Coal mine paste filling material using construction waste and its preparation and filling method

A technology for filling materials and construction waste, applied in the fields of filling materials, mining equipment, earth-moving drilling, etc. Strict and scientific grading, prolonged pumping time and improved filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

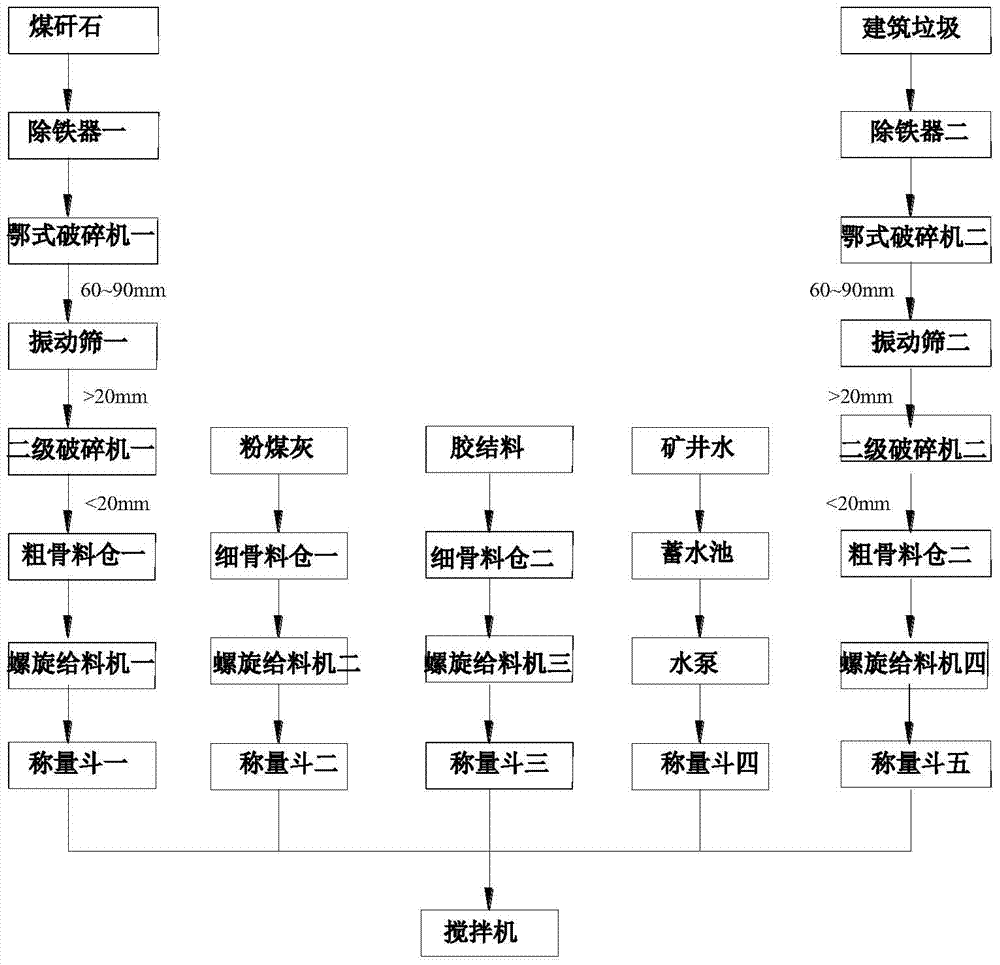

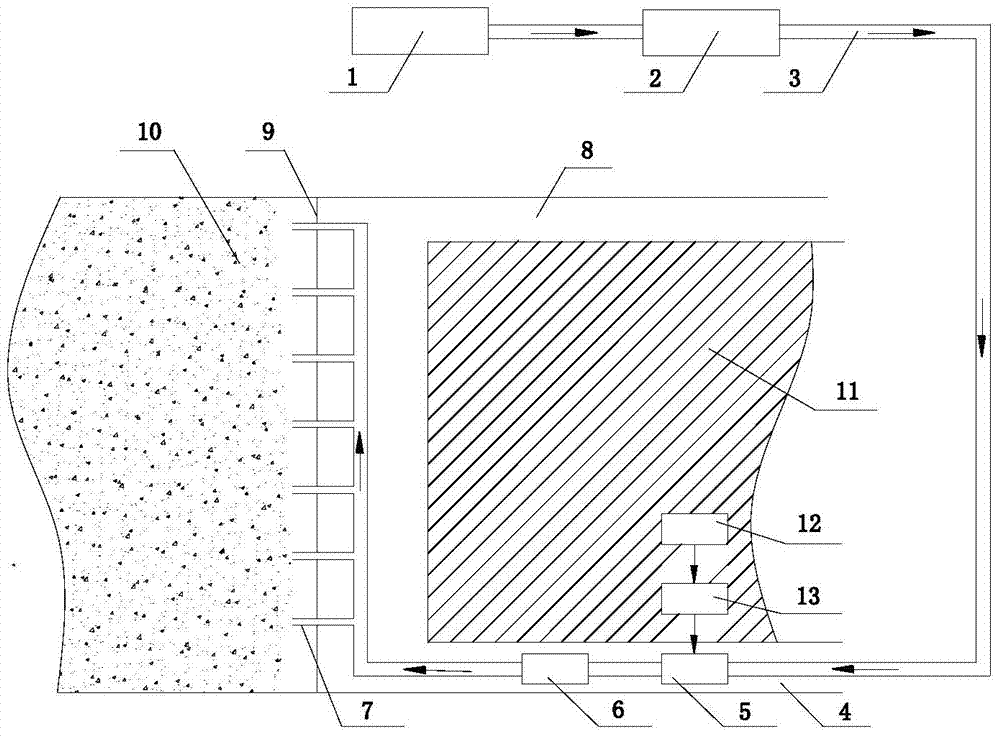

Method used

Image

Examples

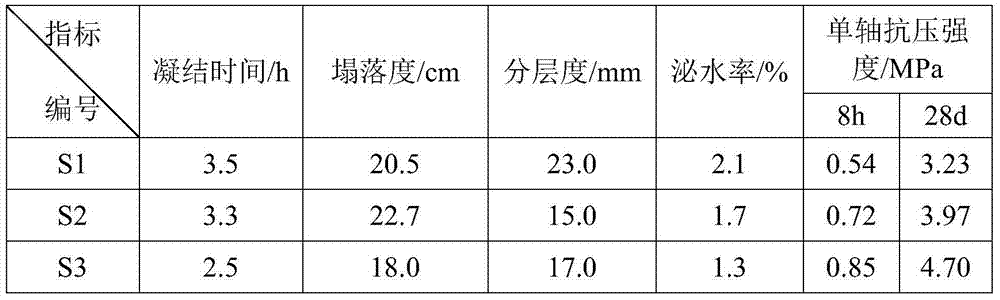

Embodiment 1

[0033] A coal mine-like paste filling material using construction waste, every 1m 3 The filling material is composed of the following raw materials: coarse aggregate: construction waste 500Kg and coal gangue 450Kg, fine aggregate: fly ash 400Kg and cementing material 250Kg, admixture: accelerator 12.5Kg and water reducer 7.5Kg, mine water 630Kg.

[0034] The construction waste refers to waste concrete blocks, waste sand, waste bricks and tiles, waste stones, ceramic fragments and waste tiles with a particle size of less than 20mm after secondary crushing due to building construction, decoration and demolition. 4.32% are 16mm-20mm, 3.66% are 13.5mm-16mm, 10.82% are 9.5mm-13.5mm, 21.51% are 5mm-9.5mm, and 1mm ~5mm accounted for 29.05%, particle size 0.3mm~1mm accounted for 14.89%, particle size 0.1mm~0.3mm accounted for 8.76%, particle size 0.075mm~0.1mm accounted for 2.34%, 0~0.075mm 4.65%;

[0035] The coal gangue is raw coal mine gangue waste with a particle size of less t...

Embodiment 2

[0048] A coal mine-like paste filling material using construction waste, the filling material per 1m3 is composed of the following raw materials: coarse aggregate: 475Kg of construction waste and 425Kg of coal gangue; fine aggregate: 375Kg of fly ash and cemented Material 225Kg; Additives: Accelerator 9.5Kg and Water Reducer 5.5Kg; Mine Water 630Kg.

