Heat radiator capable of enhancing core strength and lowering oil leakage rate

A technology to strengthen cores and radiators, applied to heat exchanger types, heat exchanger shells, indirect heat exchangers, etc., can solve problems such as large cores, oil leakage, welding deformation, etc., to prevent deformation and reduce oil leakage rate, increase the effect of seismic strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

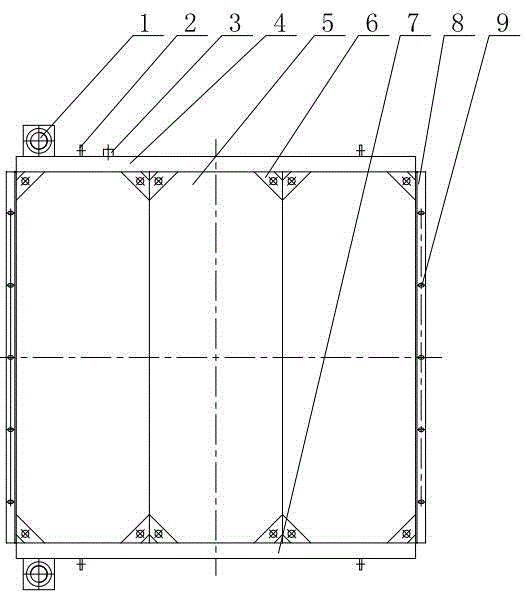

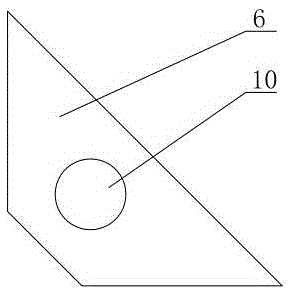

[0017] Such as figure 1 As shown, the radiator of the present embodiment that strengthens the strength of the core body and reduces the oil leakage rate includes a large core body composed of a plurality of core bodies 5, and an upper head 4 is installed on the top of the large core body, and is located at the top of the large core body. The bottom of the upper head 7 is installed with the lower head 7, the left ends of the upper head 4 and the lower head 7 are respectively equipped with input joints 1, and the two ends of the upper head 4 and the lower head 7 are respectively installed with lifting lugs 2, which are located at the two lifting lugs. The top of the upper head 4 between 2 is equipped with an output joint 3; the left and right ends of the large core body are respectively equipped with angle aluminum 8, and the angle aluminum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com