Self-propelled stamping slurry extracting spiral calendaring canal lining machine

A self-propelled, lining machine technology, applied in artificial waterways, water conservancy projects, construction, etc., can solve the problems of low mechanization degree and work efficiency, low mechanization degree, and the need for manual plastering, so as to save manpower, improve construction quality, and eliminate The effect of quality hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

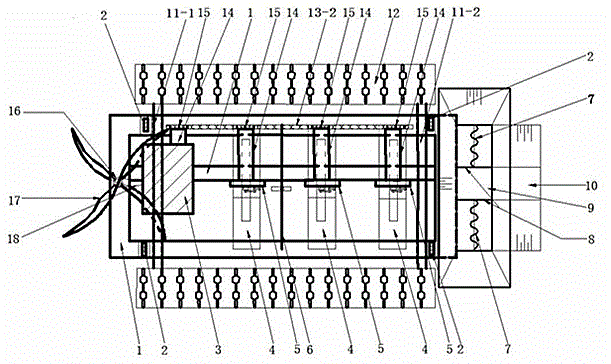

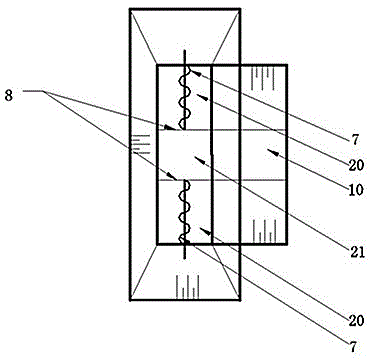

[0018] See Figure 1~6 , the specific structure is as follows:

[0019] The lining machine of this embodiment is designed according to the standard section of the channel with a bottom width of 0.3m, a side slope of 1:1, and a depth of 0.45m.

[0020] See figure 1 , 2 , the main frame 1 that can be lifted is located on the crawler travel mechanism, and the specific structure is: the drive shaft 11-1 and the driven shaft 11-2 of the crawler travel mechanism are respectively assembled with the drive wheel 19-1 and the driven wheel 19-2 of the travel device, The crawler belt 12 is assembled on the two wheels; the motor reduction device 3 drives the drive shaft 11-1 through the transmission chain 13-1, the driving wheel 19-1 and the driven wheel 19-2 rotate, and the crawler belt 12 advances.

[0021] The four corners of the main frame 1 are threadedly connected with the lifting adjustment screw 2 with the operating handle; the shaft sleeve A is assembled through bearings on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com