An adjustable two-way mechanical clamping tool

A mechanical clip and adjustable technology, applied in the field of tooling fixtures, can solve the problems of parts misalignment, tape fixing cannot be used as a long-term stable fixing solution, and cannot meet precise positioning, etc., to achieve low processing costs, stable assembly and fixing effects, and stable and firm fixing effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

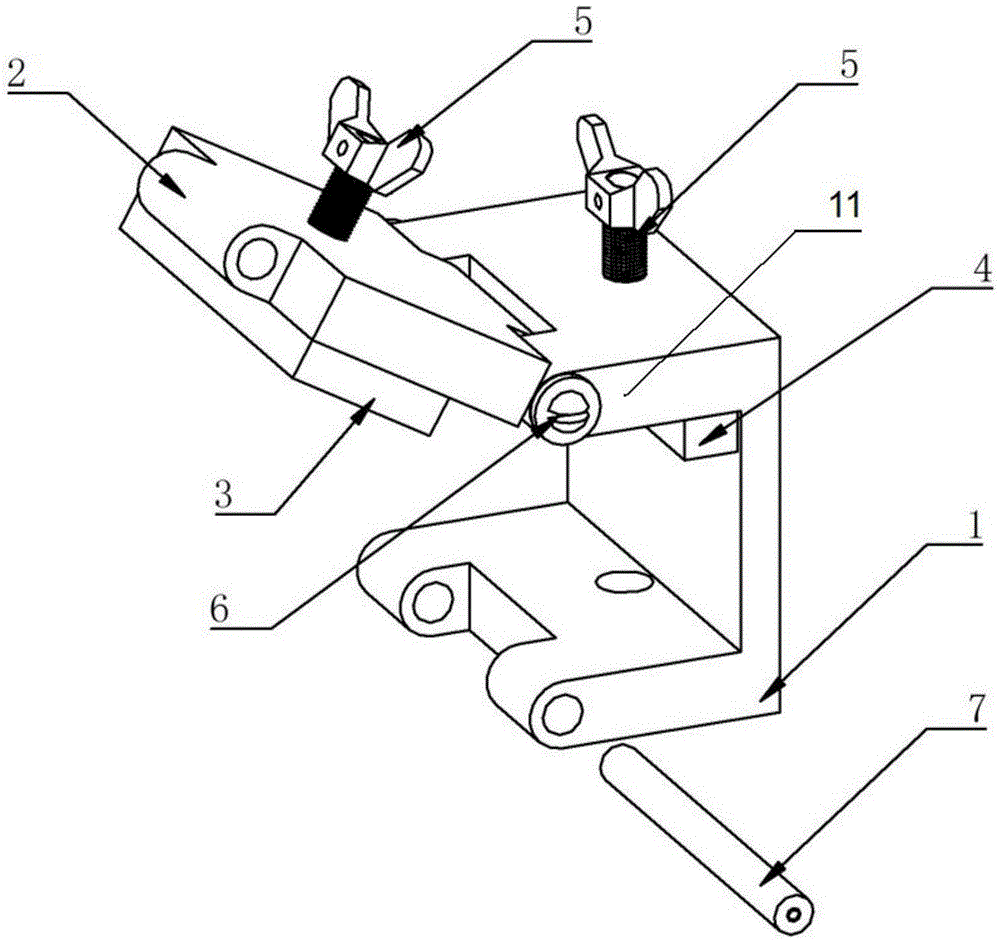

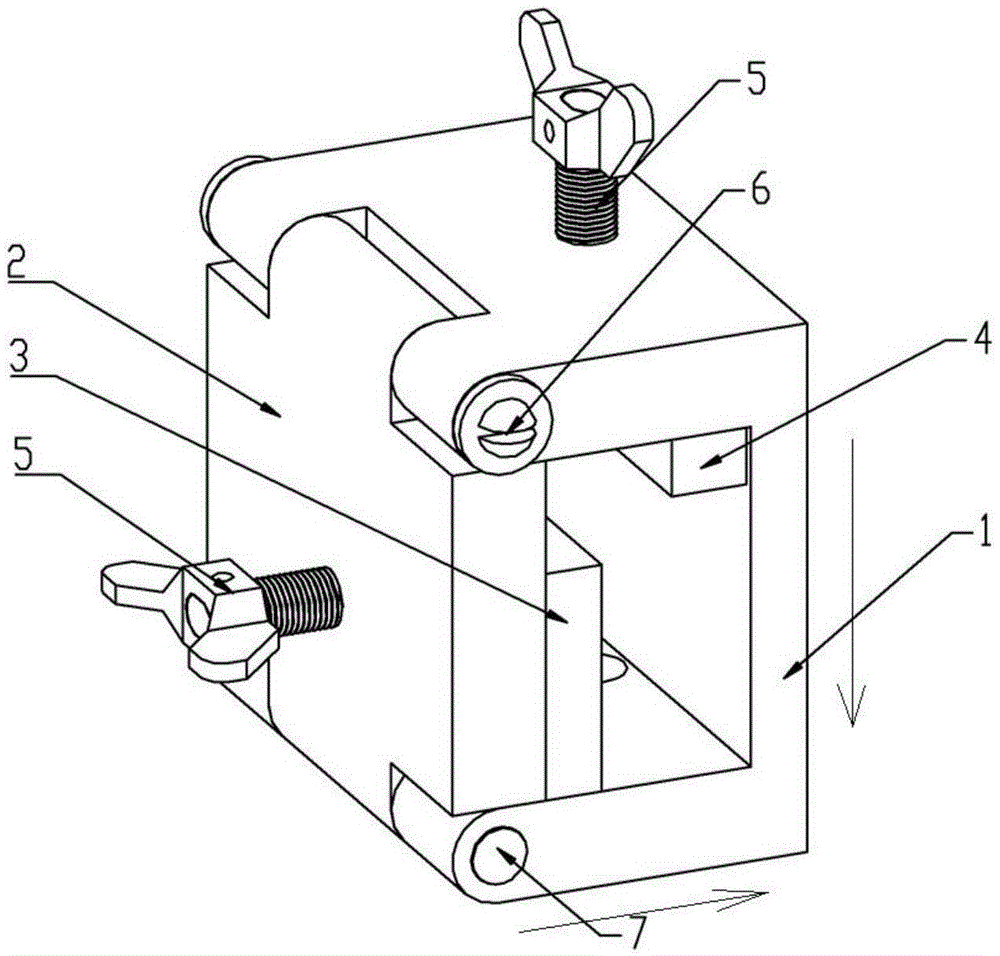

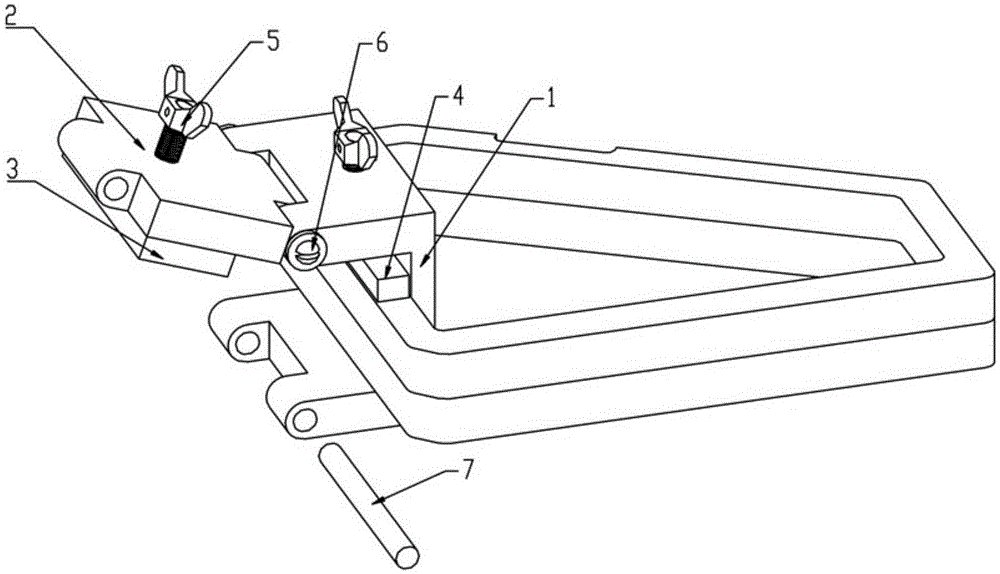

[0022] Figure 1~4 It is a structural schematic diagram of an adjustable two-way mechanical clamping tooling of the present invention, which includes a clamping body 1 and a rotating baffle 2. The clamping body 1 is a groove-shaped structure, and one end of the rotating baffle 2 and the opening end of the clamping body 1 pass a positioning screw 6 is hinged, the other end of the rotating baffle 2 and the other end of the opening of the clamp body 1 are detachably connected by a pin 7;

[0023] The side plate of the clamp body 1 is provided with an adjusting screw 5, the adjusting screw 5 on the side plate is perpendicular to the side plate, the adjusting screw 5 is threadedly connected with the side plate, and the end of the adjusting screw 5 is movably connected with the lateral pressure plate 4 and the adjusting screw 5. A groove is provided at the end, and the groove is matched with the lateral pressure plate 4 and limits the position of the lateral pressure plate 4 in the axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com