An integrated device for follow-up locking and automatic unlocking

An automatic unlocking and follow-up technology, applied in the direction of the antenna support/installation device, etc., can solve the problems of cumbersome and fragmented operation steps, extremely high matching accuracy requirements, and many positioning components, etc., to improve the efficiency of erection and retraction, and the matching accuracy. Low requirements, high working reliability and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

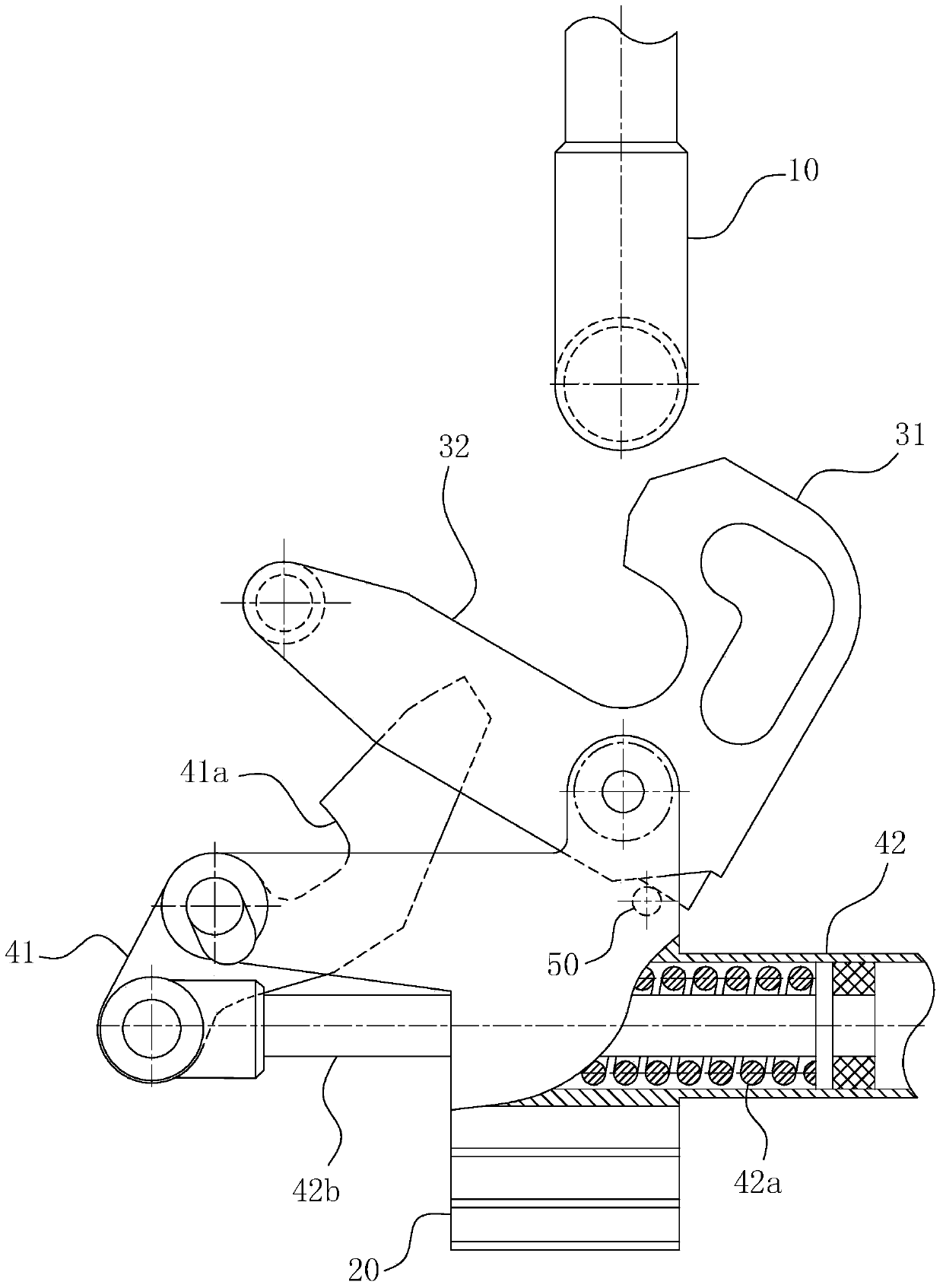

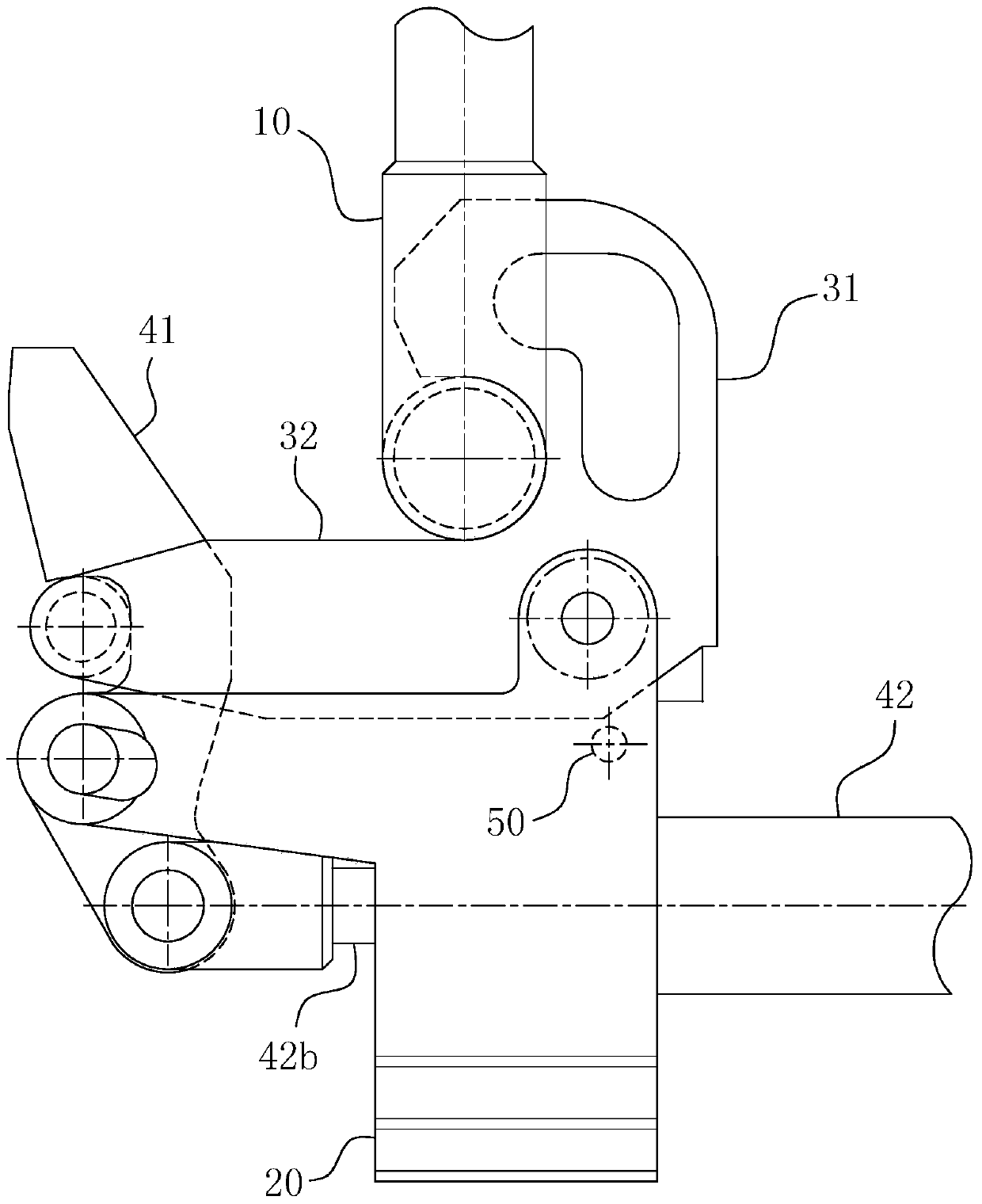

[0023] For ease of understanding, here in conjunction with accompanying drawing, specific implementation structure and work flow of the present utility model are described as follows:

[0024] Concrete structure of the present invention, as Figure 1-2 As shown, it includes a locking rod 10 fixed on the antenna to be locked by welding or other means, and a locking seat 20 for performing follow-up locking and automatically unlocking the above-mentioned locking rod 10 . The locking seat 20 is provided with the following locking components: the power part 42 formed by the combination of the one-way oil cylinder and the compression spring 42a, the seesaw 41 hinged with the piston rod 42b of the power part 42, and the positioning notch on the seesaw 41 41a is a torsion spring hinged lock hook that fits in place; the axes of the above-mentioned hinged parts are all parallel to each other. During design, the torsion spring hinged lock hook is composed of the hook body 31, the hook h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com