Gas exhaust valve drive system with stroke capable of being compensated and regulated

A technology for compensating, adjusting, and driving the system. It is applied to the components of the fluid pressure actuation system, valve details, valve devices, etc. It can solve the problems of small degree of freedom in exhaust control, different air exchange quality, and impact on the performance of diesel engines. cost, solve consistency problems, improve the effect of freedom of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The stroke compensation adjustable exhaust valve driving system of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but this should not limit the protection scope of the present invention.

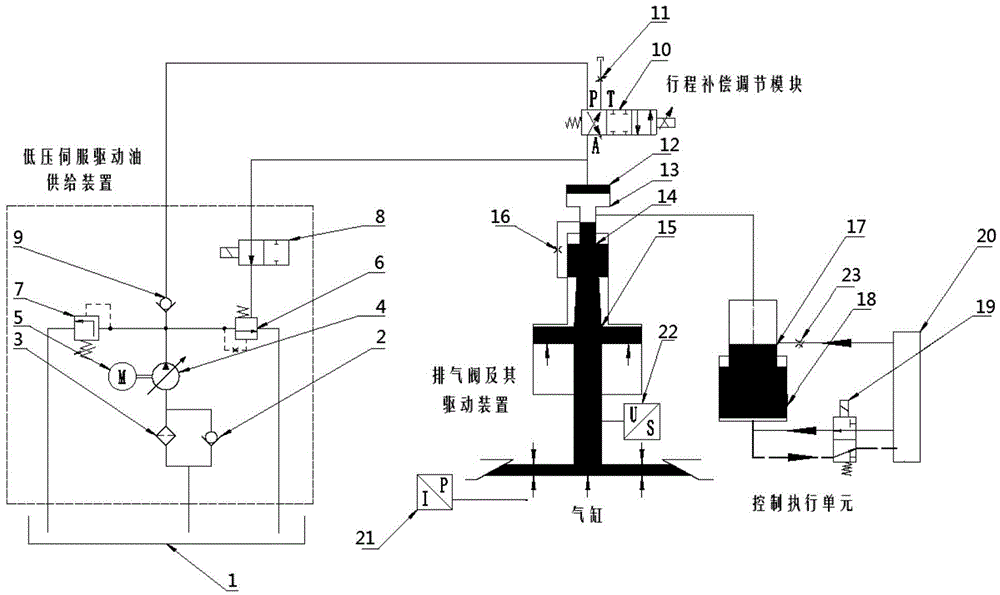

[0029] see figure 1 , The exhaust valve driving system with adjustable stroke compensation in the present invention includes a low-pressure servo drive oil supply device, a stroke compensation adjustment module, a high-pressure common rail unit 20, a control execution unit, an exhaust valve and its driving device.

[0030] The low-pressure servo drive oil supply device is connected to the stroke compensation adjustment module and provides low-pressure servo drive oil with stable pressure and adjustable load sensitivity to the stroke compensation adjustment module. The low-pressure servo drive oil supply device includes an oil tank 1, a check valve 2, a filter 3, a variable displacement pump 4, a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com