Dual-layer compound seal blocking mechanism

A double-layer composite, plugging disk technology, applied in the direction of engine sealing, fluid tightness testing, machine/structural component testing, etc. Achieve the effect of improving flexibility, large renovation space, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

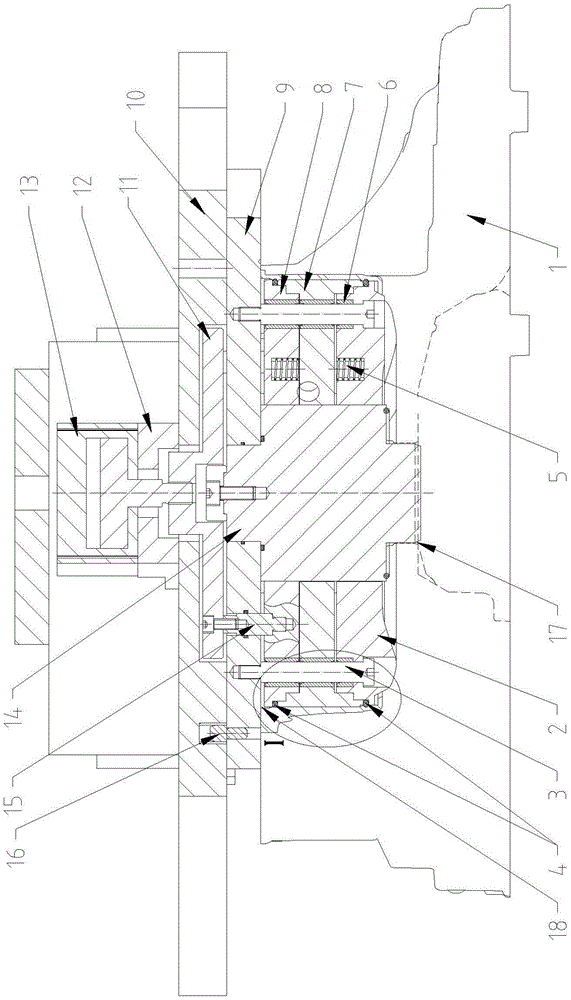

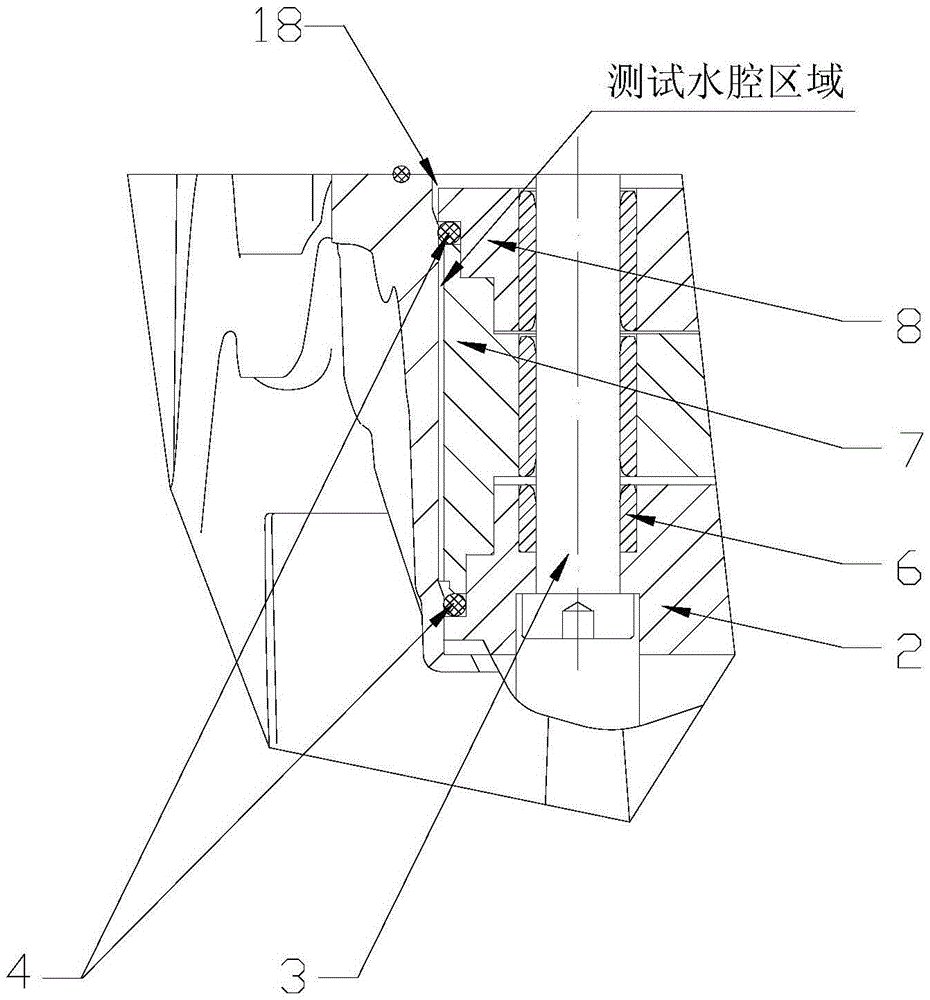

[0020] Such as figure 1 and figure 2 As shown, this embodiment includes: a clamping cylinder part, a blocking plate 9, an upper blocking disk 8, a lower blocking disk 2 and an intermediate disk 7, wherein: the clamping cylinder part is fixedly connected with the upper blocking disk 8, and the sealing The blocking plate 9 is arranged between the clamping cylinder part and the upper blocking plate 8;

