A preparation method of single-layer close-packed nano-microsphere array

A technology of nano-microspheres and close-packing, which is applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of high price and easy damage to the template layer close-packing structure by motors, and achieve low cost, simple structure, and liquid level small perturbation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1)硅片清洗:将10mm×15mm的Si(100)基片依次放在去离子水中超声清洗10min,在甲苯中超声10min,在去离子水中超声清洗5min,在丙酮中超声10min,在去离子水中超声清洗5min,在乙醇中超声10min,在去离子水中超声清洗5min;配制硫酸(97%)、双氧水(30%)体积比为3∶1的溶液,将硅片放在溶液中并在80℃下超声2h,然后取出在去离子水中超声清洗3次,每次5min;配制氨水(28%)、双氧水(30%)、去离子水按体积比1∶1∶5混合的溶液,将硅片放在溶液中并在80℃下超声2h,再在去离子水中超声清洗10min;再把硅片放置到SDS(四氢呋喃,10%浓度)溶液里浸泡12h,增加亲水性。取出在去离子水中超声清洗3次,每次5min。上述超声机工作功率100W,频率40kHz。

[0036] 2)玻片清洗:将10mm×15mm的玻片依次放在去离子水中超声清洗10min,在甲苯中超声10min,在去离子水中超声清洗10min,在丙酮中超声10min,在去离子水中超声清洗10min,在乙醇中超声10min,在去离子水中超声清洗10min。同样再把玻片放置到SDS(10%浓度)溶液里浸泡12h,增加亲水性。取出在去离子水中超声清洗3次,每次5min。

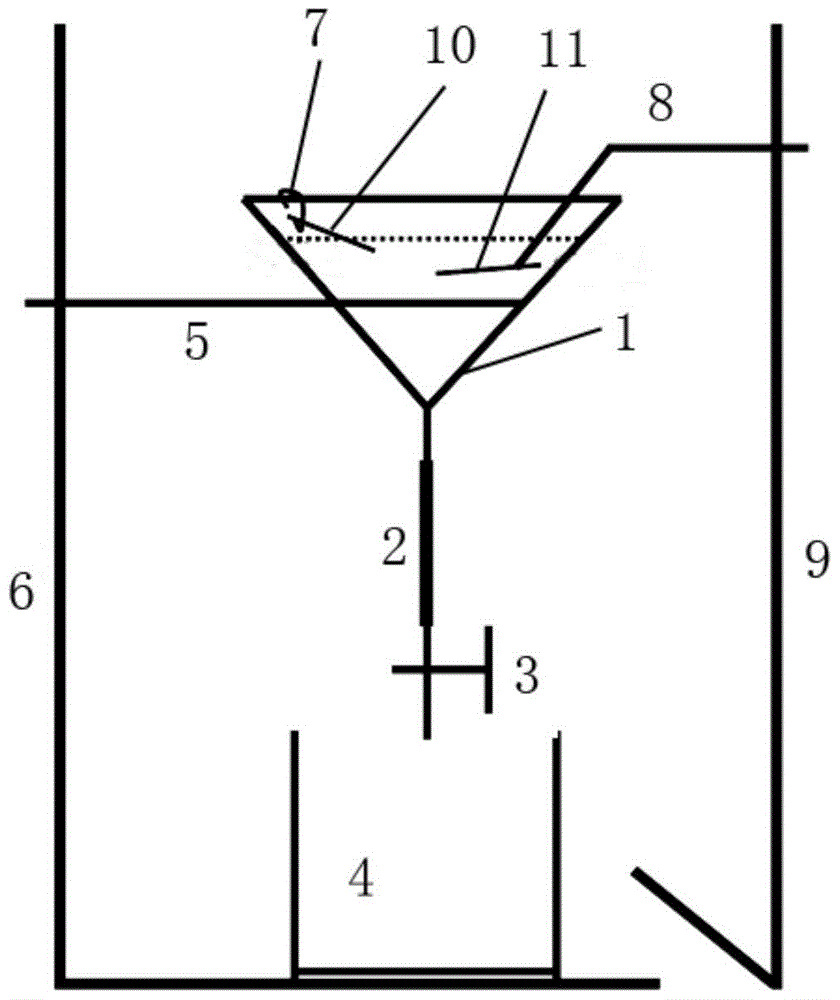

[0037] 3)第一基片10放置:把清洗干净的玻片(即第一基片10)放置在铜线折叠的第一基片夹7上,再把第一基片夹7固定到漏斗口边缘,让玻片正面朝上,正面1 / 3面积左右沉浸在去离子水里,正面与液面夹角呈20~30度。

