Assembling technology for metal cover board and cavity component of cavity filter

A cavity filter and metal cover technology, which is applied to waveguide-type devices, electrical components, circuits, etc., can solve the problem of poor sealing between metal cover and cavity components, reduced electrical performance and stability of devices, and metal cover. It can solve problems such as many holes in the cavity and many other problems, so as to achieve the effect of unaffected electrical performance and stability, release of processing stress and assembly stress, and improvement of market competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

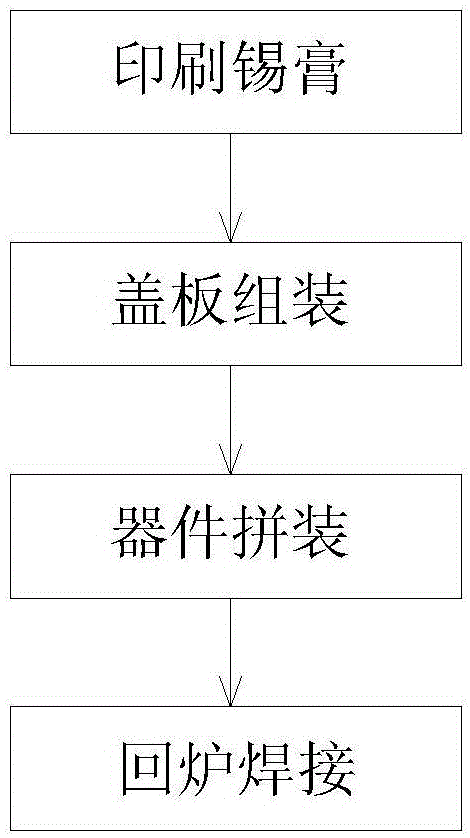

[0027] Such as figure 1 As shown, the assembly process of the metal cover plate of the cavity filter and the cavity component includes the following steps:

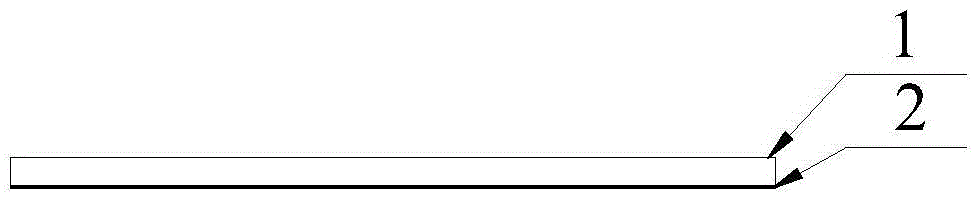

[0028] (1) Printing solder paste, such as figure 2 As shown, the metal cover 1 is fixed and positioned on the printing machine, and a layer of low-temperature solder paste 2 with a thickness of 0.18 mm is printed on the predetermined installation position of the metal cover 1 and the cavity assembly 5 through a stencil.

[0029] Specifically, the low-temperature solder paste 2 is a SnBiAg-based solder paste with a melting point of 142°C.

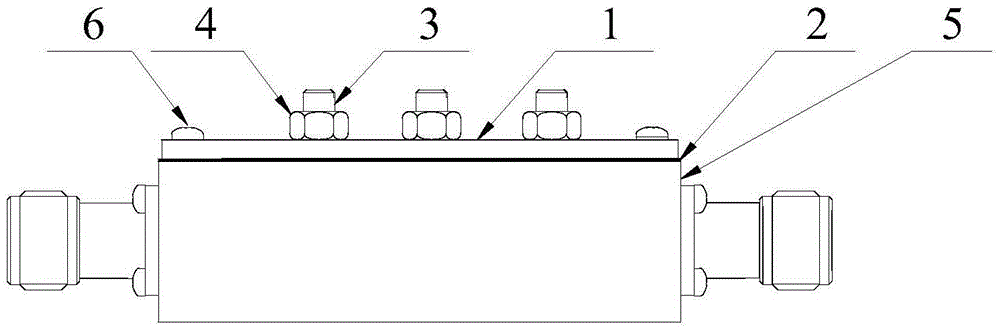

[0030] (2) Assemble the cover, assemble the tuning screw 3 and the tuning nut 4 with the metal cover 1 .

[0031] Specifically, according to the needs, the tuning screw 3 and the tuning nut 4 are installed in the corresponding position of the met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com