Modular passenger car gas catalytic flameless infrared radiation heating fast drying chamber

A gas-catalyzed and fast drying technology, applied in the field of drying chambers, can solve problems such as affecting production progress, high operating costs, and low thermal efficiency, and achieve the effect of ensuring production progress and surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

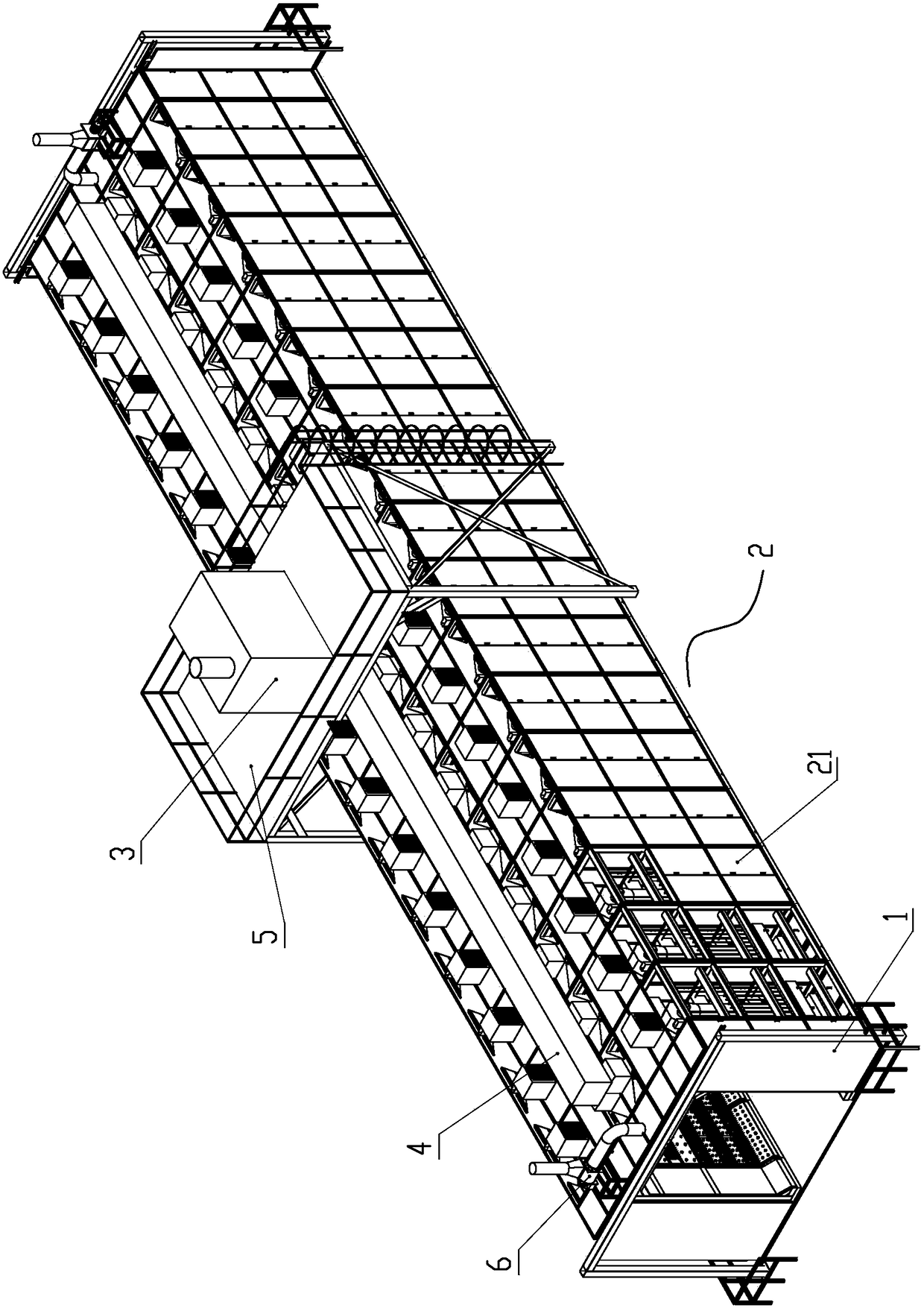

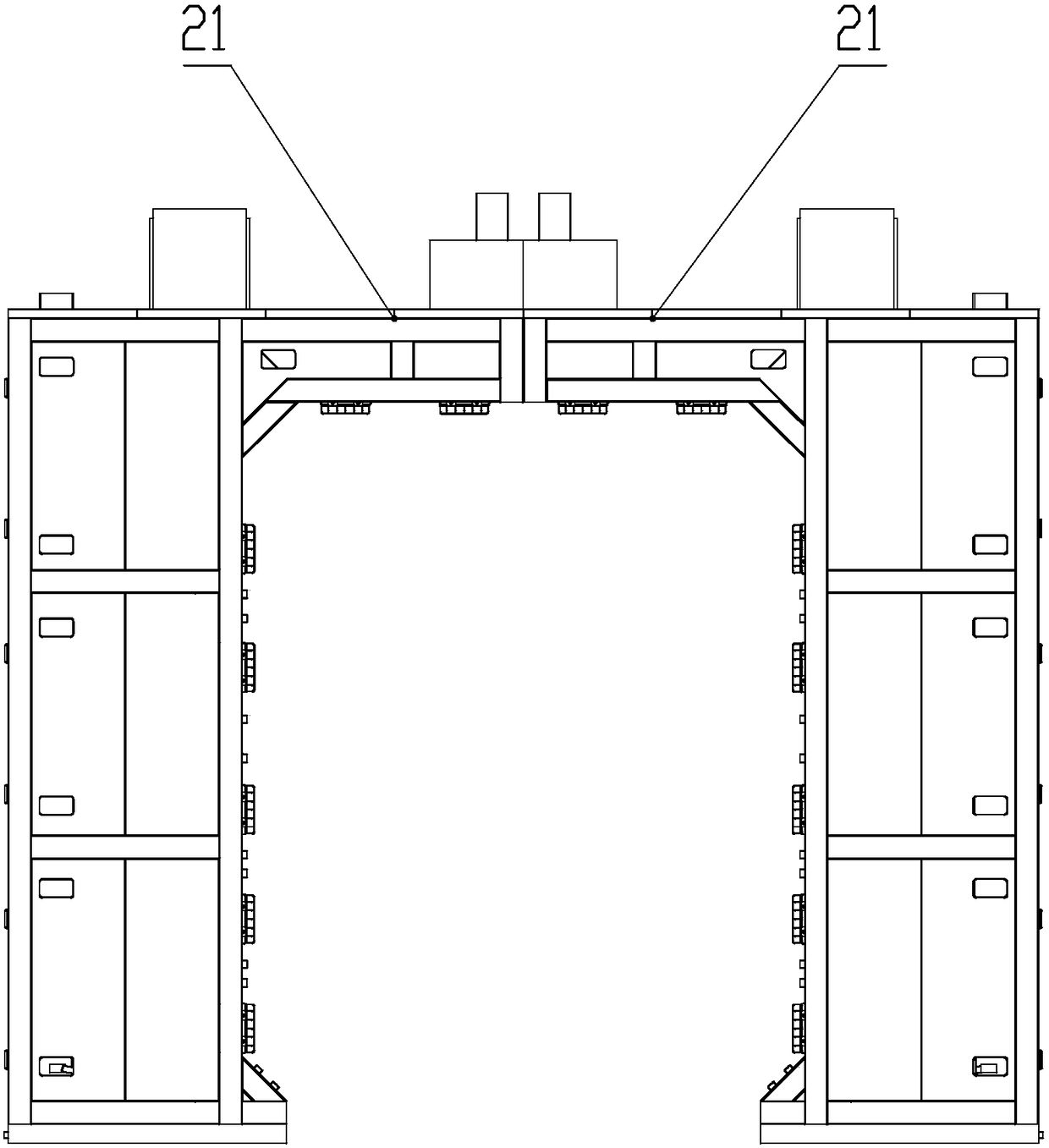

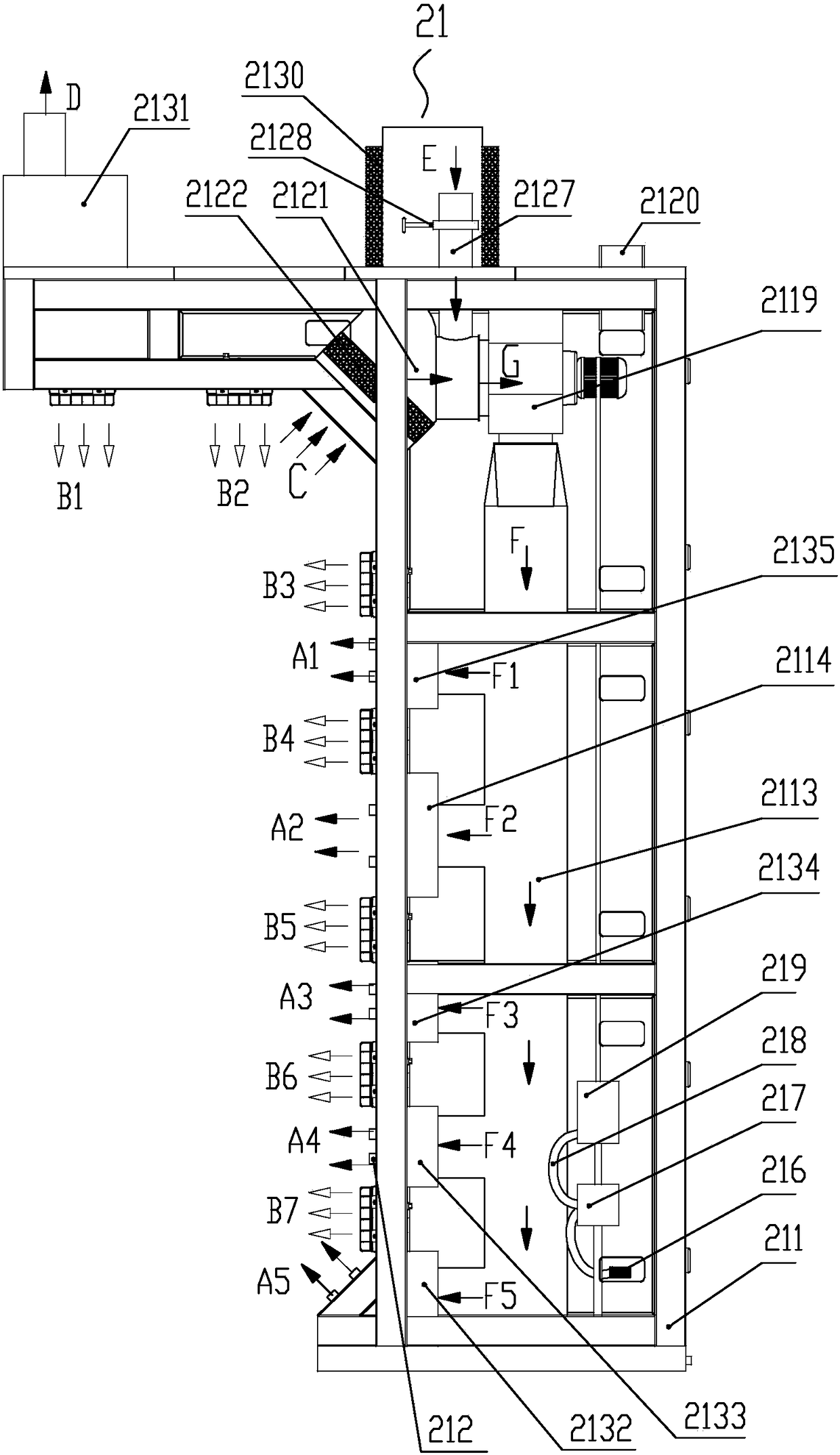

[0083] A modular passenger car gas catalytic flameless infrared radiation heating fast drying chamber (see figure 1), including the drying chamber door 1 and the drying chamber body 2, the drying chamber door 1 is installed at the entrance and exit of the drying chamber body 2, the drying chamber door 1 is a thermal insulation electric double door, and the drying chamber body 2 The entrance and exit of the entrance and exit are also equipped with an entrance and exit exhaust system 6. The drying chamber body 2 is formed by connecting multiple sets of door-type fast drying unit modules, and each group of door-type fast drying unit modules is composed of two symmetrically arranged passenger car gas catalytic flameless infrared radiation hot air The circulating drying unit modules 21 are connected (see figure 2 ); the top of each passenger car gas catalytic flameless infrared radiation hot air internal circulation drying unit module 21 is also connected to the exhaust gas treat...

Embodiment 2

[0105] A modular passenger car gas catalytic flameless infrared radiation heating fast drying room, the drying room is basically the same as the first embodiment, the difference is: in the gas catalytic flameless heating VOC treatment system, the gas catalytic flameless infrared radiation Three sets of heating catalytic combustion devices of the heating catalytic processor 34 are arranged in a U shape (see Figure 9 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com