[0049] The construction waste refers to waste concrete blocks, waste sand and stones, waste bricks and tiles, waste stones, ceramic fragments and waste ceramic tiles with a particle size of less than 20mm after secondary crushing due to building construction, decoration and demolition. 5% for 16mm-20mm, 2% for 13.5mm-16mm, 15% for 9.5mm-13.5mm, 25% for 5mm-9.5mm, 1mm ~5mm accounted for 25%, particle size 0.3mm~1mm accounted for 15%, particle size 0.1mm~0.3mm accounted for 6%, particle size 0.075mm~0.1mm accounted for 5%, 0~0.075mm 2%;

[0050] The coal gangue is raw coal mine gangue waste with a particle size of less than 20mm ...

Embodiment 3

[0060] A coal mine-like paste filling material utilizing construction waste, the filling material per 1m3 is composed of the following raw materials: coarse aggregate: 450Kg of construction waste and 400Kg of coal gangue; fine aggregate: 350Kg of fly ash and cemented Material: 200Kg; Additives: Accelerator 6.0Kg and Water Reducer 2.0Kg; Mine Water 550Kg.

[0061] The construction waste is waste concrete blocks, waste sand, waste bricks and tiles, waste stones, ceramic fragments and waste tiles with a particle size of less than 20 mm after secondary crushing due to construction, decoration and demolition, wherein the particle size is 16mm~20mm accounted for 1%, particle size 13.5mm~16mm accounted for 5%, particle size 9.5mm~13.5mm accounted for 10%, particle size 5mm~9.5mm accounted for 20%, particle size 1mm~ 5mm accounted for 35%, particle size 0.3mm~1mm accounted for 10%, particle size 0.1mm~0.3mm accounted for 10%, particle size 0.075mm~0.1mm accounted for 4%, 0~0.075mm acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com