Coke-oven gas methanation catalyst and preparation method and application thereof

A catalyst, gas methane technology, applied in the field of coke oven gas methanation catalyst and its preparation, can solve the problems of poor thermal stability, unexplained overall effect of methanation catalyst, etc., achieve high temperature hydrothermal stability and broad, active Effect of wide temperature range and enhanced dispersion function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

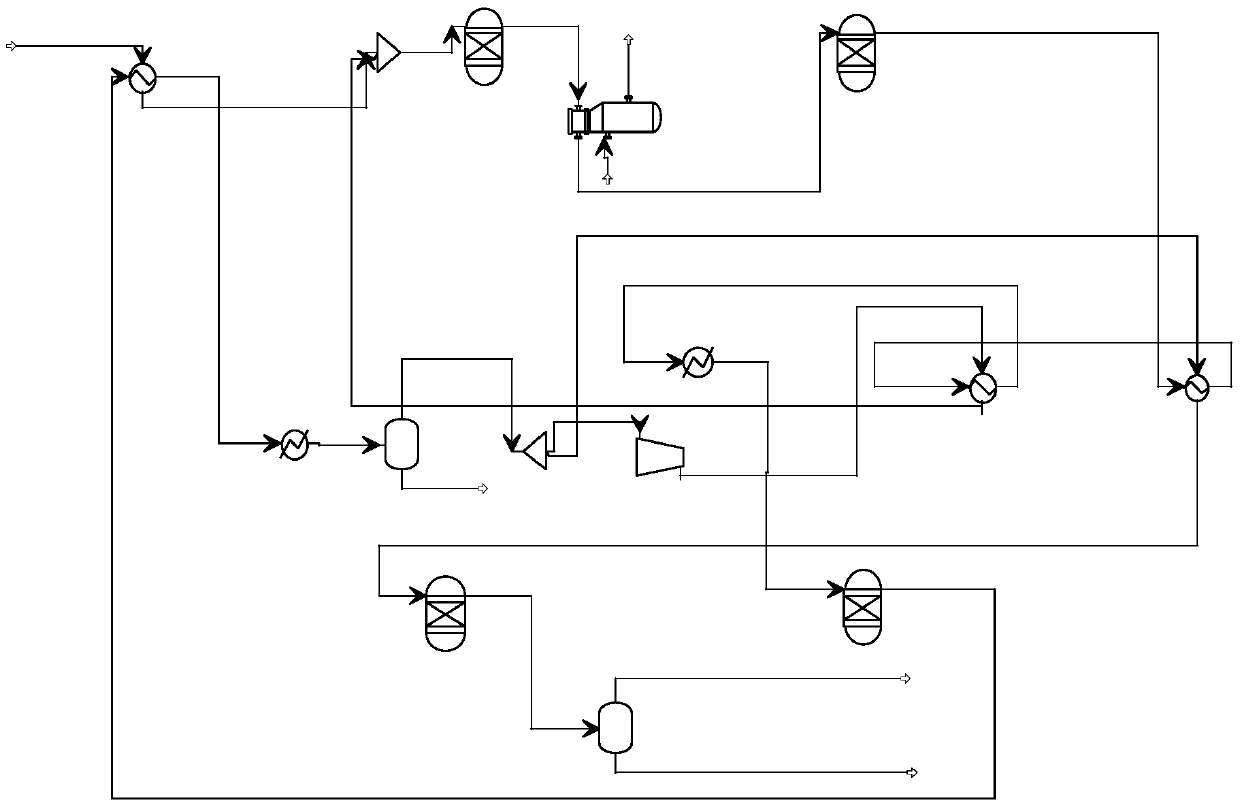

Image

Examples

Embodiment 1

[0032] This example is used to illustrate the preparation method of the complete methanation catalyst provided by the present invention.

[0033] (1) Weigh 52.3458 grams of Ni (NO 3 ) 2 ·6H 2 O, 5.19612 g La(NO 3 ) 3 ·6H 2 O, 10.30138 g Zr(NO 3 ) 4 ·5H 2 O, 9.25708 g Ca(NO 3 ) 2 4H 2 O, 6.15384 g Mg(NO 3 ) 2 .6H 2 O and 194.3935 g Al(NO 3 ) 3 9H 2 O, dissolved in 400ml deionized water at 70°C to obtain solution I;

[0034] (2) Weigh 92.1269 grams of Na 2 CO 3 and 36.5065 g NaHCO 3 , was dissolved in 400ml of deionized water at 70°C, and 60ml of 10wt% polyvinyl alcohol solution was added to the solution to obtain solution II.

[0035] (3) Measure 200ml of deionized water in a beaker and heat it to 70°C in a 30Hz frequency ultrasonic heater. Under stirring, solution I and solution II were added into the 200ml of deionized water in parallel flow to carry out neutralization and precipitation reaction, and the pH of the reaction system was controlled to be 7.5-8....

Embodiment 2

[0039] The solution preparation and preparation process was similar to that of Example 1, except that the amount of polyvinyl alcohol solution added in step (2) was 30 ml, and the prepared methanation catalyst was denoted as A2.

Embodiment 3

[0041] The solution preparation and preparation process was similar to that of Example 1, except that the amount of polyvinyl alcohol solution added in step (2) was 90 ml, and the prepared methanation catalyst was designated as A3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com