[0038] 4)第二基片11放置:把清洗干净的硅片(即第二基片11)放置在铜线折叠的第二基片夹8上,再把第二基片夹8固定到第二基片夹支架9上,让硅片正面朝上,硅片全部沉浸在去离子水里,并远离第一基片10,正面与液面夹角呈2~5度,顶部离液面0.5~1.0cm。

[0039] 5)PS球溶液配制:将直径为360nm、初始质量浓度为5%的PS球溶液(购自苏州微纳生物科技有限公司)用乙醇稀释成3%。手动左右摇晃滴管,时间尽量长点使溶液混合均匀。

[0040] 6)单层PS球排列:利用移液枪,往稀释后的PS球溶液里吸取7μL溶液,再将该溶液滴到第一基片10中上部。由于基片的倾斜,摊开在基片上的PS球溶液自动流到液面上。当液面平衡时,PS球具...

Embodiment 2

[0047] 1)玻片清洗:将10mm×15mm的玻片依次放在去离子水中超声清洗10min,在甲苯中超声10min,在去离子水中超声清洗10min,在丙酮中超声10min,在去离子水中超声清洗10min,在乙醇中超声10min,在去离子水中超声清洗10min。再把玻片放置到SDS(10%浓度)溶液里浸泡12h,增加亲水性。取出在去离子水中超声清洗3次,每次5min。上述超声机工作功率100W,频率40kHz。

[0048] 2)第一基片10放置:把清洗干净的玻片放置在铜线折叠的第一基片夹7上,再把第一基片夹7固定到漏斗口边缘,让玻片正面朝上,正面1 / 3面积左右沉浸在去离子水里,正面与液面夹角呈20~30度。

[0049] 3)第二基片11放置:把清洗干净的玻片放置在铜线折叠的第二基片夹8上,再把第二基片夹8固定到第二基片夹支架9上,让玻片正面朝上,玻片全部沉浸在去离子水里,并远离第一基片10,正面与液面夹角呈2~5度,顶部离液面0.5~1.0cm。

[0050] 4)PS球溶液配制:将直径为360nm、初始质量浓度为5%的PS球溶液(购自苏州微纳生物科技有限公司)用乙醇稀释成3%。手动左右摇晃滴管,时间尽量长点使溶液混合均匀。

[0051] 5)单层PS球排列:利用移液枪,往稀释后的PS球溶液里吸取7μL溶液,再将该溶液滴到第一基片10中上部。由于基片的倾斜,摊开在基片上的PS球溶液自动流到液面上。当液面平衡时,PS球具有最低能量,由于漏斗里水面面积足够大,此时稀释均匀的PS球会以单层结构分散在液面。

[0052] 6)单层PS球密排:利用移液枪,往液面上没有PS球排列的地方滴入1~3滴浓度为0.25%的十二烷基硫酸钠,每滴7.5μL,以驱使PS球密排。

[0053] 7)单层PS球密排面转移:缓慢平移第二基片夹支架9,让第二基片11移到PS球密排面正下方。旋转可控流量阀门,让水以约45μL / min的流速流进容器。由于液面的下沉,PS球将覆盖到第二基片11表面。基片的轻微倾斜,使PS球之间空隙的水往同个方向流动,水流带动PS球,使它们更加致密排列。

