Tail gas recovery system for naphthalene water reducer

A technology of naphthalene-based water reducer and tail gas recovery, which is applied in gas treatment, membrane technology, and separation of dispersed particles. It can solve the problems of strong acidity of sulfuric acid volatiles, corrosion of production equipment, and increase of production costs. The effect of reducing raw material costs and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

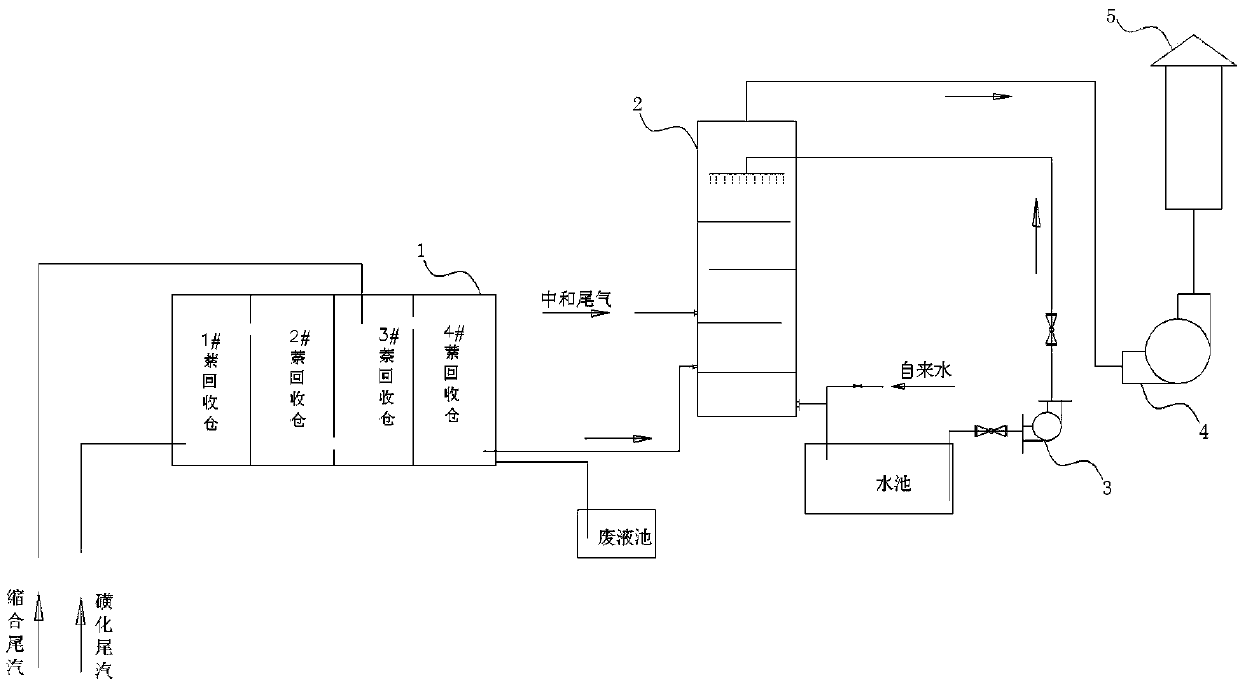

[0021] like figure 1 As shown, a tail gas recovery system for naphthalene-based water reducers includes a closed naphthalene recovery room 1, a waste liquid pool, a closed spray tower 2, a water pool, a fan 4 and a chimney 5, and the naphthalene recovery room 1 is connected to the waste water through pipelines. The liquid pool is connected to the spray tower 2, the top of the spray tower 2 is connected to the blower fan 4 and the chimney 5 through pipelines in turn, and the bottom is connected to the water pool through pipelines, and the naphthalene recovery room 1 is respectively provided with the condensation tail gas and the sulfonation tail gas. Pipeline, spray tower 2 is provided with the pipeline that leads into neutralization tail gas.

[0022] The fan 4 plays the role of ensuring the tail gas flow in the system and maintaining the normal pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com