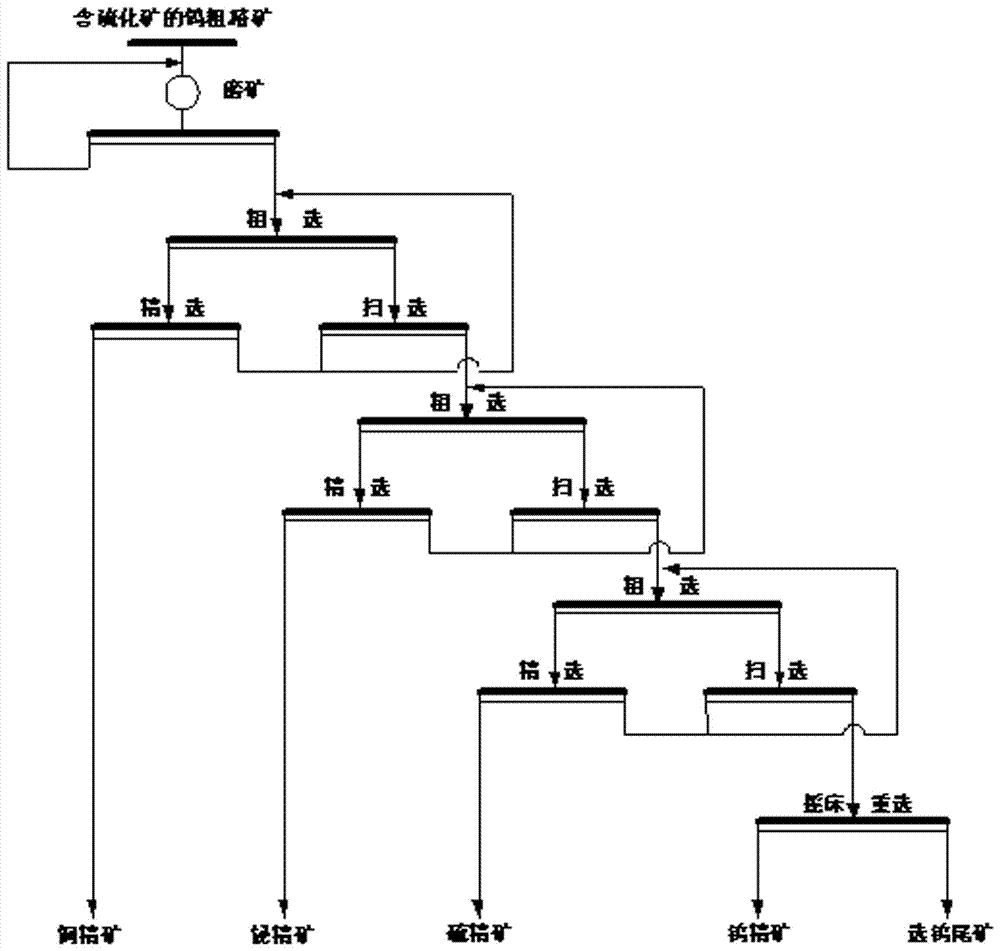

Method for recovering valuable metals from tungsten rough concentrate containing sulfide ore

A technology for valuable metals and rough concentrates, applied in chemical instruments and methods, wet separation, solid separation, etc., to achieve the effects of reducing sulfur content, optimizing chemical system and process flow, and improving recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]The ore feed is tungsten ore associated with sulfide ore in a certain place in northern Guangdong. The associated sulfide ore is mainly copper, bismuth, sulfur, etc. After obtaining tungsten coarse concentrate containing sulfide ore through jigging and shaking table, the sulfide-containing Grind the tungsten coarse concentrate of the ore until the particle size is -0.074mm, accounting for 79%, add water to the slurry concentration of 35%, add quicklime to adjust the pH to 12; add collector Z-200 150g / t, stir for 2 minutes, and make coarse Sweeping, to obtain roughing copper concentrate and roughing copper tailings; add collector Z-200 40g / t to the roughing copper tailings, stir for 3 minutes, do sweeping, get sweeping copper concentrate and sweeping copper Tailings; Sweep copper concentrate and return to copper roughing operation; add inhibitor quicklime 1000g / t to rough copper concentrate, adjust pH to 12, stir for 3 minutes, add collector Z-20020g / t, Stir for 2 minutes...

Embodiment 2

[0035] The ore supply is tungsten ore associated with sulfide ore in a certain place in Jiangxi. The associated sulfide ore is mainly copper, bismuth, sulfur, etc. After obtaining tungsten rough concentrate containing sulfide ore through jigging, the tungsten rough concentrate containing sulfide ore Grind the ore until the particle size is -0.074mm, accounting for 85%, add water until the slurry concentration is 33%, add quicklime to adjust the pH to 12.5; add collector Z-200 130g / t, stir for 2 minutes, and do roughing to obtain Rough separation of copper concentrate and rough separation of copper tailings; add collector Z-200 30g / t to the rough separation of copper tailings, stir for 3 minutes, and do scavenging to obtain scavenging copper concentrates and scavenging copper tailings Sweep copper concentrate and return to copper roughing operation; add inhibitor quicklime 800g / t to rough copper concentrate, adjust slurry pH to 11, stir for 3 minutes, add collector Z-200 30g / t, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com