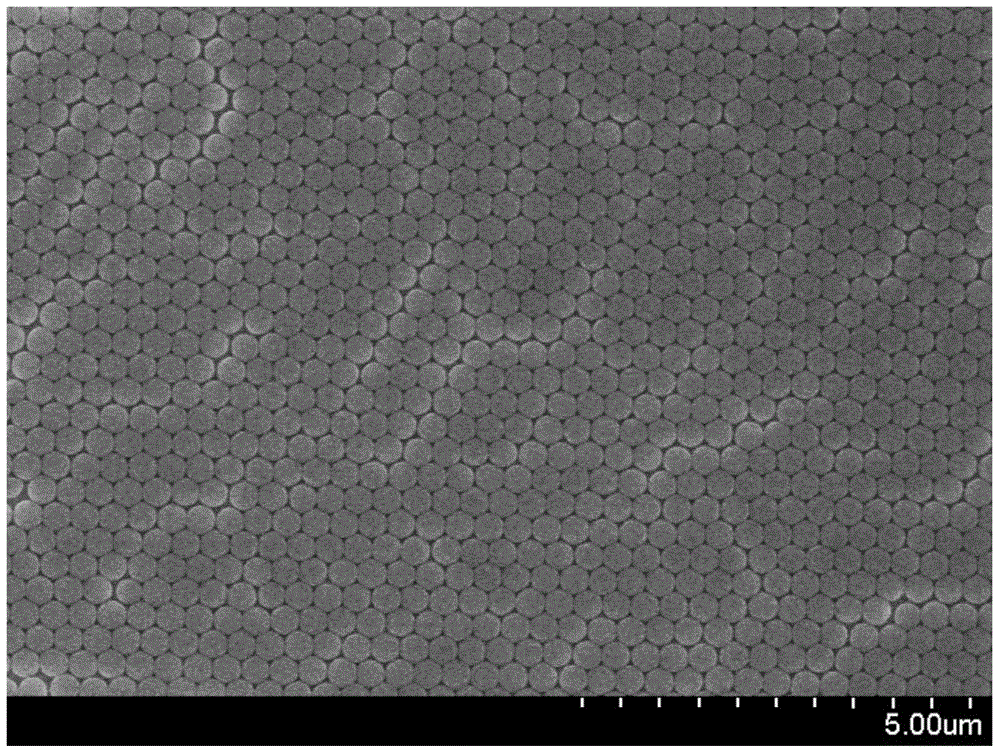

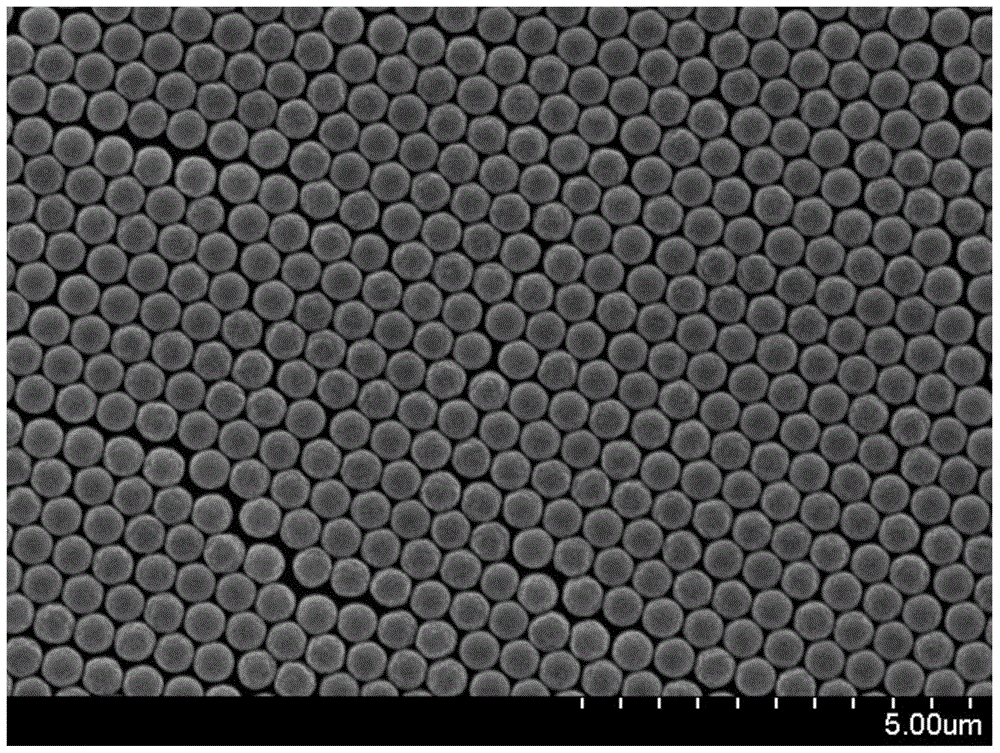

[0054]8) Drying of the single-layer PS ball close-packed surface: After the liquid s...

Embodiment 3

[0060] 1) Cleaning of glass slides: put the slides of 10mm×15mm in deionized water for 10 minutes, ultrasonic cleaning in toluene for 10 minutes, ultrasonic cleaning in deionized water for 10 minutes, ultrasonic cleaning in acetone for 10 minutes, and ultrasonic cleaning in deionized water for 10 minutes. , sonicated in ethanol for 10 min, and ultrasonically cleaned in deionized water for 10 min. Then place the slide in SDS (10% concentration) solution and soak for 12 hours to increase the hydrophilicity. Take it out and ultrasonically clean it in deionized water 3 times, 5 min each time. The working power of the above ultrasonic machine is 100W, and the frequency is 40kHz.

[0061] 2) Placement of the first substrate 10: place the cleaned glass slide on the first substrate holder 7 folded with copper wires, and then fix the first substrate holder 7 to the edge of the funnel mouth, so that the glass slide faces upwards, About 1 / 3 of the front surface is immersed in deionized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com