Prediction function control method for coking heating furnace oxygen content

A technology for predicting function control and oxygen content, applied in the field of automation, can solve the problems of coke ovens limiting the applicability and efficiency of DMC control, interference, and affecting oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Take the oxygen content control process in the coking heating furnace as an example:

[0066] 1. Establish the model of the coking furnace

[0067] 1-1. Since the oxygen content in the coking furnace can be described as two parts, linear and nonlinear, the following expression can be obtained:

[0068] y(k)=y L (k)+y NL (k)(1)

[0069] where y L (k) is the output of the model under the step response, y NL (k) is through y L (k) and y(k)| i ,(i=1,2,…,N) The nonlinear module determined by the deviation between, y(k)| i , (i=1,2,...,N) is the output of the controlled object output y(k) in the actual process at time i, and N is the number of output sampling points.

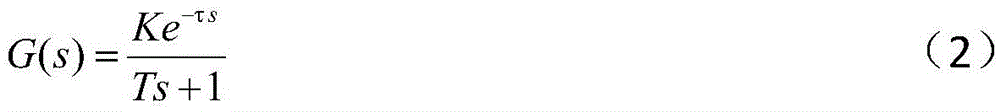

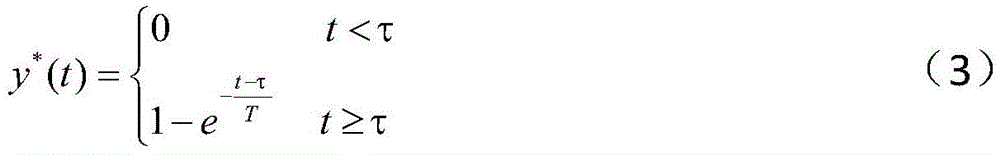

[0070] 1-2. The linear part of the model can be obtained by step response, y(t) is the actual output of the model, y(∞) is the steady-state output of the model, U 0 is the magnification of the input signal. The output y(t) can be used Expressed in the form of , the gain of the model can be expressed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com