Cleaning disk brush

A technology for cleaning cloth and discs, which is applied to cleaning flexible objects, cleaning methods and utensils, cleaning methods using tools, etc., and can solve the problems of low efficiency of batch tablets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

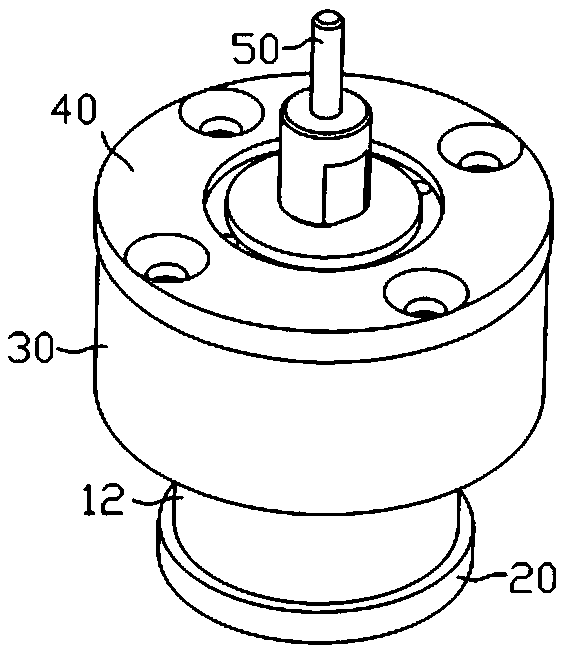

[0026] combine figure 1 , figure 2 , a kind of cleaning disc brush, described cleaning disc brush comprises cylindrical part 10, the dish-shaped sponge 20 that is close to the bottom end surface of cylindrical part, the cleaning cloth that wraps disc-shaped sponge and the bottom of cylindrical part, is sleeved on cylindrical part The outer cylindrical part 30 on the top, the cover plate 40 fixedly connected with the top surface of the outer cylindrical part, and the shaft 50 fixedly installed on the top surface of the cover plate.

[0027] Described cylindrical member comprises large-diameter section 11, the small-diameter section 12 of external diameter smaller than large-diameter section, and described disc-shaped sponge is close to the bottom end surface of small-diameter section, and described cleaning cloth is wrapped in disc-shaped sponge and small-diameter section The bottom of the outer cylinder part is provided with a protruding annular ring 31 inside, the small-dia...

no. 2 example

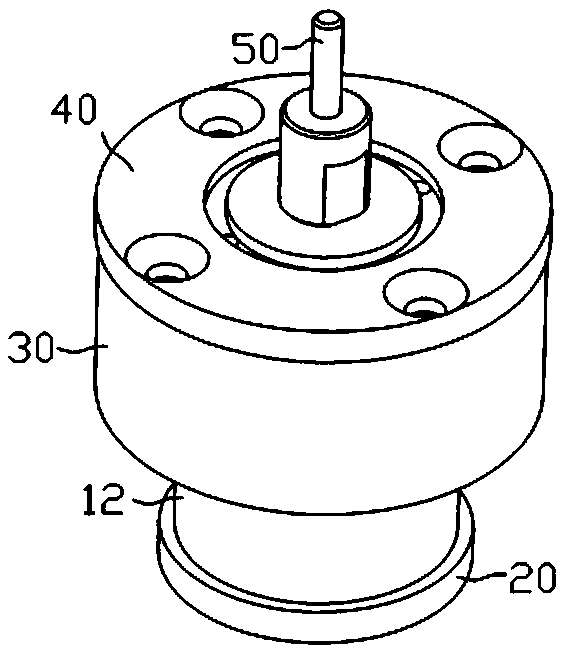

[0032] combine image 3 , Figure 4 , a kind of cleaning disc brush, described cleaning disc brush comprises cylindrical part 10, the dish-shaped sponge 20 that is close to the bottom end surface of cylindrical part, the cleaning cloth that wraps disc-shaped sponge and the bottom of cylindrical part, is sleeved on cylindrical part The outer cylindrical part 30 on the top, the cover plate 40 fixedly connected with the top surface of the outer cylindrical part, and the shaft 50 fixedly installed on the top surface of the cover plate.

[0033] Described cylindrical member comprises large-diameter section 11, the small-diameter section 12 of external diameter smaller than large-diameter section, and described disc-shaped sponge is close to the bottom end surface of small-diameter section, and described cleaning cloth is wrapped in disc-shaped sponge and small-diameter section The bottom of the outer cylinder part is provided with a protruding annular ring 31 inside, the small-dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com