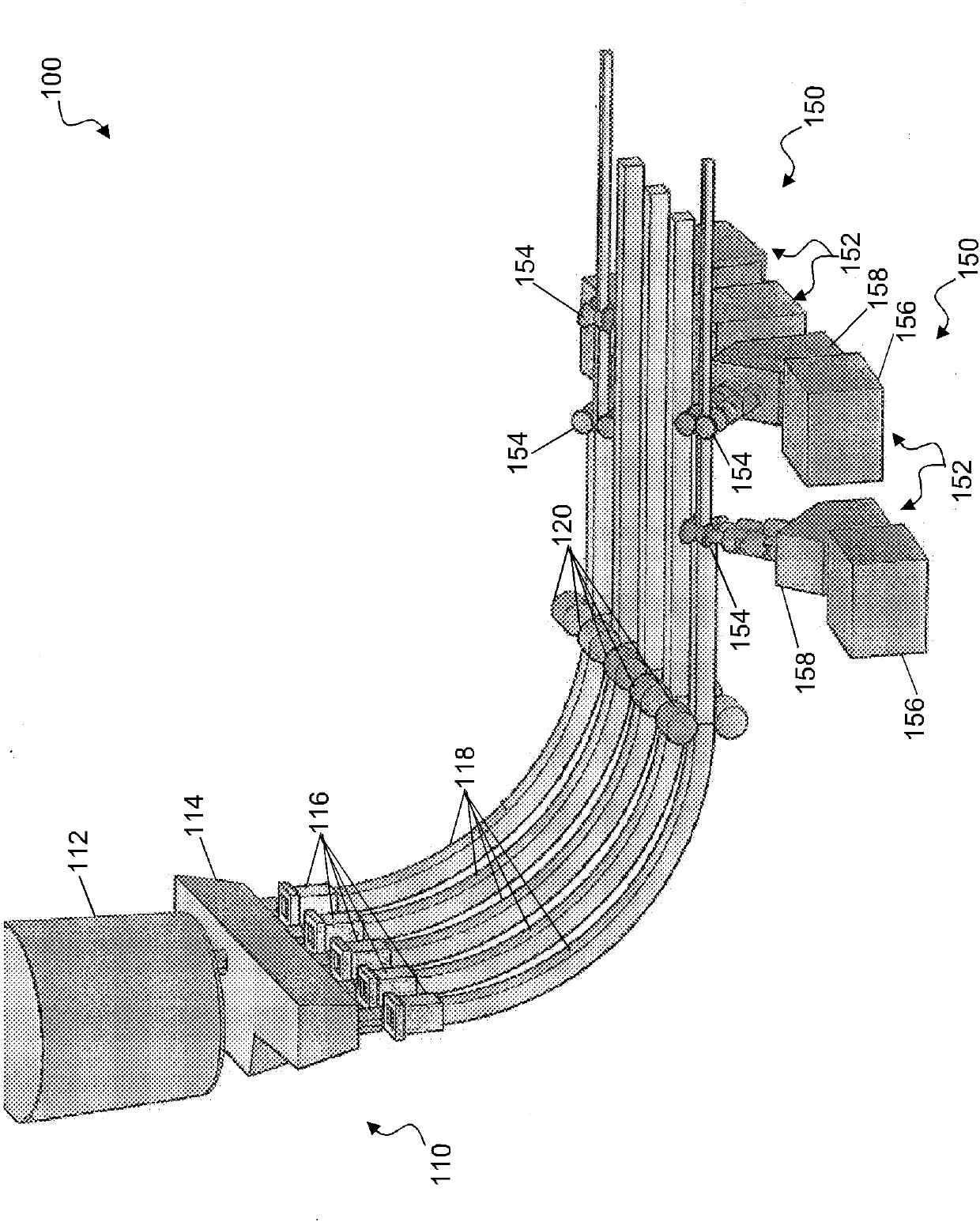

Method and apparatus for producing steel intermediate products

A technology for semi-finished products and equipment, which is applied in the field of on-line rolling of steel billets from continuous casting blooms, and can solve the problems of not particularly efficient or efficient, high boundary loss rolling costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The detailed description set forth below in conjunction with the accompanying drawings is intended as an illustration of the presently preferred embodiments of the invention and is not intended to represent the only way in which the invention may be practiced. It is to be understood that the same or equivalent functions can be achieved by different embodiments, which are intended to be encompassed within the spirit and scope of the invention. Furthermore, the terms "comprising", "comprising" and any other variation thereof are intended to cover a non-exclusive inclusion, such that means and method steps comprising a series of elements or steps do not include only those elements but may include elements not expressly listed. Other elements or steps that are out or inherent in themselves. An element or step proceeded by "comprising" does not, without more constraints, exclude the presence of additional identical elements or steps comprising that element or step.

[0028]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com