Pipeline outer wall automatic rust removal device and method

An automatic technology for the outer wall of the pipeline, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve problems such as rust stains and pipeline leakage, and achieve the effects of convenient use, avoiding foreign body damage, and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

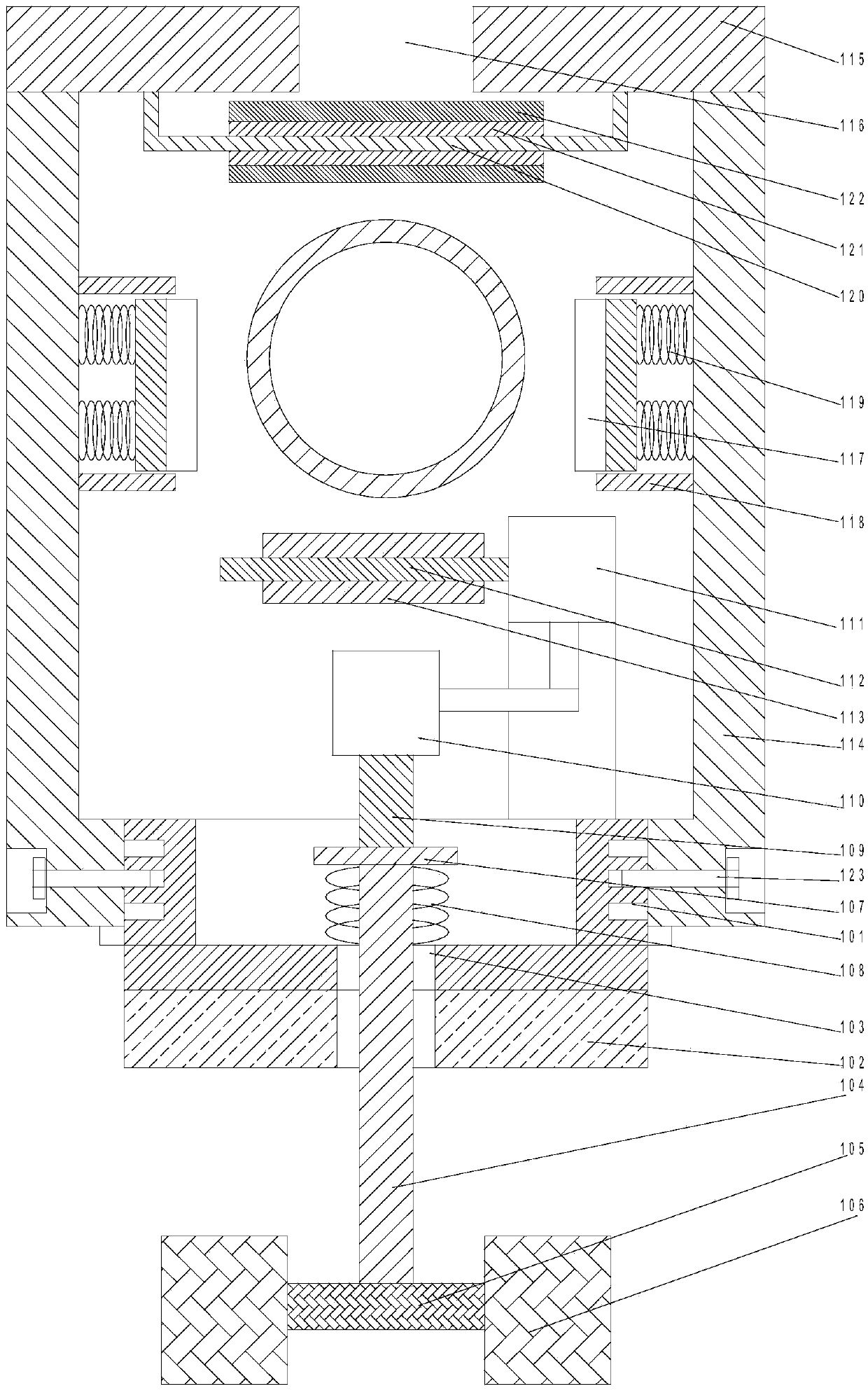

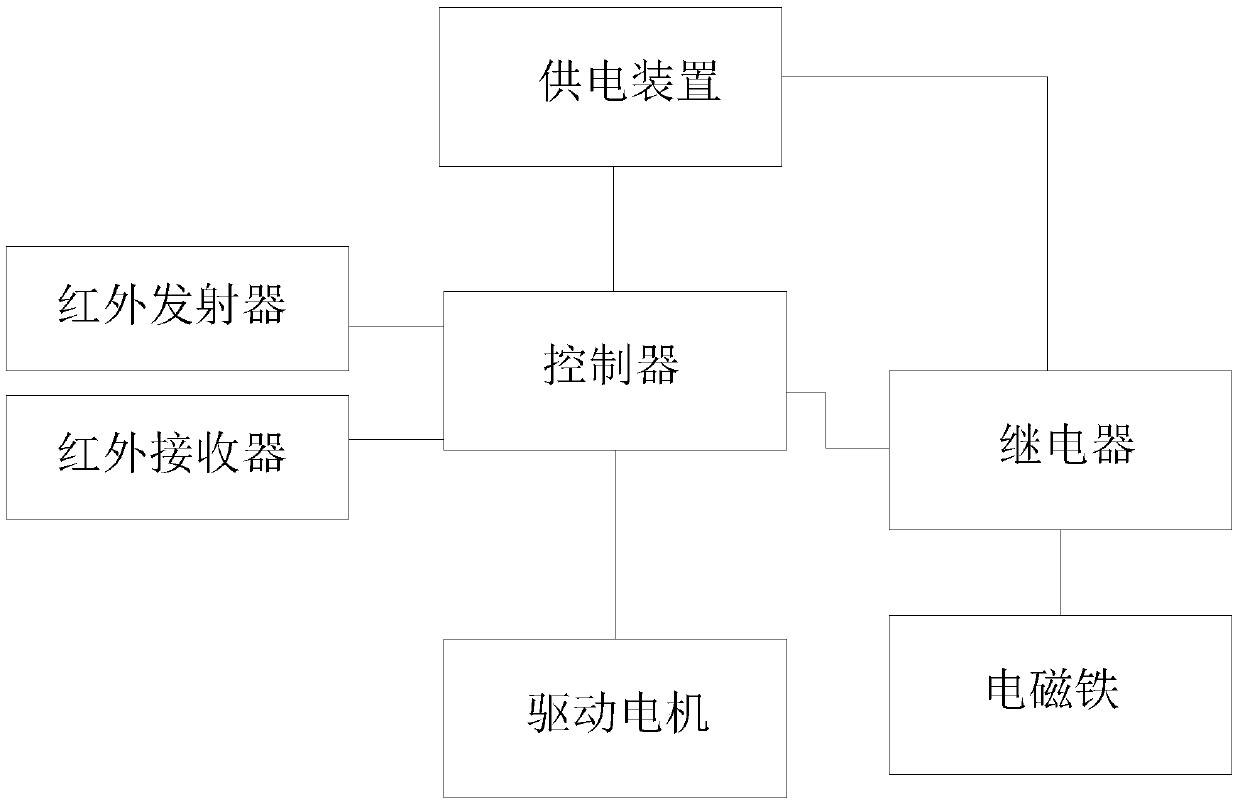

[0022] Such as figure 1 , 2 As shown, an automatic derusting device for the outer wall of a pipeline includes a bracket 101 and an electromagnet 102 arranged below the bracket 101. Threaded holes arranged at equal intervals are arranged in the height direction of the side walls on both sides of the bracket 101. Both sides of the bracket 101 are respectively provided with fixing frames 114, and through holes are respectively arranged on the two fixing frames 114, and fastening bolts 123 are arranged in the through holes, and the fastening bolts 123 Through the through hole and screwed into the threaded hole on the side wall of the bracket 101, a positioning plate 115 is respectively arranged on the upper ends of the two fixed brackets 114, and the two positioning plates 115 are arranged opposite to each other. A cavity 116 is provided between the facing end faces of the two positioning plates 115, the width of the cavity 116 is smaller than the diameter of the pipe, and on the...

Embodiment 2

[0028] In this embodiment, on the basis of Embodiment 1, the present invention also discloses a method for automatically removing rust from the outer wall of a pipeline, comprising the following steps:

[0029] S1: Fix the two positioning plates 115 above the pipe, fix the fixing frame 114 under the positioning plate 115, make the driving gear 113 under the pipe, and move the fixing frame 114 longitudinally, so that the fixing frame 114 is connected by fastening bolts 123 bolts On the side wall of the bracket 101, and adjust the height of the fixed frame 114 by adjusting the position of the threaded hole connected by the fastening bolt 123;

[0030] S2: The controller sends a driving signal to the relay, so that the electromagnet 102 is energized to attract the armature 106, the armature 106 drives the cross bar 105 to move upward, and drives the limit plate 107 to move upward, and the limit plate 107 pushes the support rod 109 to move upward, so that the drive gear 113 is fit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com