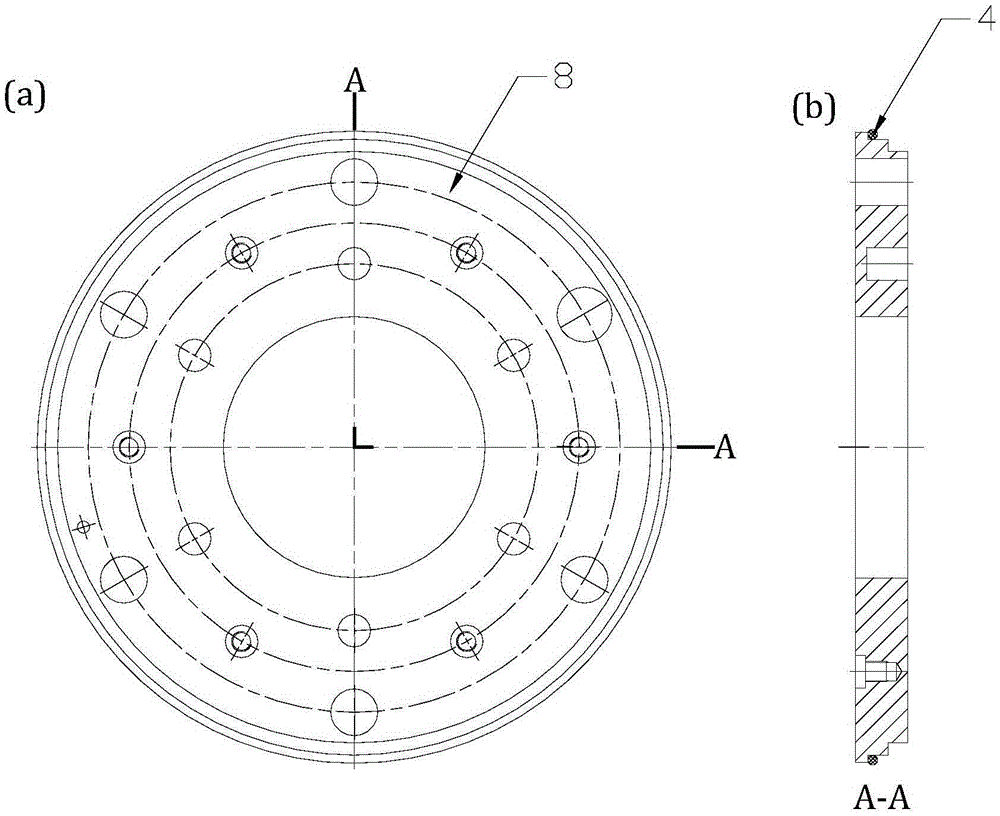

[0021] The upper blocking disk 8, the lower blocking disk 2 and the intermediate disk 7 are elastically connected by a balance spring 5, and there is a clearance fit between the intermediate disk 7 and a sealing ring 4, and the upper and lower sealing rings 4 After compression and expansion, the test water tank area is formed with the inner wall of the housing 1 .

[0022] The clamping oil cylinder part includes: an oil cylinder 13, an oil cylinder base 12 and a connection plate 11 connected in sequence, wherein: the oil cylinder 13 is arranged on the oil cylinder base 12 and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com